Initial processing device for optical glass

A preliminary processing and optical glass technology, applied in the direction of glass cutting device, glass production, glass manufacturing equipment, etc., can solve the problems that affect the industrial production efficiency and cannot form automatic speed, so as to quickly reduce the glass temperature, facilitate the overall transfer, The effect of reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

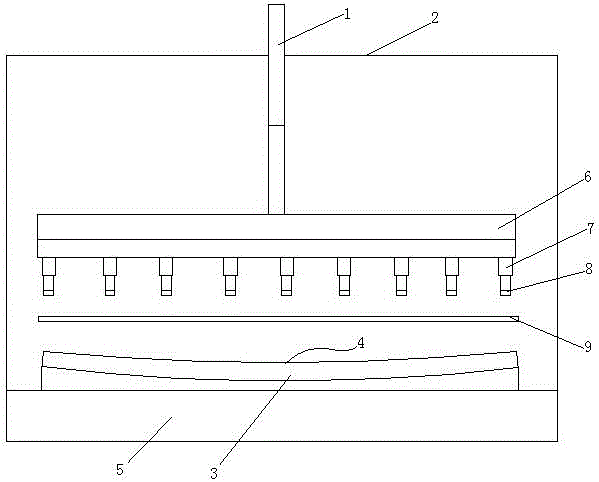

[0023] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0024] like figure 1 As shown, a preliminary processing device for optical glass includes: a stud plate 6 arranged oppositely and a deformation plate with a curved surface 4, which is characterized in that several studs are arranged on one side of the stud plate 6 7. The studs 7 are vertically threaded on the stud plate 6. The side of the deformation plate with the arc-shaped surface 4 is opposite to the side of the stud plate 6 with the studs 7. Each stud 7 can pass through the Thread rotation adjusts the length of the stud plate 6, the side of the stud 7 bar without the stud 7 is connected to the driving arm 1, the driving arm 1 can drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com