Composite polymer particle and method for preparing same

A composite polymer and particle technology, which is applied in pharmaceutical formulations, cosmetic preparations, toiletry preparations, etc., can solve the problems of inability to obtain defense effects, usability and transparency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

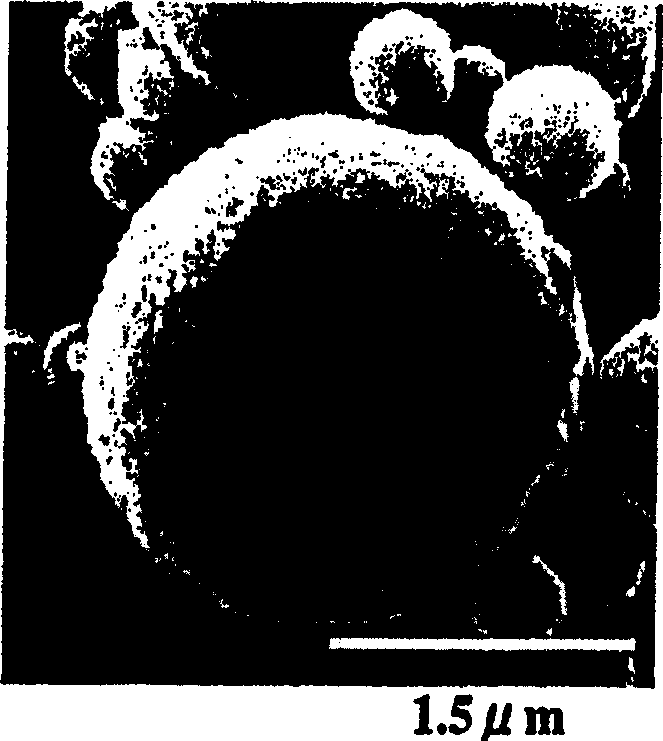

Embodiment 1

[0102] Using a glass bead mill, 60 g of silicon-treated zinc oxide (MZ-507S) manufactured by Teika was stirred for 3 hours in 45 g of lauryl methacrylate (SP value 8.7) and 45 g of ethylene glycol dimethacrylate (manufactured by Otsuka Electronics Co., Ltd. The average particle diameter of zinc oxide measured by ELS-8000 is 0.3 μm). Thereafter, 3 g of lauroyl peroxide were added. 20 g of sodium lauryl sulfate was dissolved in 1500 g of ion-exchanged water, added to the above-mentioned zinc oxide slurry, and dispersed using a Mielder (the average particle diameter of the emulsion measured with LA-910 manufactured by Horiba Seisakusho was 1.6 μm). Next, put the dispersion into a 2000mL separable beaker, replace it with nitrogen, and heat up to 70°C while stirring at 200r / min, keep it at 70°C for 10 hours, then raise the temperature to 80°C, and heat up to 80°C under nitrogen at 80°C. Polymerization was carried out under atmosphere for 10 hours. After the polymerization, the so...

