Double-hollow glass ceiling module with film suspended therein

A double-hollow, inner glass technology, applied to building components, roof cladding, insulation, etc., can solve the problems of daylighting glass ceiling deformation, surface cleaning, etc., to achieve surface cleaning and easy maintenance, reliable operation, and reasonable sealing and installation structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

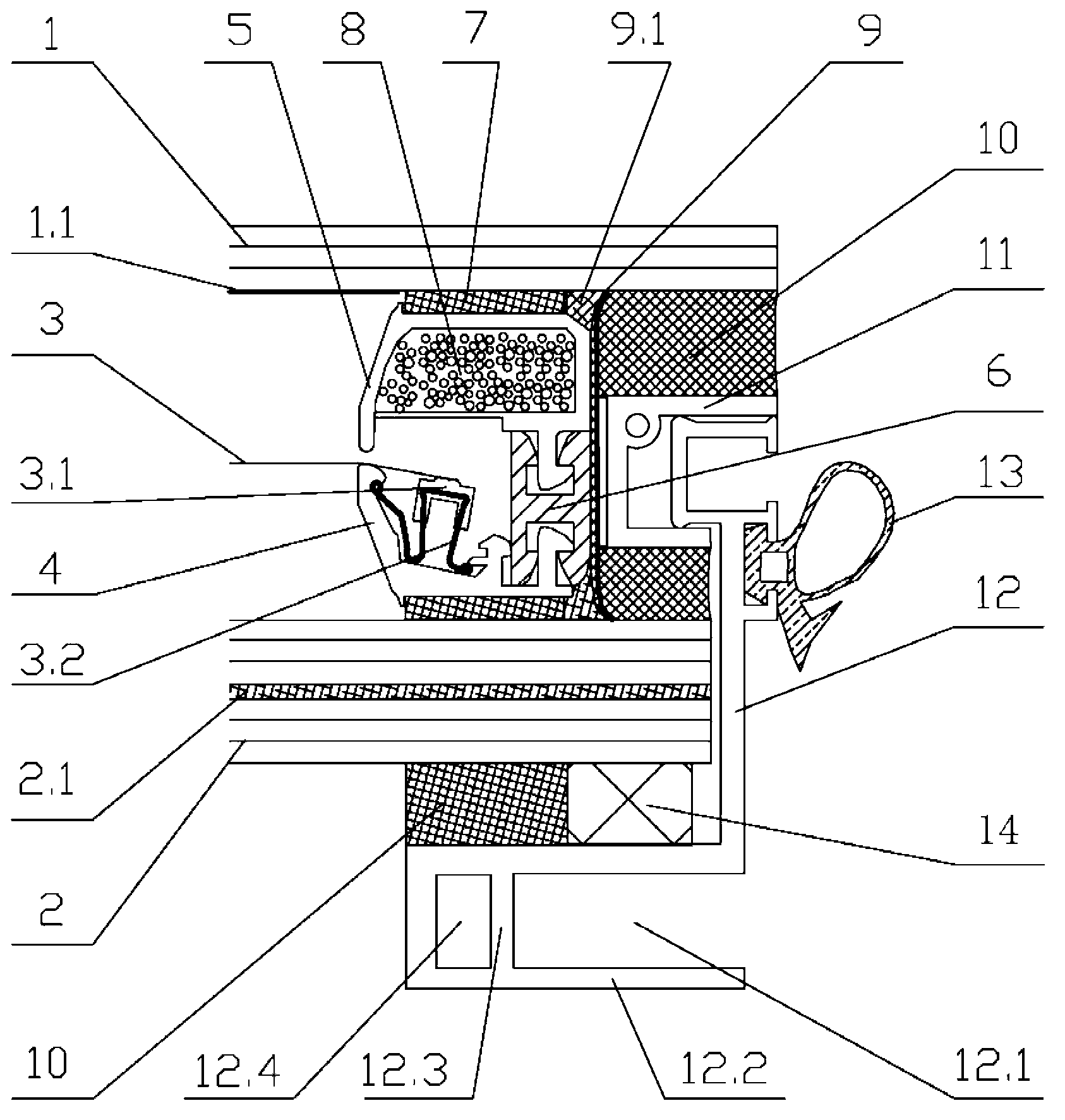

[0046] Such as figure 1 As shown, the double hollow glass ceiling module of the present invention is manufactured and assembled in the manufacturing workshop according to the design requirements.

[0047] The double hollow glass unit with the inner suspension film is assembled through the assembly of the suspension film, and then jointed with butyl glue and pasted with butyl tape to complete the packaging of the first sealing layer.

