Water tank with anticorrosive and insulating performance for hanging garment steamer

A technology of anti-corrosion insulation and garment steamer, applied in anti-corrosion coatings, anti-fouling/underwater coatings, paints containing biocides, etc. It can solve problems such as hidden safety hazards and poor insulation performance of water tanks, and achieve corrosion inhibition and good insulation performance. , good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Provide the preparation method of the anticorrosion insulating coating of the water tank of the garment steamer with anticorrosion insulation performance of the present invention below, it comprises the following steps:

[0029] 1) Add the film-forming resin organic solvent into the reaction kettle, control the temperature at 50-70°C, and stir for 1-3h;

[0030] 2) Add silicon-acrylic emulsion, polyurea, glass fiber powder, pigment, nano-zirconia powder, nano-zinc oxide powder into the reaction kettle, control the temperature at 40-50°C; stir for 0.5-1.5h;

[0031] 3) Add bamboo fiber powder, eucalyptus oil, camphor oil, and methyl p-hydroxybenzoate to the reaction kettle, and control the temperature at 30-45°C; stir for 0.5-1h;

[0032] 4) Add auxiliary agent and curing agent into the reaction kettle, control the temperature at 30-40° C.; stir for 10-45 minutes to obtain anti-corrosion insulating coating.

[0033] The preparation method of the anti-corrosion insulatin...

Embodiment 1

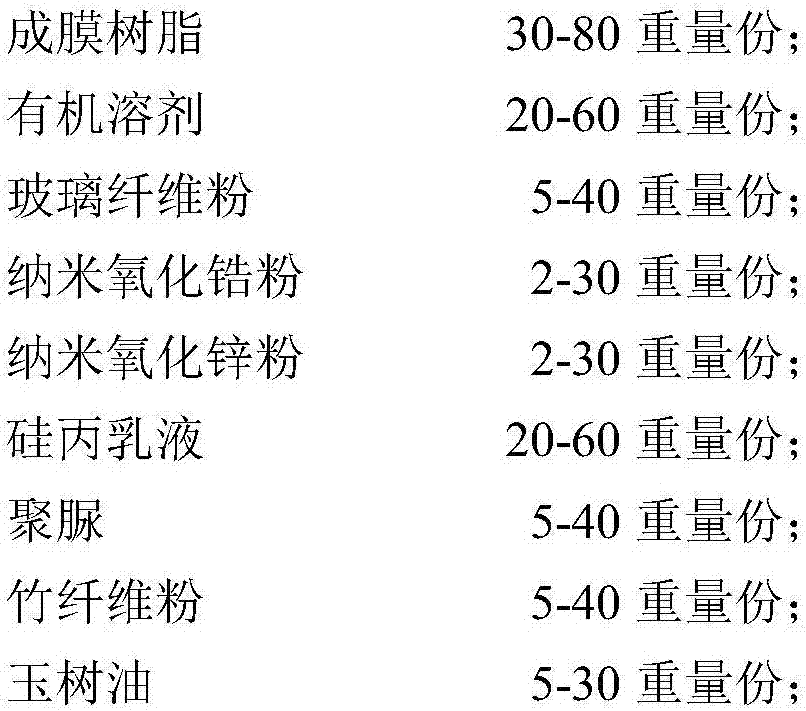

[0038] The anti-corrosion insulating coating includes the following raw materials in parts by weight:

[0039]

[0040] The film-forming resin is one or a mixture of epoxy resins, silicone resins, polyester acrylic resins, polyesterimide resins, and aldehyde and ketone resins. The organic solvent is one or more mixtures of varnish spirit, toluene, xylene and n-butanol. The pigment includes zinc chrome yellow, zinc powder, zinc phosphate, aluminum powder, micaceous iron oxide, zinc oxide, talcum powder, calcium carbonate, barium sulfate, mica powder and diatomaceous earth. The assistants include a mixture of one or more of film-forming assistants, corrosion inhibitors, dispersants, thermal stabilizers and thickeners. The thickener is propyltrimethyloxysilane. The curing agent is an epoxy resin curing agent. The bamboo fiber powder is nanometer or subnanometer fine powder obtained after bamboo fiber is ground.

