Warm-keeping house

A technology of a thermal insulation layer and a thermal insulation layer is applied to a thermal house. It can solve the problems of large deformation coefficient, poor sealing effect, aesthetic fatigue, etc., and achieve the effects of strong waterproof and corrosion resistance, improved thermal insulation and air tightness, and enhanced thermal insulation function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

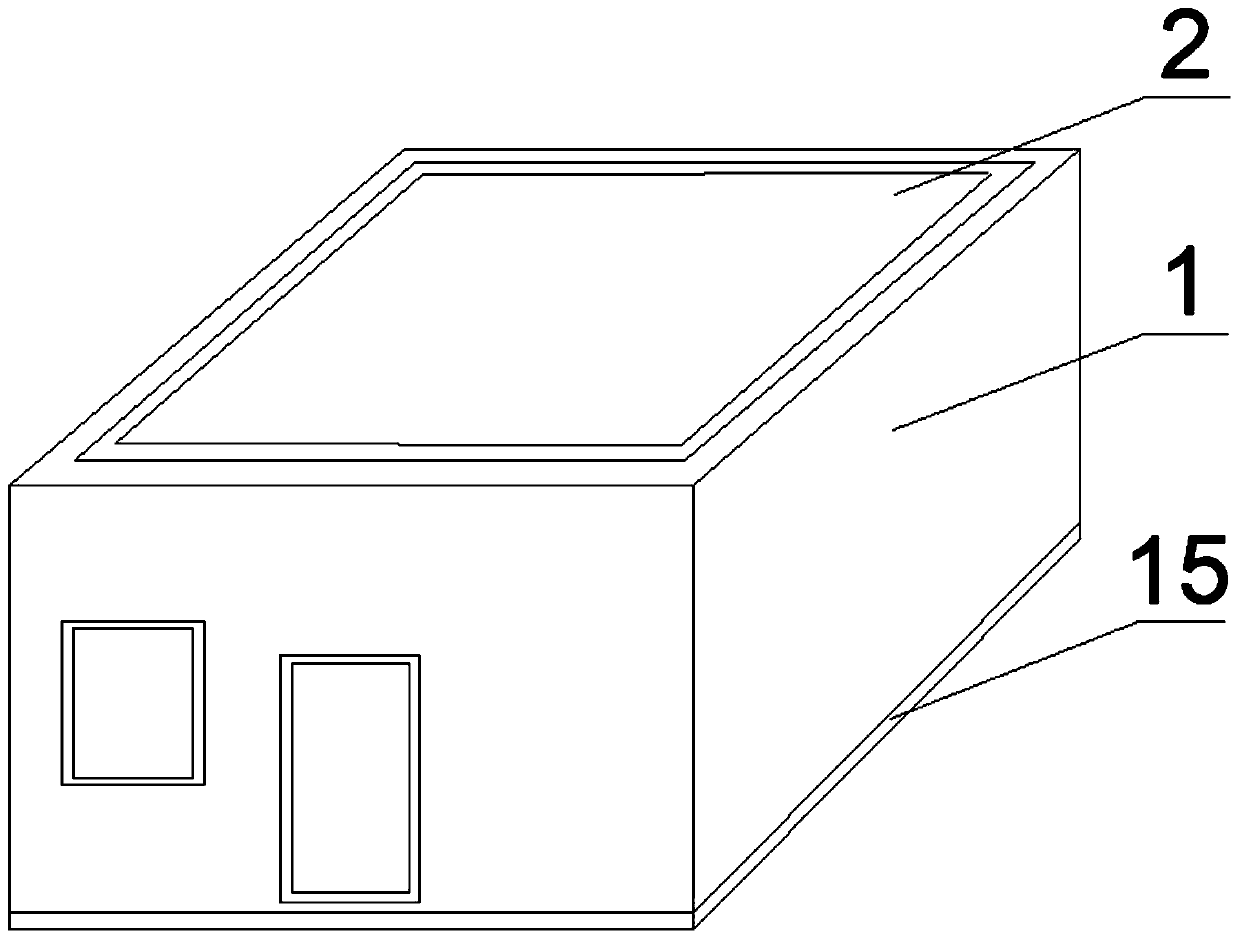

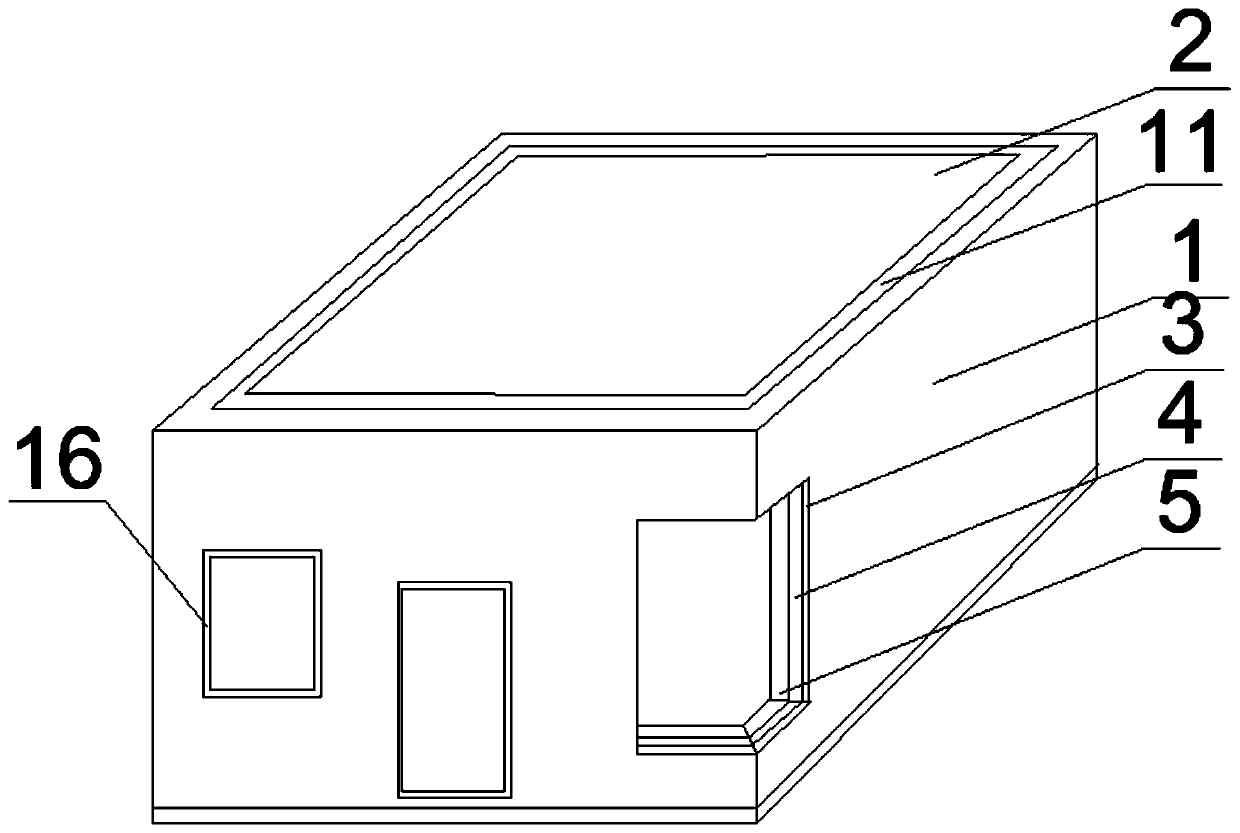

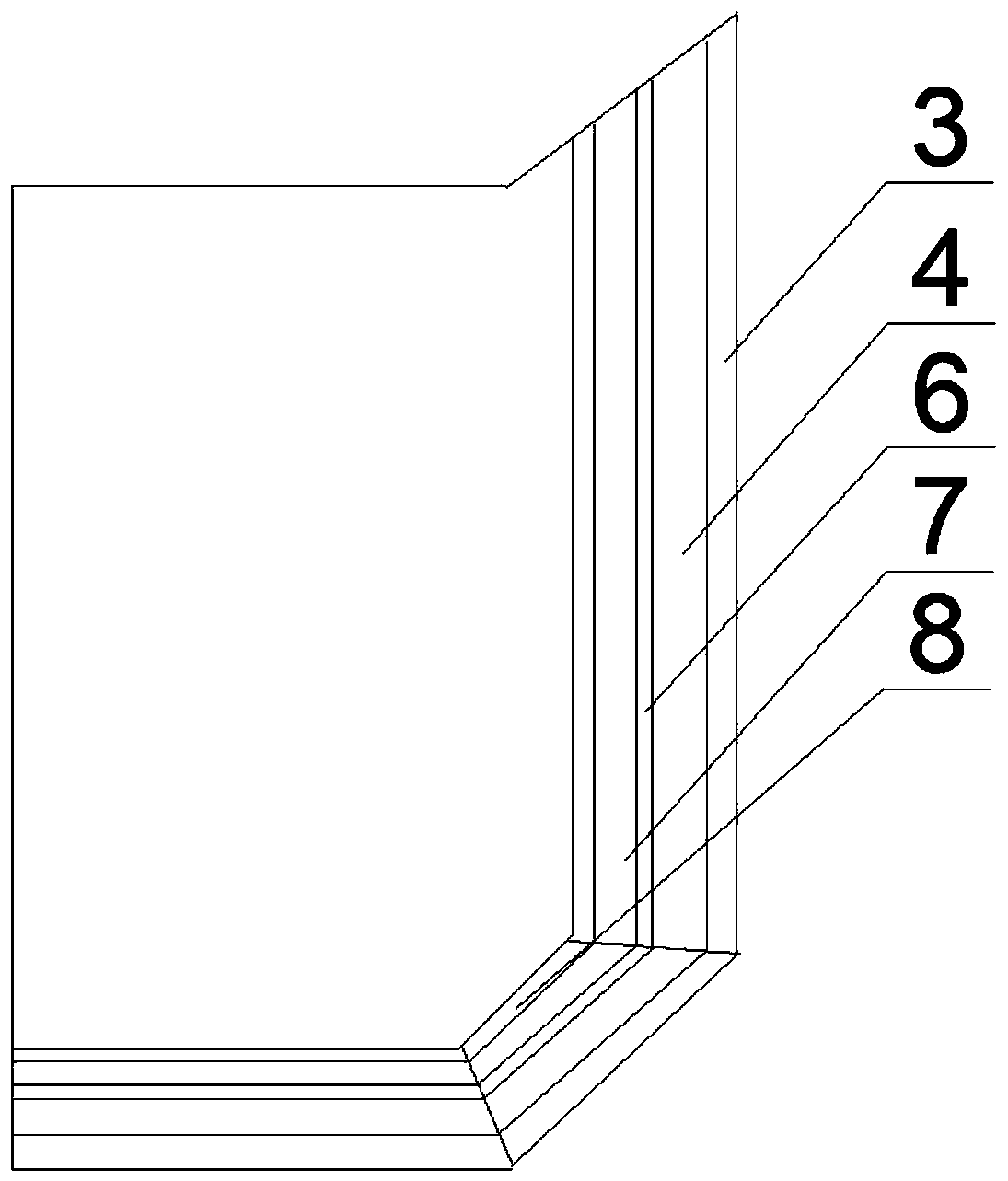

[0037] Specific implementation mode one: combine Figure 1-6 Describe this embodiment, a kind of heat preservation house, it comprises exterior wall 1 and ceiling 2; Ceiling 2 is arranged on the top of exterior wall; Exterior wall 1 comprises shell 3, waterproof layer 4 and thermal insulation layer (5) arranged in sequence from outside to inside.

[0038] The shell material of the present invention requires certain performance indicators such as low temperature resistance and wind resistance, and materials such as PVC artificial leather, glass, and polyurethane color steel sandwich panels need to be used. Taking