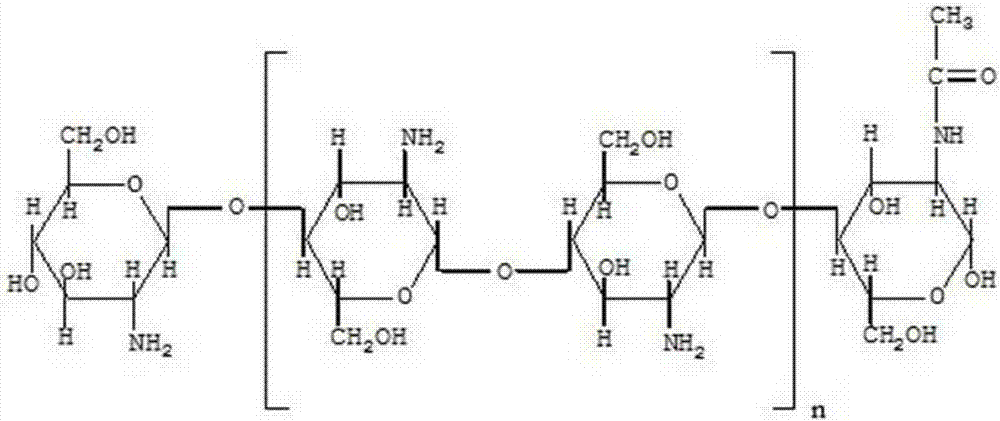

Method of preparing composite preservative film or coating from chitosan and alcohol soluble corn protein

A zein and composite fresh-keeping technology, which is applied in the direction of coating and protecting fruits/vegetables with a coating protective layer, can solve problems such as poor moisture resistance and UV protection performance, affecting freshness preservation effect, and poor mechanical properties. To achieve the effect of simple and reasonable raw material ratio, food safety, non-toxic and harmless, and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

