Self-contained conditioning abrasive article

a self-contained, abrasive technology, applied in the direction of abrasive surface conditioning devices, manufacturing tools, other chemical processes, etc., can solve the problems of dullness and wear of abrasive grits, and achieve the effect of increasing the removal rate and avoiding the drop in the removal ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

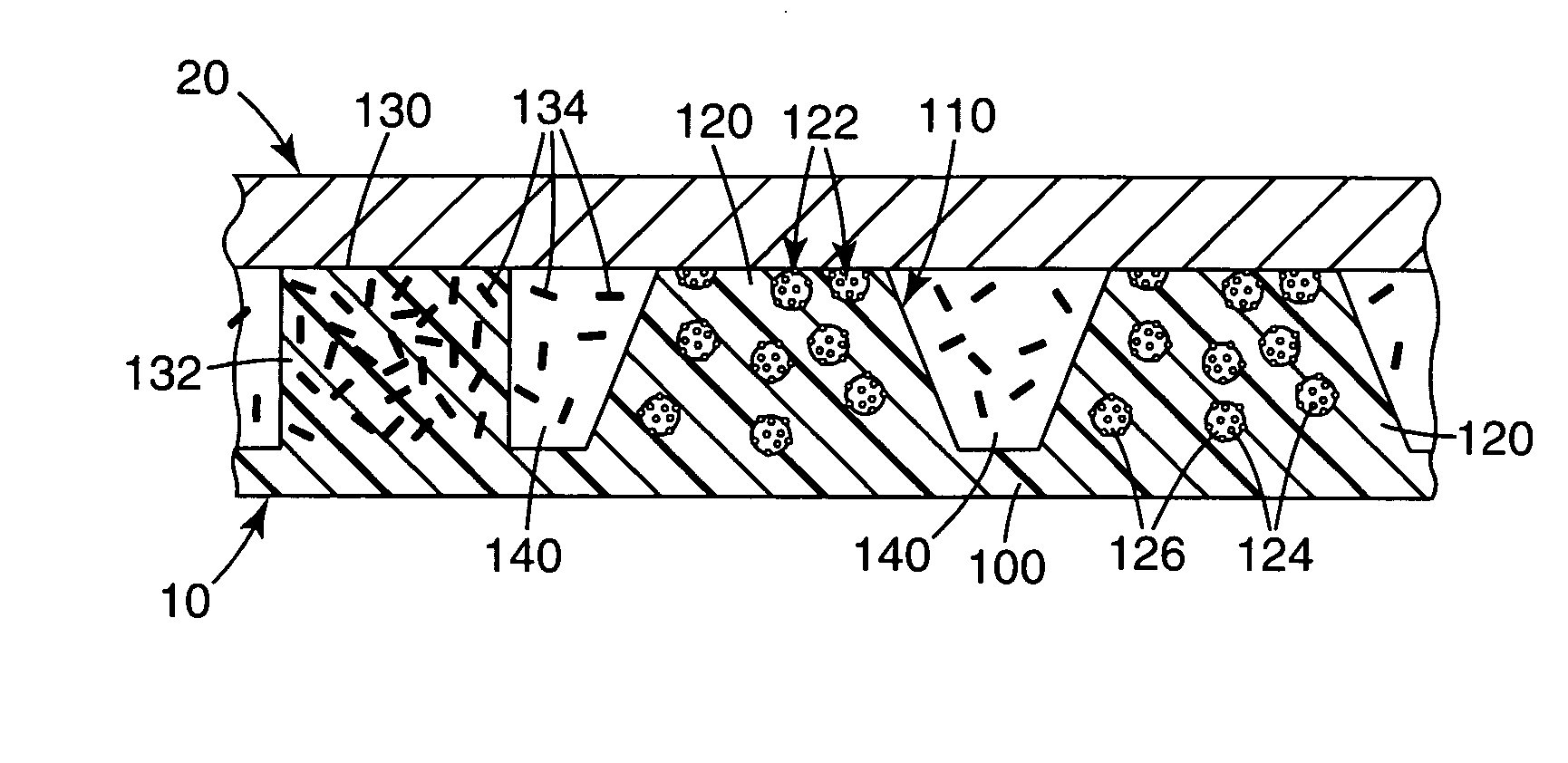

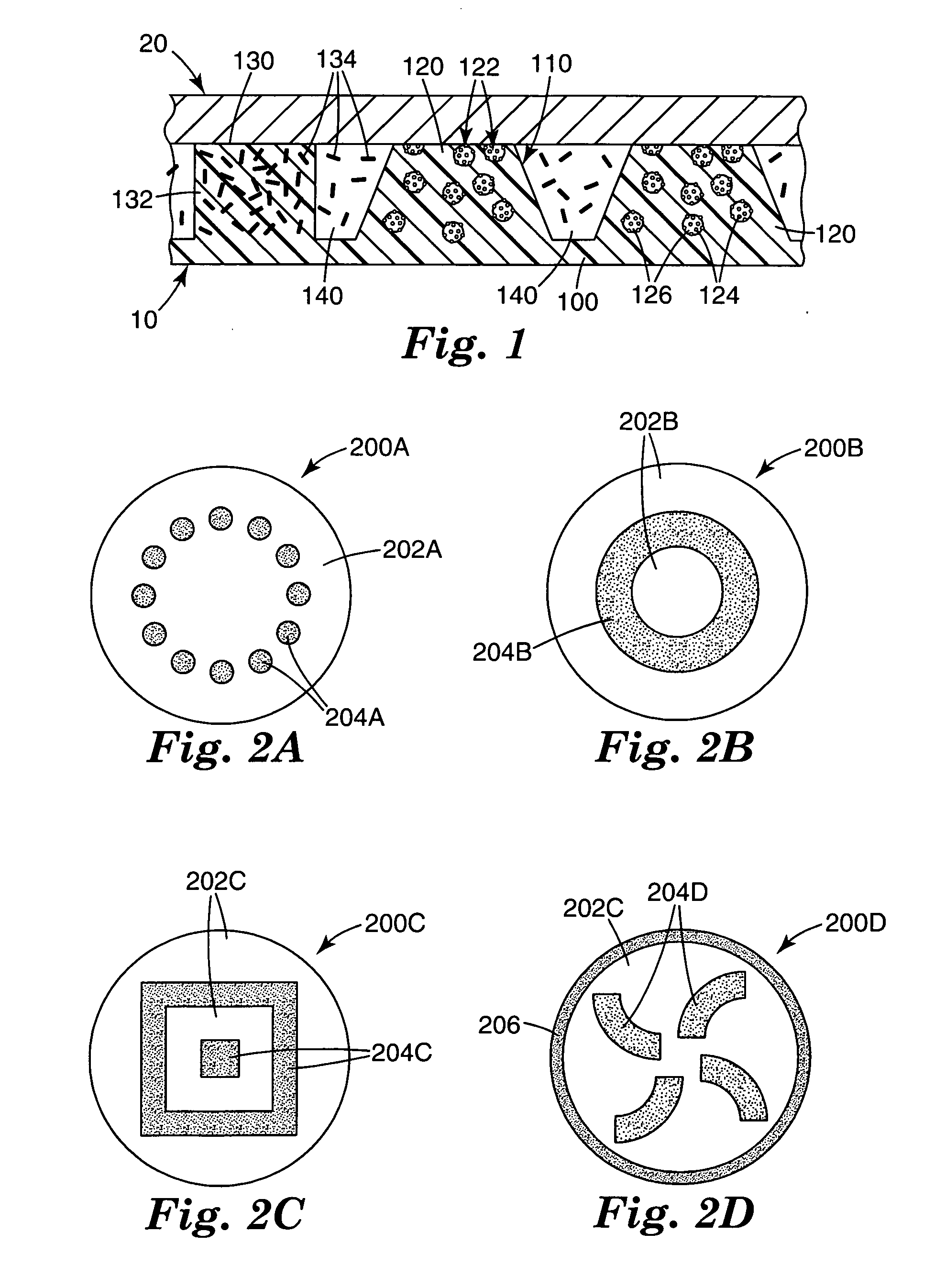

[0060] A fixed abrasive article was prepared by inserting eight 5-cm diameter circular regions of planar conditioning amalgam segments prepared by Method III into a 30.5 cm (12 in.) disk of a fixed abrasive article prepared by Method I. The eight disks were evenly spaced around the perimeter approximately 3.8 cm (1.5 in.) from the edge.

example 2

[0061] A fixed abrasive article was prepared by inserting eight 5-cm diameter circular regions of textured conditioning amalgam segments prepared by Method II into a 30.5 cm (12 in.) disk of a fixed abrasive article prepared by Method I. The eight disks were spaced as in Example 1.

example 3

[0062] A fixed abrasive article was prepared by cutting a 30.5 cm (12 in.) disk from a sheet having alternating stripes of the fixed abrasive article prepared by Method I and the textured conditioning amalgam segment prepared by Method II. The stripes of fixed abrasive article were 5 cm (2 in.) wide and the stripes of textured conditioning amalgam were 2.54 cm (1 in.) wide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com