Liquid crystal polyacrylate-liquid crystal polyurethane interpenetrating network liquid crystal elastomer

A technology of polyacrylate and liquid crystal elastomer, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve problems such as insufficient stress, and achieve the effects of excellent reversible deformation, excellent strain performance, and excellent strain capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

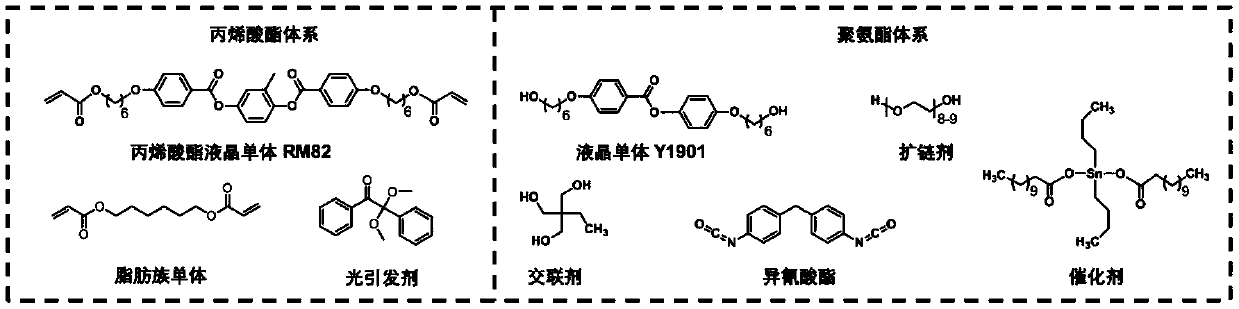

[0046] Embodiment 1: The specific preparation steps of liquid crystal polyacrylate / liquid crystal polyurethane interpenetrating network liquid crystal elastomer are as follows:

[0047] Weigh liquid crystal acrylate monomer RM82 (0.672g, 1mmol), aliphatic acrylate monomer HODA (0.023g, 0.1mmol), photoinitiator-benzoin dimethyl ether DMPA (0.003g, 0.011mmol), polyurethane liquid crystal monomer Body Y1901 (0.43g, 1mmol), polyethylene glycol PEG400 (0.268g, 0.67mmol), 4,4-methylene diisocyanate phenyl MDI (0.445g, 1.78mmol), trimethylolpropane TMP (0.008g, 0.06mmol) and dibutyltin dilaurate DBTL (0.021g, 0.03). After water removal treatment, 35 mL of anhydrous N,N-dimethylformamide was added. Under the condition of blowing nitrogen, react at 70-80°C for 4.5h. After the reaction is over, about 90% of the solvent is removed, and after waiting for the system to become viscous, at 6.9mW.cm -2 Under 365nm ultraviolet irradiation (10-20s), quickly inject it into the polytetrafluoro...

