Two-stage series connection noise reduction structure and extractor hood with same

A noise reduction, fan technology, applied in the fields of oil fume removal, household heating, lighting and heating equipment, etc., can solve the problems of performance degradation, large internal resistance loss of fan system, and increased noise, etc., to reduce disturbance, increase flow, Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

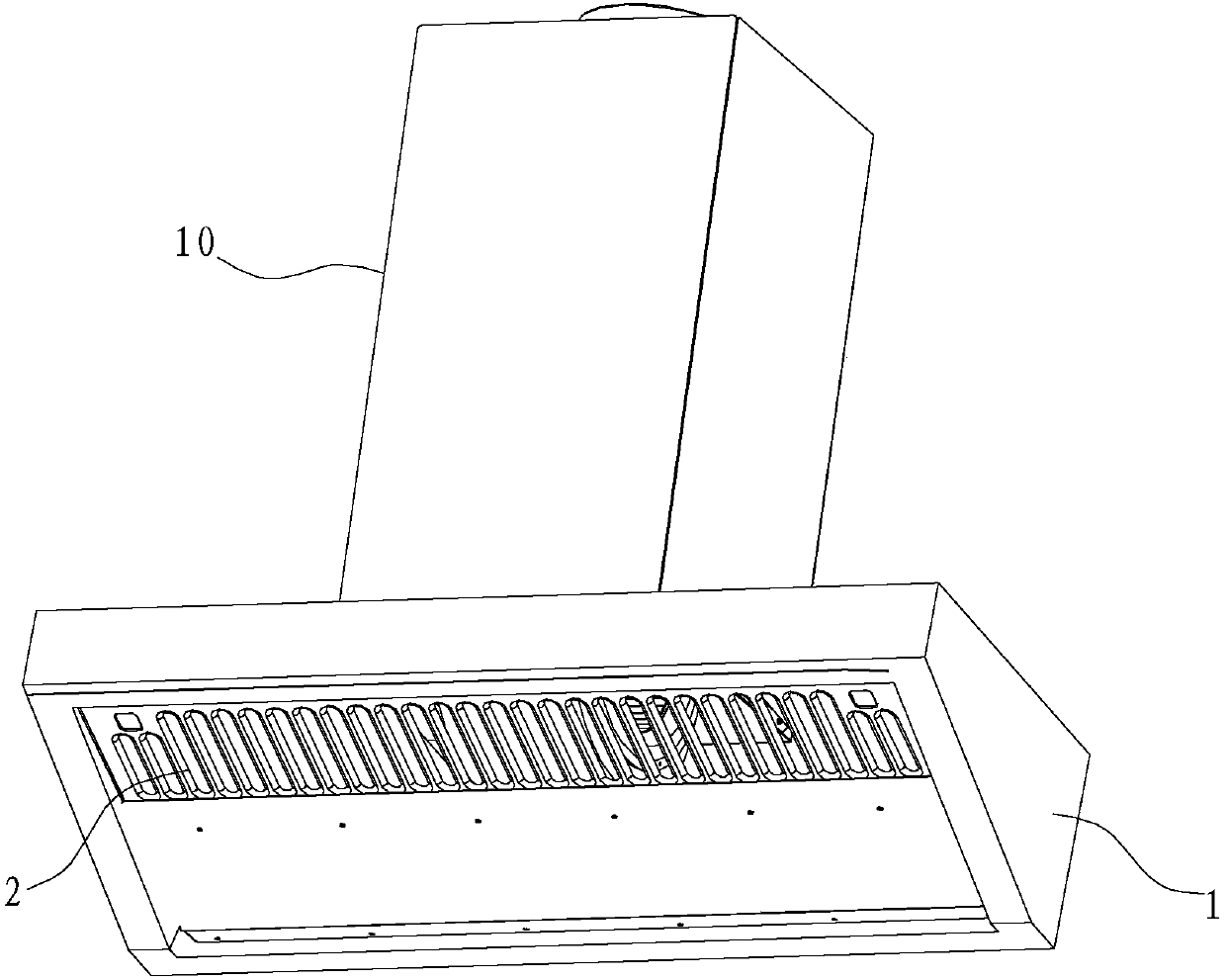

