Flash rust-proof acrylic roof waterproof coating and preparation method thereof

A waterproof coating and acrylic technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of easy flash rust and poor anti-flash rust effect of waterproof coatings, and achieve durable waterproof effect, strong adhesion, human health and surrounding environment harmless effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

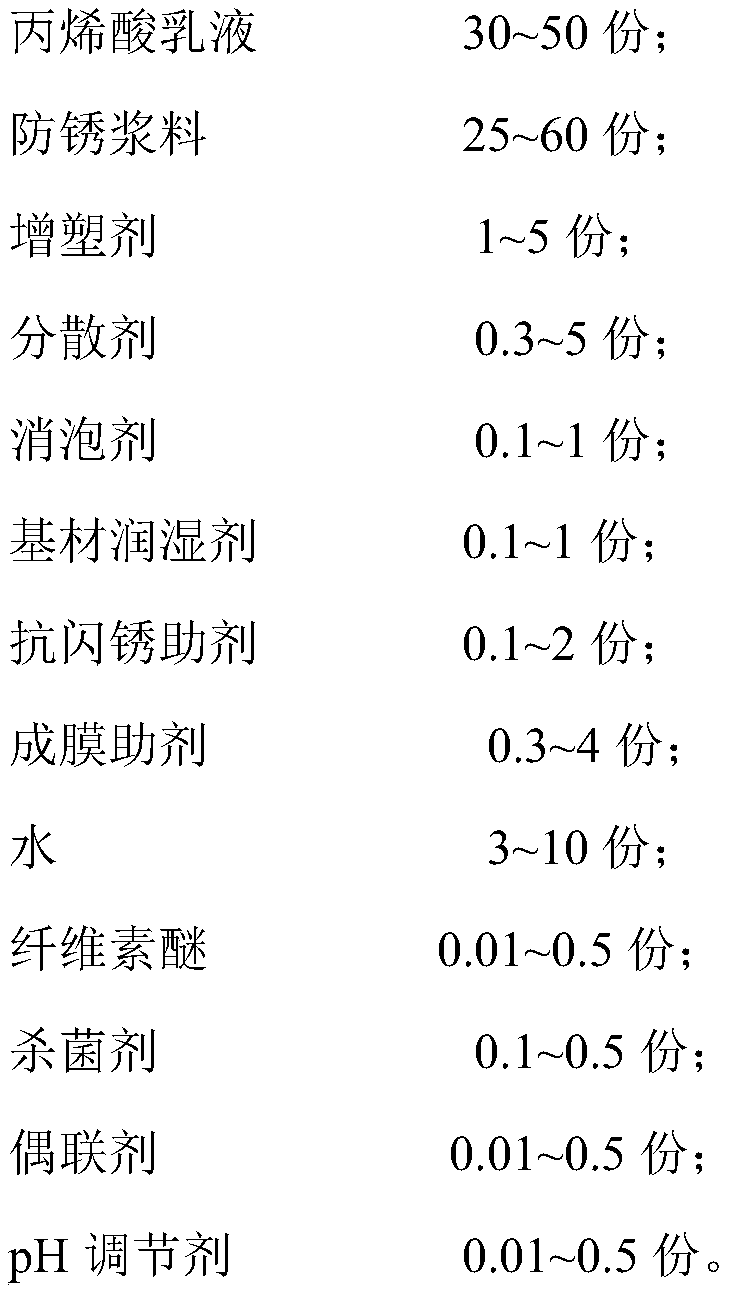

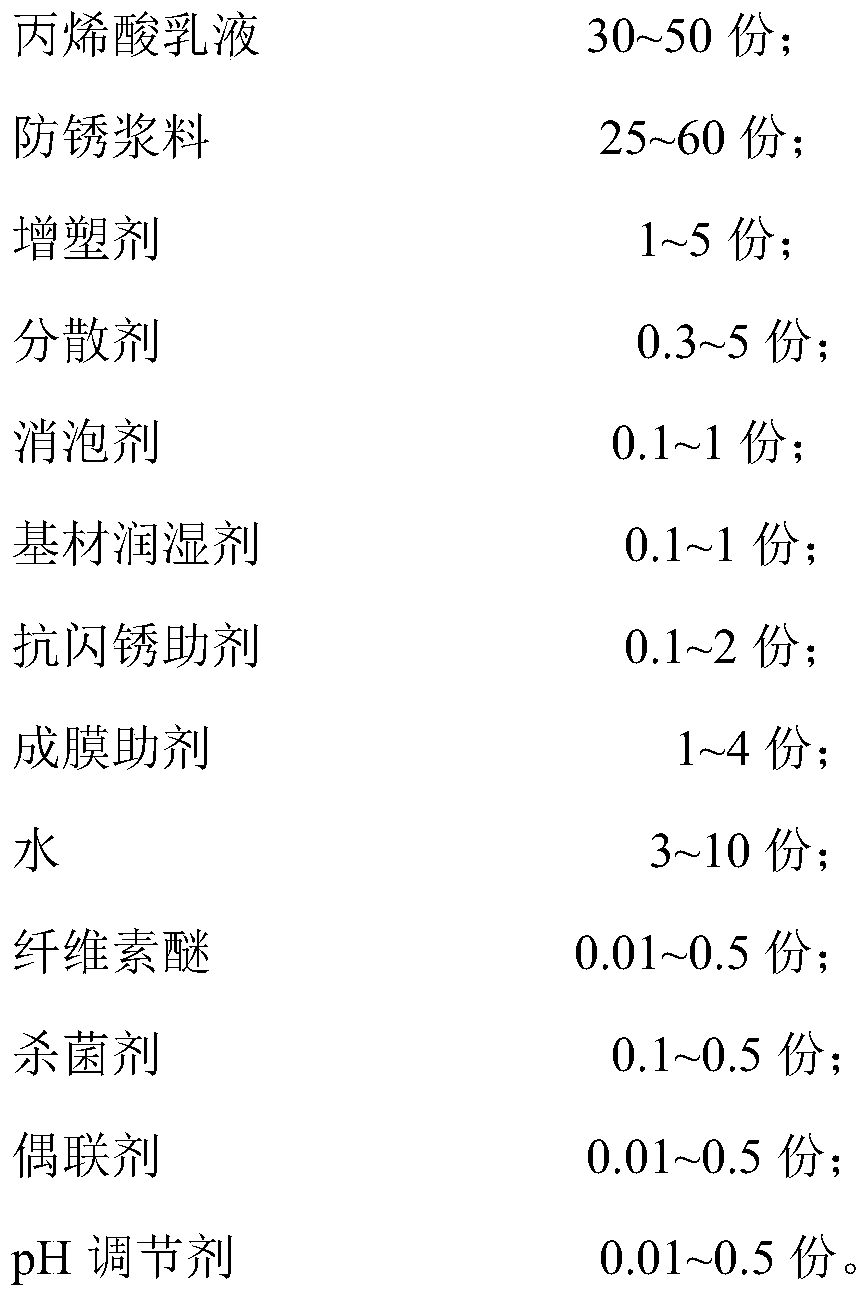

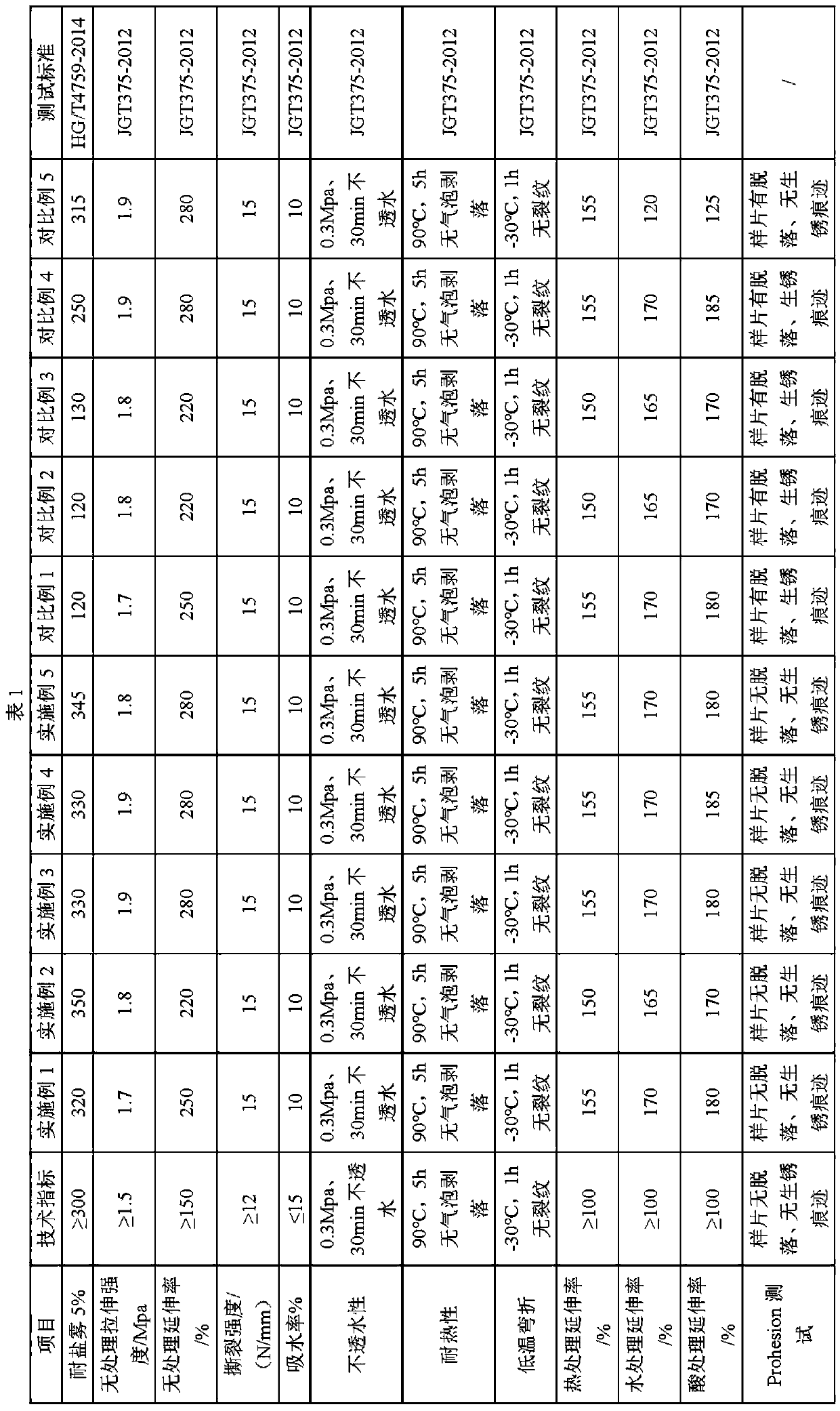

Embodiment 1

[0033] This embodiment provides a roof waterproof coating with anti-flash rust function, which specifically includes the following raw materials in parts by weight: 35.2 parts of acrylic emulsion, 50 parts of antirust slurry, 5 parts of plasticizer, 0.3 part of dispersant, disinfectant 0.2 parts of foaming agent, 0.15 parts of substrate wetting agent, 0.5 parts of anti-flash rust additive, 0.3 parts of film-forming aid, 8 parts of deionized water, 0.15 part of cellulose ether, 0.1 part of fungicide, and 0.05 part of coupling agent , 0.05 parts of pH regulator.