Embodiment 2

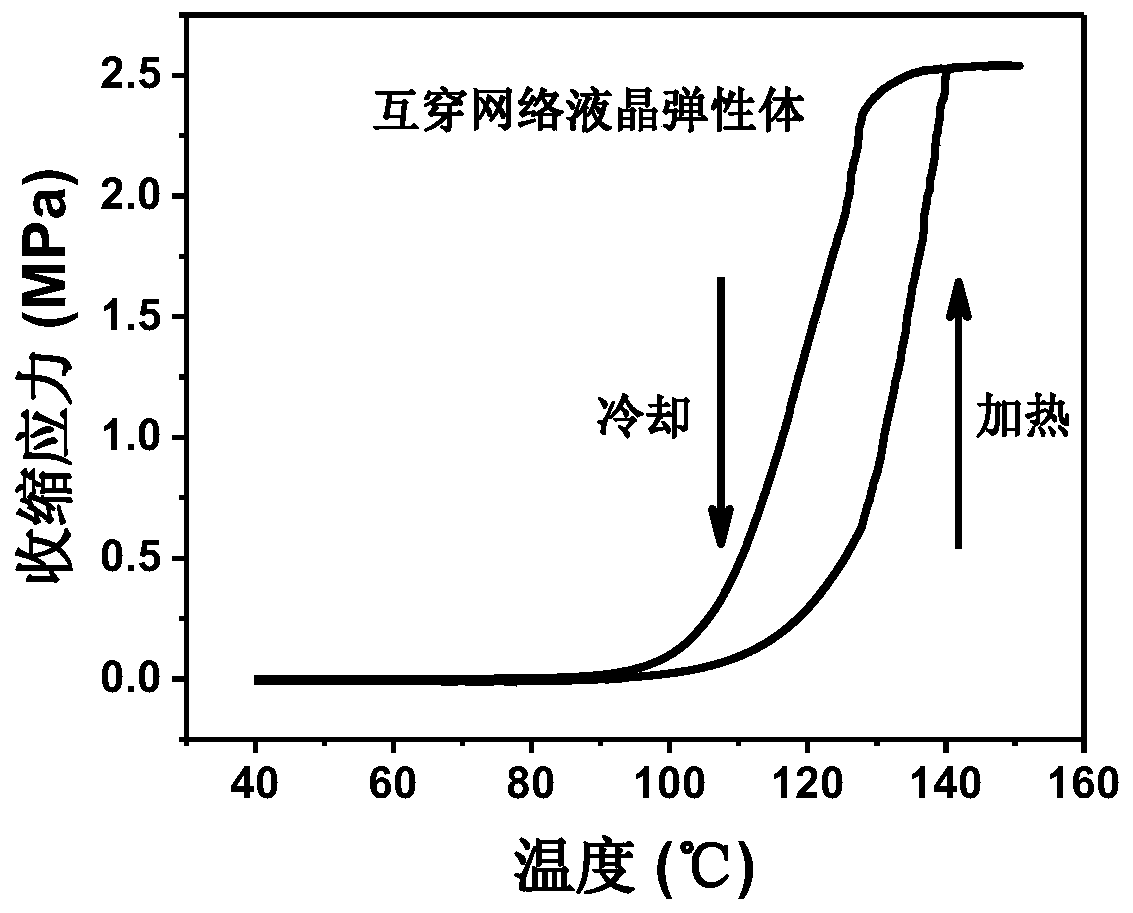

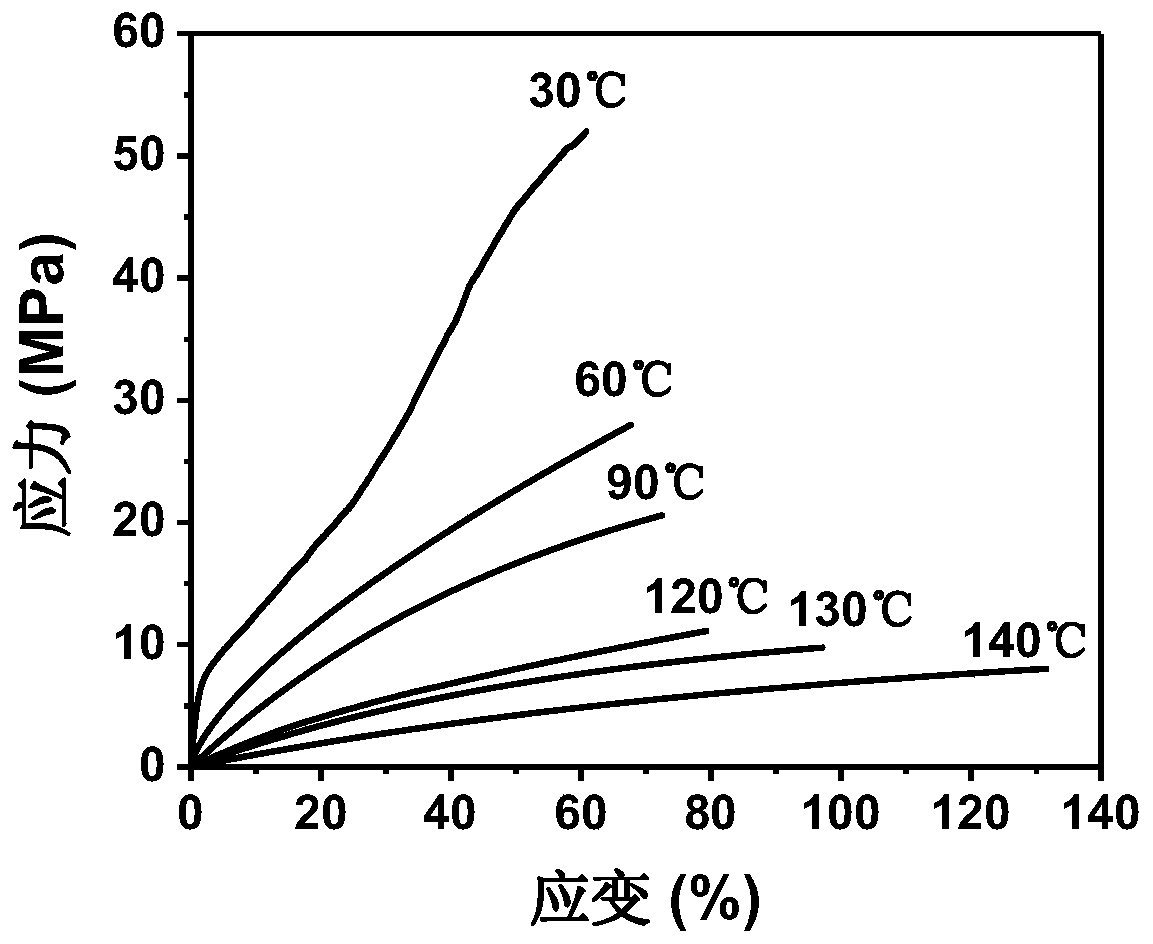

[0048] Example 2: The prepared liquid crystal polyacrylate / liquid crystal polyurethane interpenetrating network liquid crystal elastomer at different temperatures stress-strain, deformation, strain under the maximum load state, shrinkage force and load-bearing capacity test during the heating process;

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com