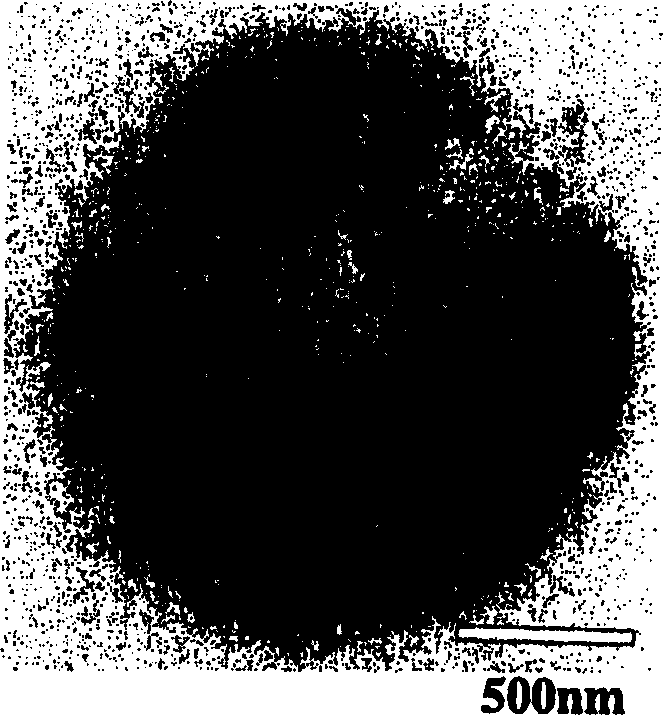

Embodiment 2

[0105] Using a glass bead mill, 90 g of Teika silicon-treated zinc oxide (MZ-507S) was mixed with 45 g of octadecyl methacrylate (SP value 8.7), 45 g of 1,6-hexanediol dimethacrylate, and 30 g of heptane. Stirring was carried out for 3 hours (the average particle diameter of zinc oxide measured with ELS-8000 manufactured by Otsuka Electronics Co., Ltd. was 0.4 μm). Thereafter, 3 g of lauroyl peroxide were added. Dissolve 15 g of sodium cocoyl methyl taurate in 1500 g of ion-exchanged water, add it to the above-mentioned zinc oxide slurry, and disperse it using a homogenizer (the average particle diameter of the emulsion measured with LA-910 manufactured by Horiba Manufacturing Co., Ltd. is 1.6 μm) ). Next, put the dispersion into a 2000mL separable beaker, replace it with nitrogen, and heat up to 70°C while stirring at 200r / min, keep it at 70°C for 10 hours, then raise the temperature to 80°C, and heat up to 80°C under nitrogen at 80°C. Polymerization was carried out under a...

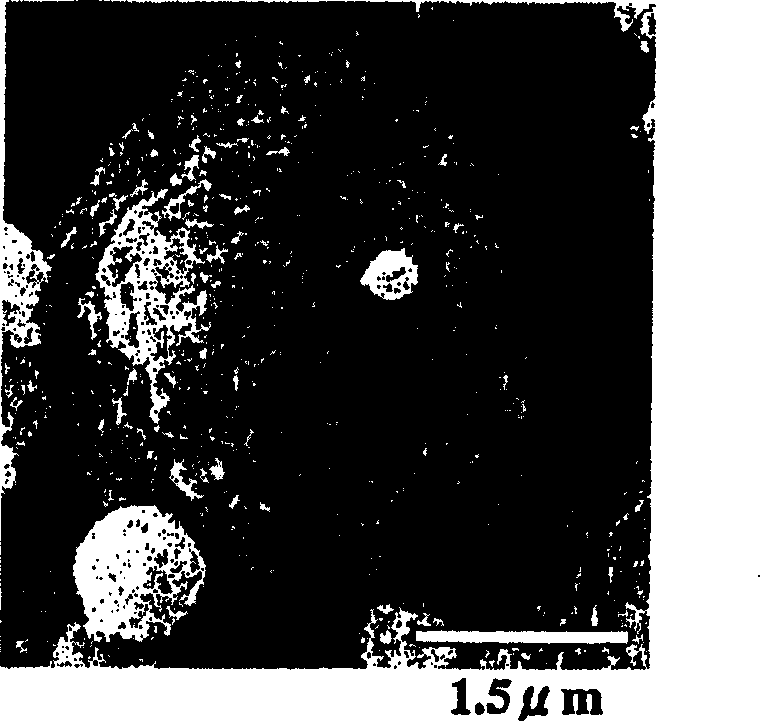

Embodiment 3

[0107] Using a glass bead mill, 40 g of silicon-treated zinc oxide (MZ-507S) manufactured by Teika was stirred for 3 hours in 30 g of lauryl methacrylate (SP value 8.7) and 30 g of ethylene glycol dimethacrylate (manufactured by Otsuka Electronics Co., Ltd. The average particle diameter of zinc oxide measured by ELS-8000 is 0.3 μm). Thereafter, 1.5 g of 2,2'-azobis-2,4-dimethylvaleronitrile were added. Dissolve 30g of polyvinyl alcohol (EG-30 manufactured by Nippon Synthetic Chemical Industry Co., Ltd.) and 1g of sodium stearyl methyl taurate in 500g of ion-exchanged water, add them to the above-mentioned zinc oxide slurry, and disperse them using Mielda- (made by Dokujo Works). The average particle diameter of the emulsion measured by LA-910 is 2.0 μm). Next, put the dispersion into a 1000mL separable beaker, replace it with nitrogen, heat up to 60°C while stirring at 200r / min, keep it at 60°C for 2 hours, then raise the temperature to 80°C, Polymerization was carried out u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com