[0034] The anti-rust slurry is composed of the following components by weight: 20 parts of acrylic emulsion, 2 parts of zinc phosphate, 5 parts of aluminum tripolyphosphate, 43.4 parts of 800 mesh heavy calcium, 5 parts of titanium iron powder, 20 parts of deionized water, 4.5 parts of dispersant, 0.1 part of defoamer.

[0035] Wherein, the acrylic emulsion is pure acrylic emulsion for U.S. Dow Rohm and Haas Bailimo E...

Embodiment 2

[0056] This embodiment provides a roof waterproof paint with anti-flash rust function, which specifically includes the following raw materials in parts by weight: 30.2 parts of acrylic emulsion, 55 parts of antirust slurry, 5 parts of plasticizer, 0.3 part of dispersant, disinfectant 0.2 parts of foaming agent, 0.15 parts of substrate wetting agent, 0.5 parts of anti-flash rust additive, 0.3 parts of film-forming aid, 8 parts of deionized water, 0.15 part of cellulose ether, 0.1 part of fungicide, and 0.05 part of coupling agent , 0.05 parts of pH regulator.

[0057] The anti-rust slurry is composed of the following components by weight: 20 parts of acrylic emulsion, 2 parts of zinc phosphate, 5 parts of aluminum tripolyphosphate, 43.4 parts of 800 mesh heavy calcium, 5 parts of titanium iron powder, 20 parts of deionized water, 4.5 parts of dispersant, 0.1 part of defoamer.

[0058] Wherein, the acrylic emulsion is pure acrylic emulsion for U.S. Dow Rohm and Haas Bailimo EC4...

Embodiment 3

[0071] This embodiment provides a roof waterproof coating with anti-flash rust function, which specifically includes the following raw materials in parts by weight: 40.2 parts of acrylic emulsion, 45 parts of antirust slurry, 5 parts of plasticizer, 0.3 part of dispersant, disinfectant 0.2 parts of foaming agent, 0.15 parts of substrate wetting agent, 0.5 parts of anti-flash rust additive, 0.3 parts of film-forming aid, 8 parts of deionized water, 0.15 part of cellulose ether, 0.1 part of fungicide, and 0.05 part of coupling agent , 0.05 parts of pH regulator.

[0072] The anti-rust slurry is composed of the following components by weight: 20 parts of acrylic emulsion, 2 parts of zinc phosphate, 5 parts of aluminum tripolyphosphate, 43.4 parts of 800 mesh heavy calcium, 5 parts of titanium iron powder, 20 parts of deionized water, 4.5 parts of dispersant, 0.1 part of defoamer.

[0073] Wherein, the acrylic emulsion is pure acrylic emulsion for U.S. Dow Rohm and Haas Bailimo E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com