Umbrella cloth and manufacturing method thereof

An umbrella cloth and fabric layer technology, which is applied in textiles, papermaking, textiles, fabrics, etc., can solve the problems of yellowing of the base cloth, affecting product quality, etc., and achieve the effects of not easy to yellowing, good waterproof effect, and good anti-ultraviolet effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

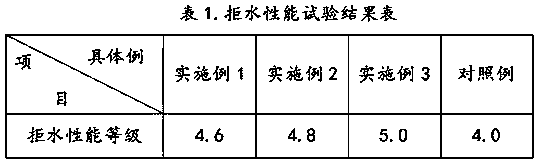

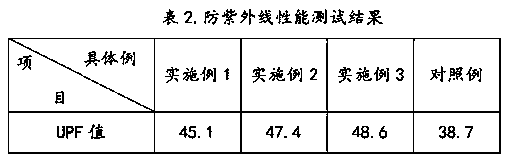

Embodiment 1

[0049] An umbrella cloth includes a fabric layer and a waterproof layer. The fabric layer is blended and woven by polyester fiber and acrylic fiber in a mass ratio of 8:2, and the thickness of warp and weft is 190D. After pre-treatment, the fabric weight after dyeing and / or printing is 100-180g / m 2 . The waterproof layer is finished by a water-repellent finishing liquid.

[0050] The manufacturing method of the above umbrella cloth includes the following steps:

[0051] S1. Perform conventional pre-treatment, dyeing and / or printing on the grey fabric blended with polyester fiber and acrylic fiber, and obtain the pre-treated cloth after reduction washing, water washing and drying;

[0052] S2. Weigh 21.9 parts of polyurethane emulsion, 13.1 parts of polyacrylate emulsion, 7.0 parts of epoxy-modified silicone oil, 3.0 parts of polyether-modified silicone oil, 11.0 parts of isocyanate, 2.5 parts of adhesive, and mix and stir in parts by weight. Evenly formulate into a water-repellent...

Embodiment 2

[0057] An umbrella cloth, which is basically the same as the umbrella cloth of Example 1, except that the thickness of the warp yarn and the weft yarn of the woven fabric layer are both 200D. The content of each component in step S2 in the manufacturing process is 25.0 parts of polyurethane emulsion, 15.0 parts of polyacrylate emulsion, 10.5 parts of epoxy modified silicone oil, 4.5 parts of polyether modified silicone oil, 13.0 parts of isocyanate, adhesive 4.0 parts, 3.0 parts of nano zinc oxide; the concentration of the water-repellent finishing solution in step S3 is 30 g / L.

Embodiment 3

[0059] An umbrella cloth, which is basically the same as the umbrella cloth in Example 1, except that the thickness of the warp yarn and the weft yarn of the woven fabric layer are both 210D. The content of each component in step S2 in the manufacturing process is 28.1 parts of polyurethane emulsion, 16.9 parts of polyacrylate emulsion, 14.0 parts of epoxy modified silicone oil, 6.0 parts of polyether modified silicone oil, 15.0 parts of isocyanate, adhesive 5.5 parts, 4.5 parts of nano zinc oxide; the concentration of the water-repellent finishing solution in step S3 is 45 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com