Anti-ultraviolet polyethylene electric cable insulation material and preparation method thereof

A cable insulation and anti-ultraviolet technology, applied in the field of polymer materials, can solve the problems of shortened service life, failure to meet protection, insulation requirements, aging of the outer insulation layer, etc., to achieve uniform color and luster, excellent anti-ultraviolet performance and weather resistance, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

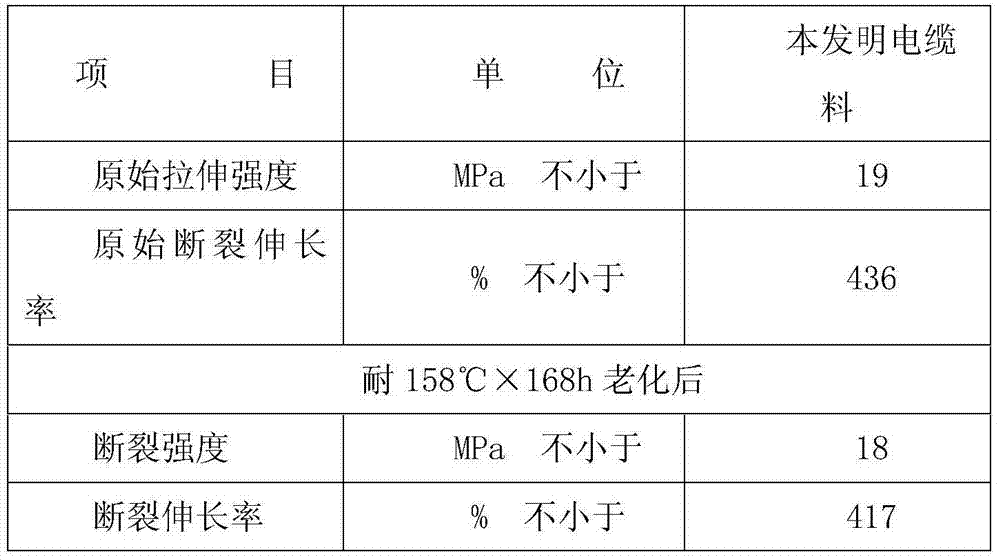

Examples

Embodiment Construction

[0013] The present invention will be described in detail below through specific examples.

[0014] An anti-ultraviolet polyethylene cable insulation material, made of the following raw materials in parts by weight (kg): linear low-density polyethylene 40, high-density polyethylene 14, antioxidant 10351, PE wax 4, general-purpose polystyrene 16, Polyisobutylene 2, zinc stearate 3, dioctyl ester 22, dibutyl phthalate 14, zinc borate 2, antioxidant DLTP1, anti-scorch agent CTP2, additive 6;

[0015] The auxiliary agent is made of the following raw materials in parts by weight (kg): montmorillonite 12, sodium hexametaphosphate 1, silane coupling agent KH-5501, titanium diboride 2, brown corundum powder 2, sodium selenite 2. Molybdenum trioxide 1, bauxite 2, zinc stearate 1, tributyl citrate 1, wintergreen oil 0.1; the preparation method is to send montmorillonite into a calciner and calcinate at 700-730°C for 3- 4 hours, take it out, send it into 10-15% hydrochloric acid and soak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com