PVC artificial leather as an example, it must achieve functions such as wind resistance, sun resistance, yellowing resistance, cold protection, water resistance, and UV resistance. The waterproof layer of the present invention uses a waterproof breathable film, and the waterproof breathable film plays the roles of waterproof, breathable and dustproof.

specific Embodiment approach 2

[0039] Specific implementation mode two: combination Figure 1-6 Describe this embodiment, the first difference between this embodiment and the specific embodiment is that the thermal insulation layer 5 includes the thermal insulation layer 6, the heating layer 7 and the thermal conduction layer 8, and the thermal insulation layer 6, the heating layer 7 and the thermal conduction layer 8 are arranged from the outside to the inside. set up.

[0040] Other compositions and connection methods are the same as those in Embodiment 1.

[0041] The thermal insulation layer of the present invention is an airgel thermal insulation layer, and the airgel or airgel felt is used to achieve a better thermal insulation effect and play a role of thermal insulation.

[0042] The heat conduction layer plays the role of interior decoration and heat conduction. Can use PVC artificial leather or decorative panels, floors, wall panels.

specific Embodiment approach 3

[0043] Specific implementation mode three: combination Figure 1-6 Describe this embodiment, the first difference between this embodiment and the specific embodiment is that the heating layer 7 includes a single anti-heating layer 9 and a graphene electric heating layer 10, the single anti-heating layer 9 is arranged on the side close to the insulation layer 6, and the graphite The vinyl electric heating layer 10 is arranged on a side close to the heat conducting layer 8 .

[0044] Other compositions and connection methods are the same as those in the second embodiment.

[0045] The single anti-heating layer is a single reflective film, and the graphene electric heating layer is a graphene electric heating film.

[0046] The one-way reflection film (5) reflects the radiant energy of the graphene electrothermal film back into the room.

[0047] The graphene electrothermal film (6), as a heating device, is laid on the bottom or around the heat preservation house, so that the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com