[0048] On the inner surface of the outer layer of glass 1, the drying frame (molecular sieve frame) 5 is fixed on the surrounding edges of the glass with quick-sticking structural adhesive tape 7. Ensure that there is a certain distance between the outer edge of the drying frame and the outer edge of the glass to ensure that there is enough sealing space outside. The inner cavity of the pasted drying frame has been filled with molecular sieves according to the construction requirements of desiccant 8.

[0049] On the inner surface of the inner ...

Embodiment 2

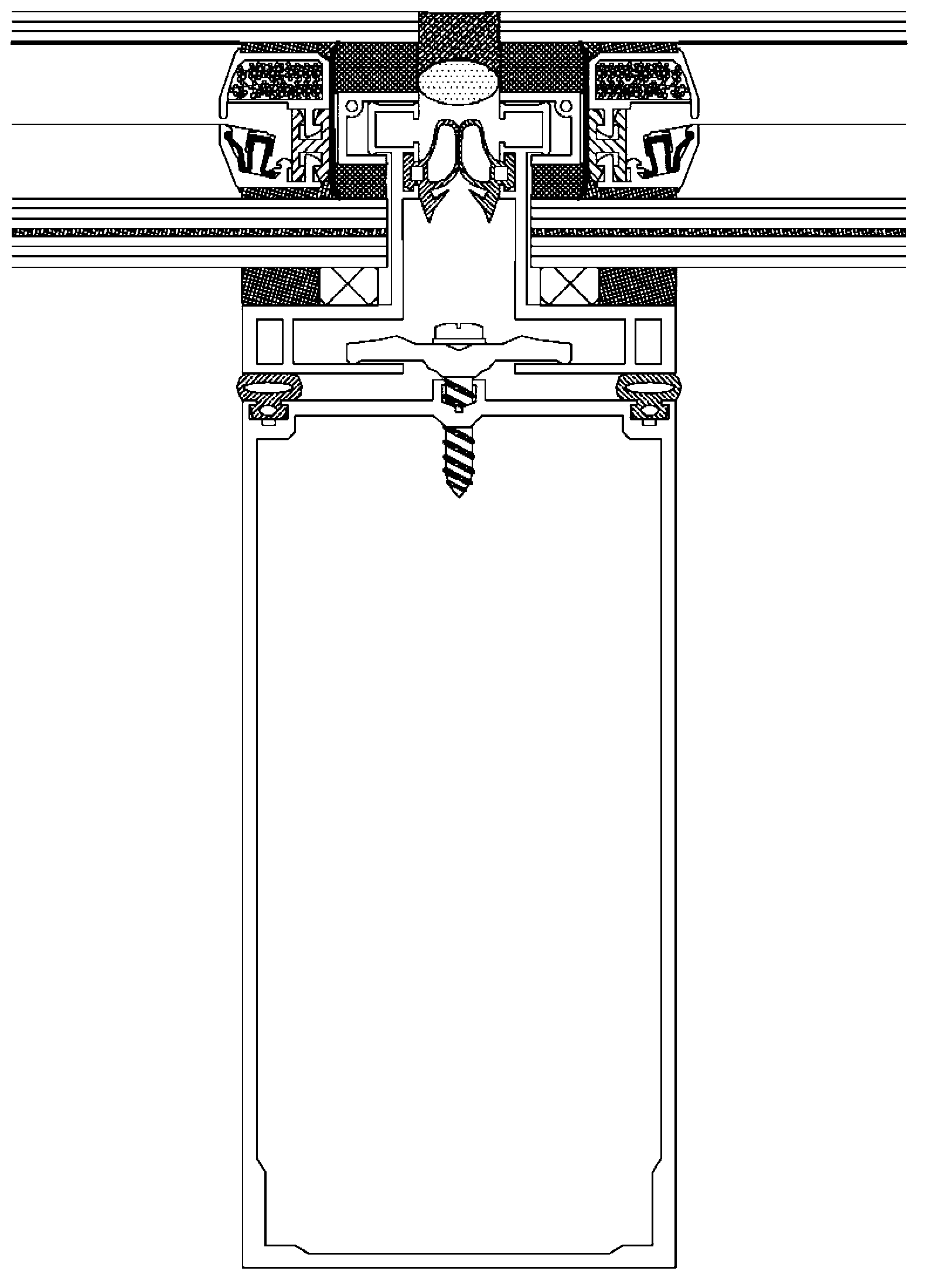

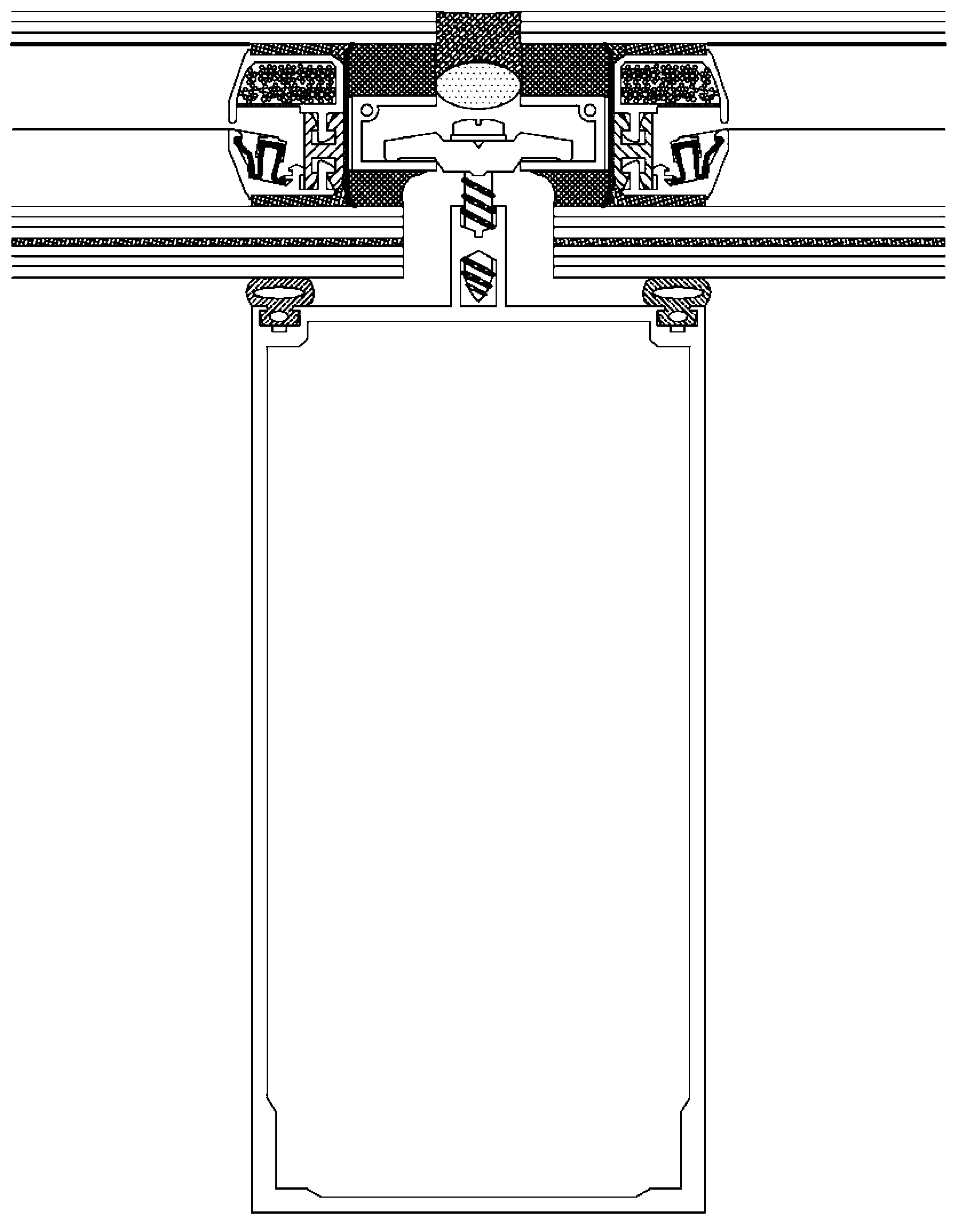

[0061] Such as Figure 4 As shown, it is a sectional view of glass modules for other facade applications provided by the present invention. As described in Example 1, the double-hollow glass ceiling module with the inner suspending film is manufactured and assembled in the workshop according to the design requirements.

[0062] Such as Figure 5 , Figure 6 , Figure 7 As shown, the positioning side baffles of the installation structure frame are appropriately lengthened and aligned with the outer surface of the outer glass. While the baffle and the glass form a good sealing surface, the support and protection of the outer glass of the baffle are increased.

[0063] The system plate of the present invention is sent to the curtain wall assembly workshop for pre-assembly. The fixing plate of the C-shaped groove of the structural frame is pressed by the pressing plate and fastened and positioned by bolts or screws. After installing seals or other functional accessories acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com