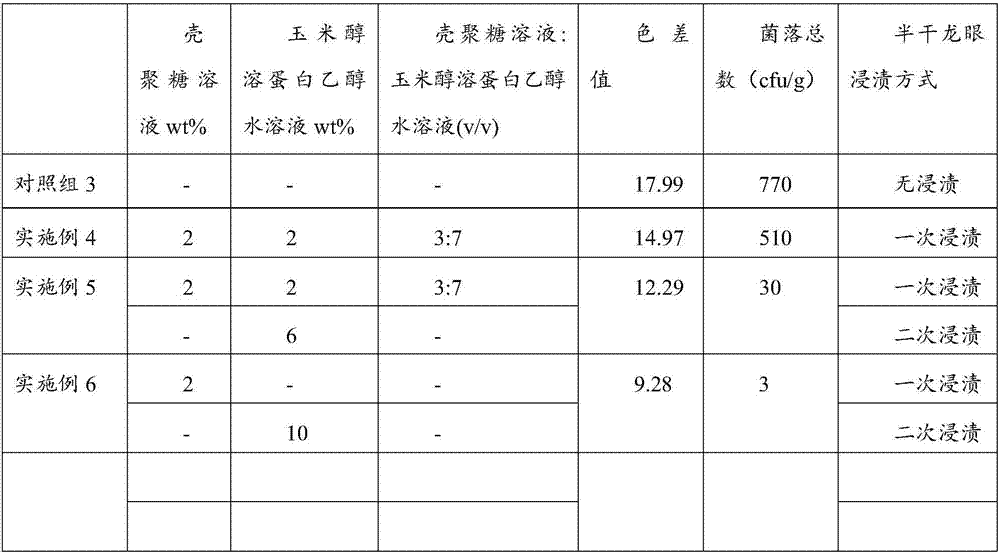

Examples

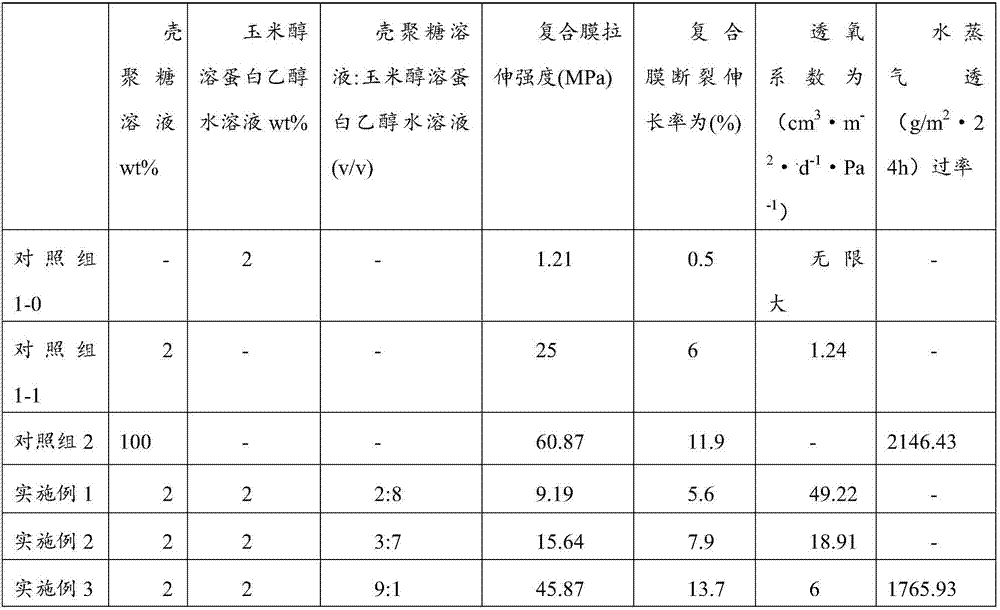

Embodiment 1

[0056] A kind of preparation method using chitosan zein as raw material composite preservative film or coating, comprises the following steps:

[0057] (1) 2g chitosan is joined in the acetic acid aqueous solution of 2% (w / v) of 100g, add 0.4g glycerol simultaneously, stir until dissolving completely, make 2wt% chitosan solution;

[0058] (2) 2 g of zein was added to 100 g of 85% (w / v) ethanol aqueous solution, and 0.4 g of glycerin was added at the same time, and stirred until completely dissolved to obtain 2 wt % zein ethanol aqueous solution;

[0059] (3) Mix the chitosan solution prepared in step (1) with the zein ethanol aqueous solution prepared in step (2) at a volume ratio of 2:8, and stir at 300 r / min for 30 minutes at 50 ° C. Minutes later, remove the gas in the mixed film liquid with ultrasonic vibration for 20 min, and prepare the chitosan-based composite fresh-keeping film film liquid;

[0060] (4) casting the composite plastic wrap prepared through the above ste...

Embodiment 2

[0065] A kind of preparation method taking chitosan zein as raw material composite plastic wrap or coating comprises the following steps:

[0066] (1) 2g chitosan is joined in the acetic acid aqueous solution of 2% (w / v) of 100g, add 0.4g glycerol simultaneously, stir until dissolving completely, make 2wt% chitosan solution;

[0067] (2) 2 g of zein was added to 100 g of 85% (w / v) ethanol aqueous solution, and 0.4 g of glycerin was added at the same time, and stirred until completely dissolved to obtain 2 wt % zein ethanol aqueous solution;

[0068] (3) The chitosan solution prepared in step (1) and the zein ethanol aqueous solution prepared in step (2) were mixed at a volume ratio of 3:7, and stirred at a speed of 300 r / min for 30 minutes at 50° C. Minutes later, remove the gas in the mixed film liquid with ultrasonic vibration for 20 min, and prepare the chitosan-based composite fresh-keeping film film liquid;

[0069] (4) casting the composite plastic wrap prepared through...

Embodiment 3

[0074] A kind of preparation method using chitosan zein as raw material composite preservative film or coating, comprises the following steps:

[0075] (1) 2g chitosan is joined in the acetic acid aqueous solution of 2% (w / v) of 100g, add 0.4g glycerol simultaneously, stir until dissolving completely, make 2wt% chitosan solution;

[0076] (2) 2 g of zein was added to 100 g of 85% (w / v) ethanol aqueous solution, and 0.4 g of glycerin was added at the same time, and stirred until completely dissolved to obtain 2 wt % zein ethanol aqueous solution;

[0077] (3) The chitosan solution prepared in step (1) and the zein ethanol aqueous solution prepared in step (2) were mixed at a volume ratio of 9:1, and stirred at a speed of 300 r / min for 30 minutes at 50° C. Minutes later, remove the gas in the mixed film liquid with ultrasonic vibration for 20 min, and prepare the chitosan-based composite fresh-keeping film film liquid;

[0078] (4) casting the composite plastic wrap prepared th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com