Cool three-phase emulsification type sun-screen cosmetic and preparation method thereof

An emulsified, cosmetic technology, applied in cosmetic preparations, cosmetics, cosmetic preparations, etc., can solve the problems of sticky sunscreen products, poor user experience, etc., and achieve excellent sweat resistance, excellent UV protection effect, stable Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the above-mentioned refreshing three-phase emulsified sunscreen cosmetics, which comprises:

[0025] Step 1, disperse the selected dose of surfactant and sunscreen in the oil in the container, and heat to 80-85°C, keep warm and stir for 10 to 15 minutes until it is evenly mixed, then stir and cool to 40-42°C, Insulation standby;

[0026] Step 2, take another container and disperse the selected dose of polyol and thickener in water, heat to 80-90°C, keep warm and stir for 20 to 30 minutes until it is evenly mixed, then stir and cool to 40-42°C, keep warm for later use ;

[0027] Step 3, stir the water phase mixture prepared in step 2 at high speed, then slowly filter the oil phase mixture prepared in step 1 into the water phase mixture, then homogenize for 5 minutes, scrape off the uneven material, and then stir for homogenization After 8 minutes, cool to 30-35°C and discharge after passing the inspection.

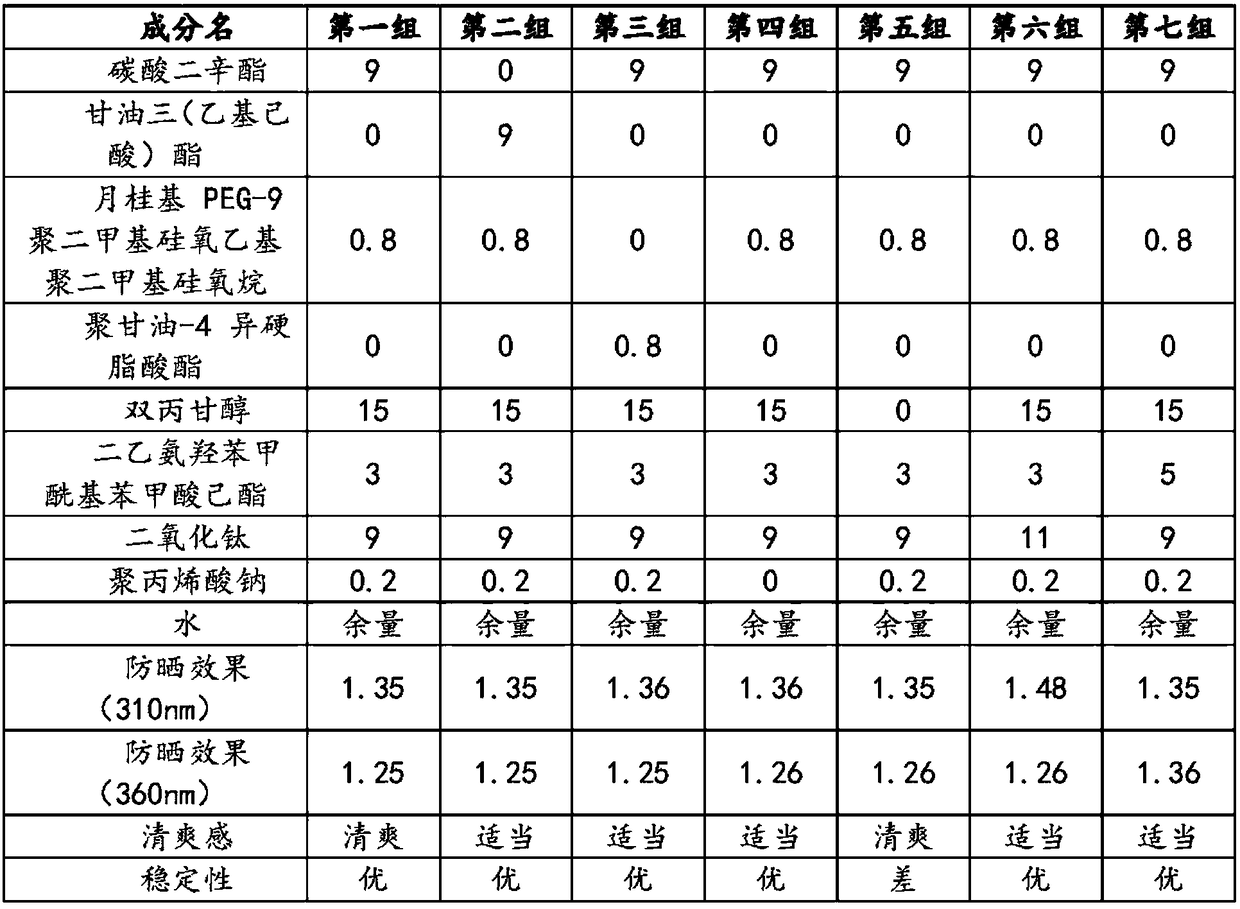

[0028] Performance evaluation test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com