Embodiment 2

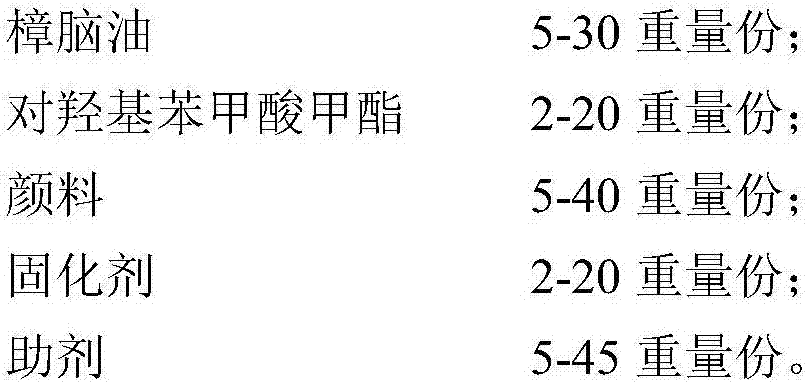

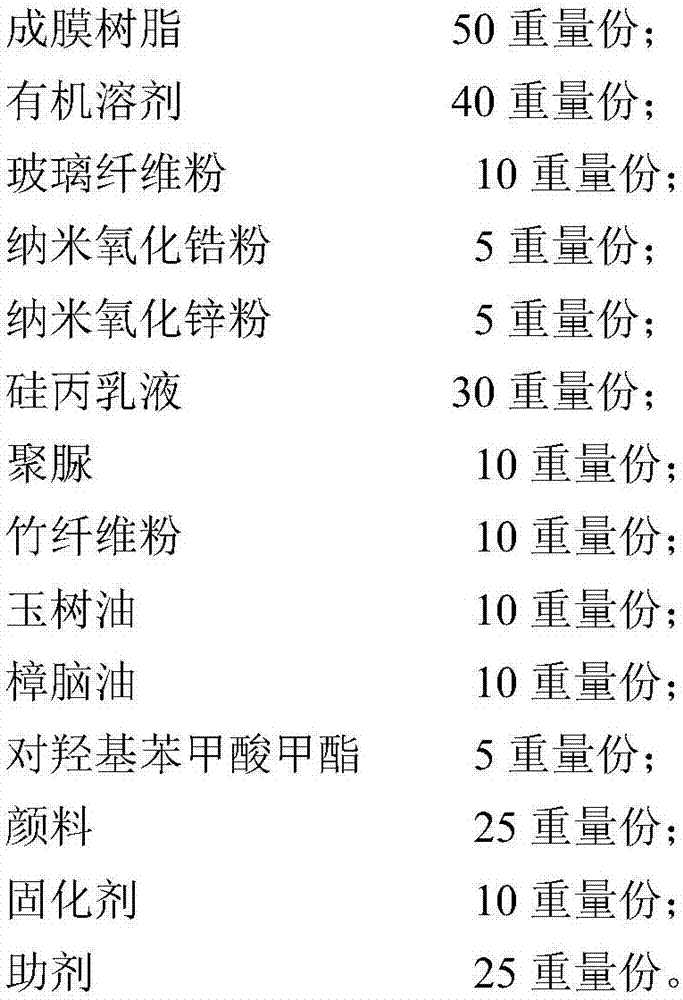

[0042] The anti-corrosion insulating coating includes the following raw materials in parts by weight:

[0043]

[0044] The film-forming resin is one or a mixture of epoxy resins, silicone resins, polyester acrylic resins, polyesterimide resins, and aldehyde and ketone resins. The organic solvent is one or more mixtures of varnish spirit, toluene, xylene and n-butanol. The pigment includes zinc chrome yellow, zinc powder, zinc phosphate, aluminum powder, micaceous iron oxide, zinc oxide, talcum powder, calcium carbonate, barium sulfate, mica powder and diatomaceous earth. The assistants include a mixture of one or more of film-forming assistants, corrosion inhibitors, dispersants, thermal stabilizers and thickeners. The thickener is propyltrimethyloxysilane. The curing agent is an epoxy resin curing agent. The bamboo fiber powder is nanometer or subnanometer fine powder obtained after bamboo fiber is ground.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com