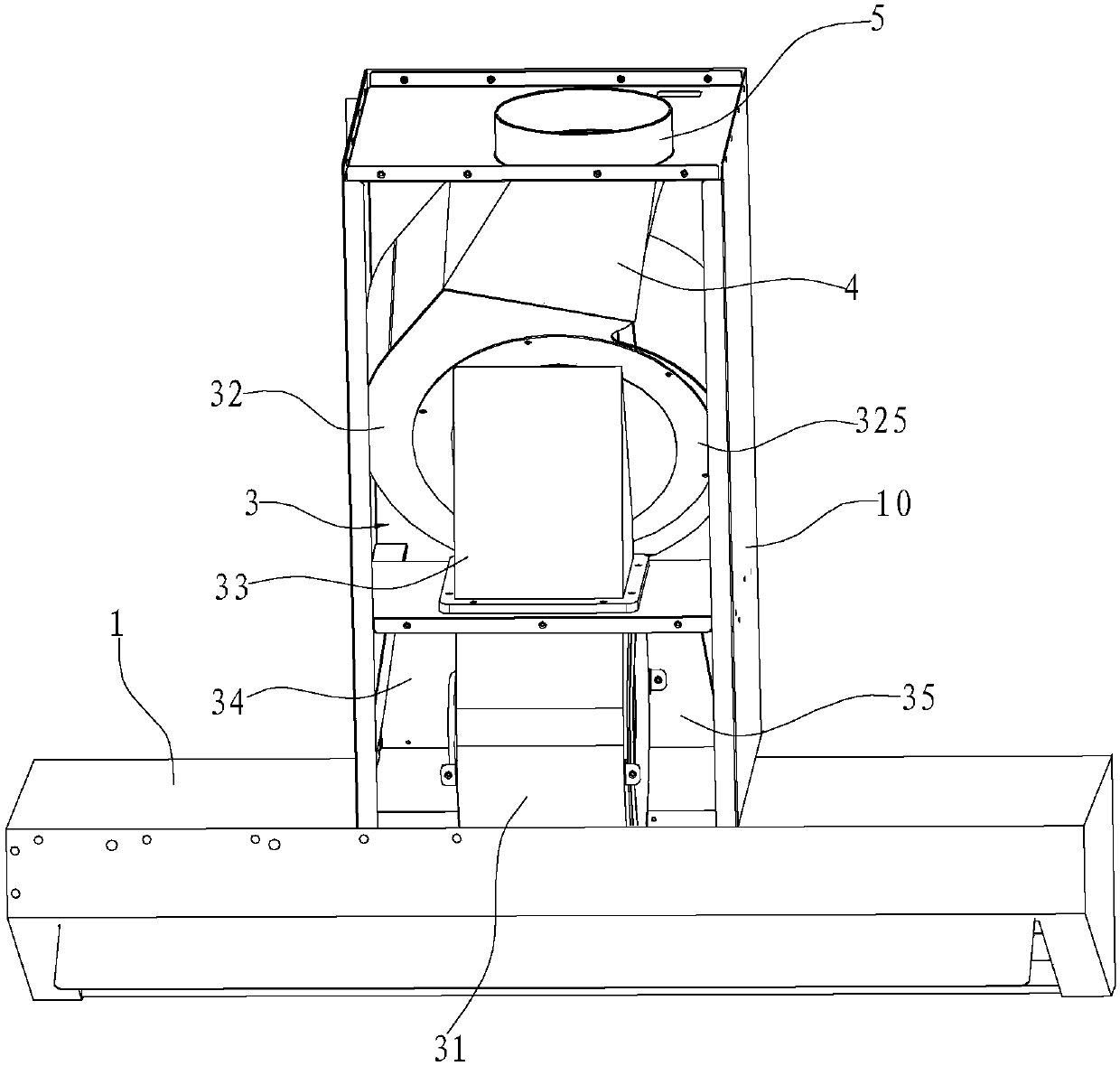

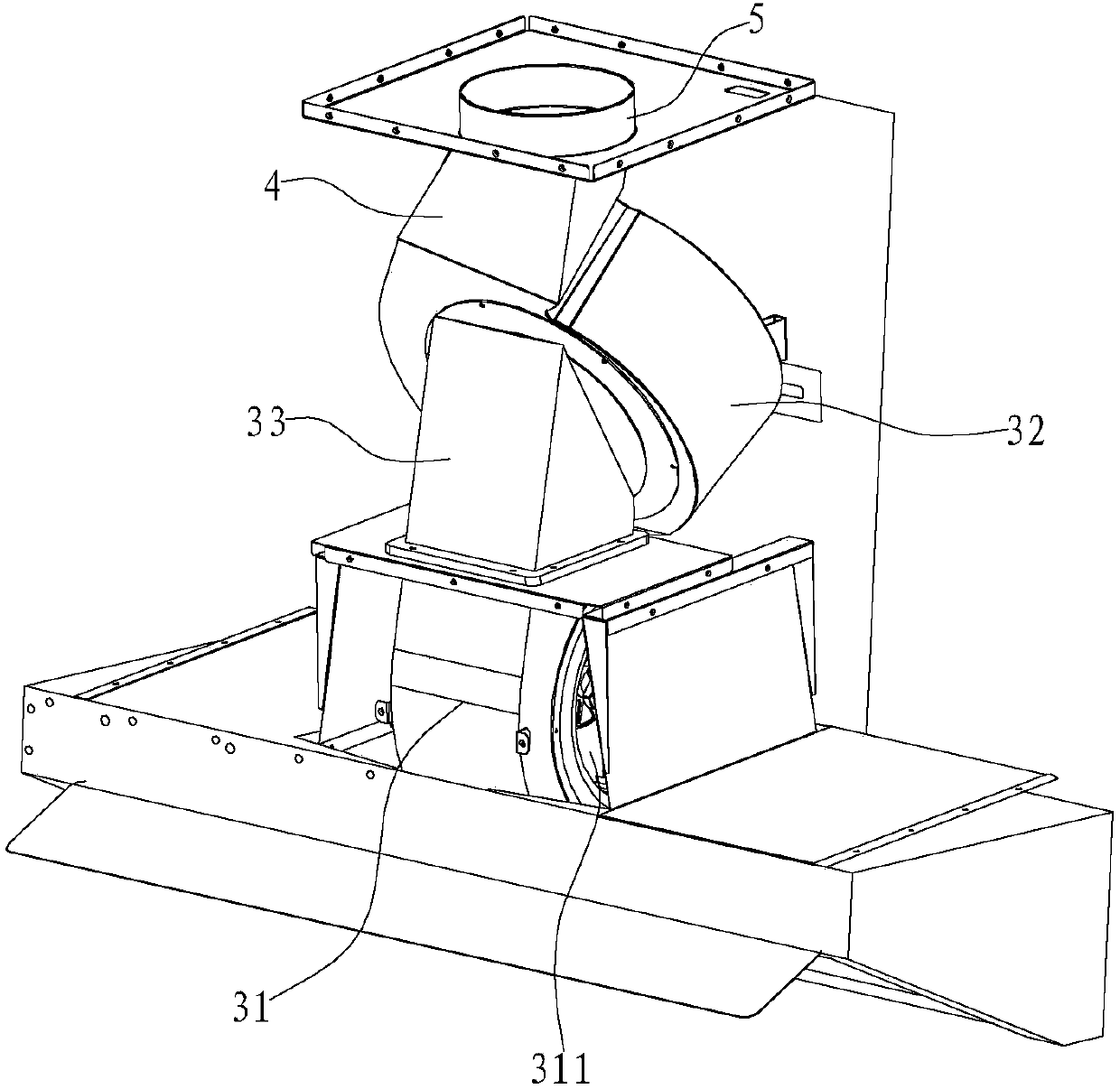

[0020] Such as Figure 1-7 As shown, a range hood includes a fume collecting hood 1 and a casing 10 arranged above the fume collecting hood 1. The casing 10 is respectively provided with a fan system 3, and the fan system 3 includes a primary fan 31 and a secondary fan 31. fan 32, and the secondary fan 32 is arranged above the primary fan 31. The primary fan 31 and the secondary fan 32 are both centrifugal fans, wherein the secondary fan 32 is arranged obliquely forward, with its air inlet 321 facing forward, and the primary fan 31 is a double-inlet centrifugal fan, and the primary fan 31 is vertically arranged , and its air inlet 311 faces the left and right directions, and forms air inlet gaps 34, 35 with the left and right side plates of the casing 10, respectively. The air outlet 312 of the primary fan 31 is communicated with the air inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com