Wafer transferring equipment

A technology for conveying equipment and wafers, applied to lighting and heating equipment, conveyor objects, furnaces, etc., can solve problems such as unfavorable production efficiency, repeated investment and waste of space equipment, and increased wafer fragments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

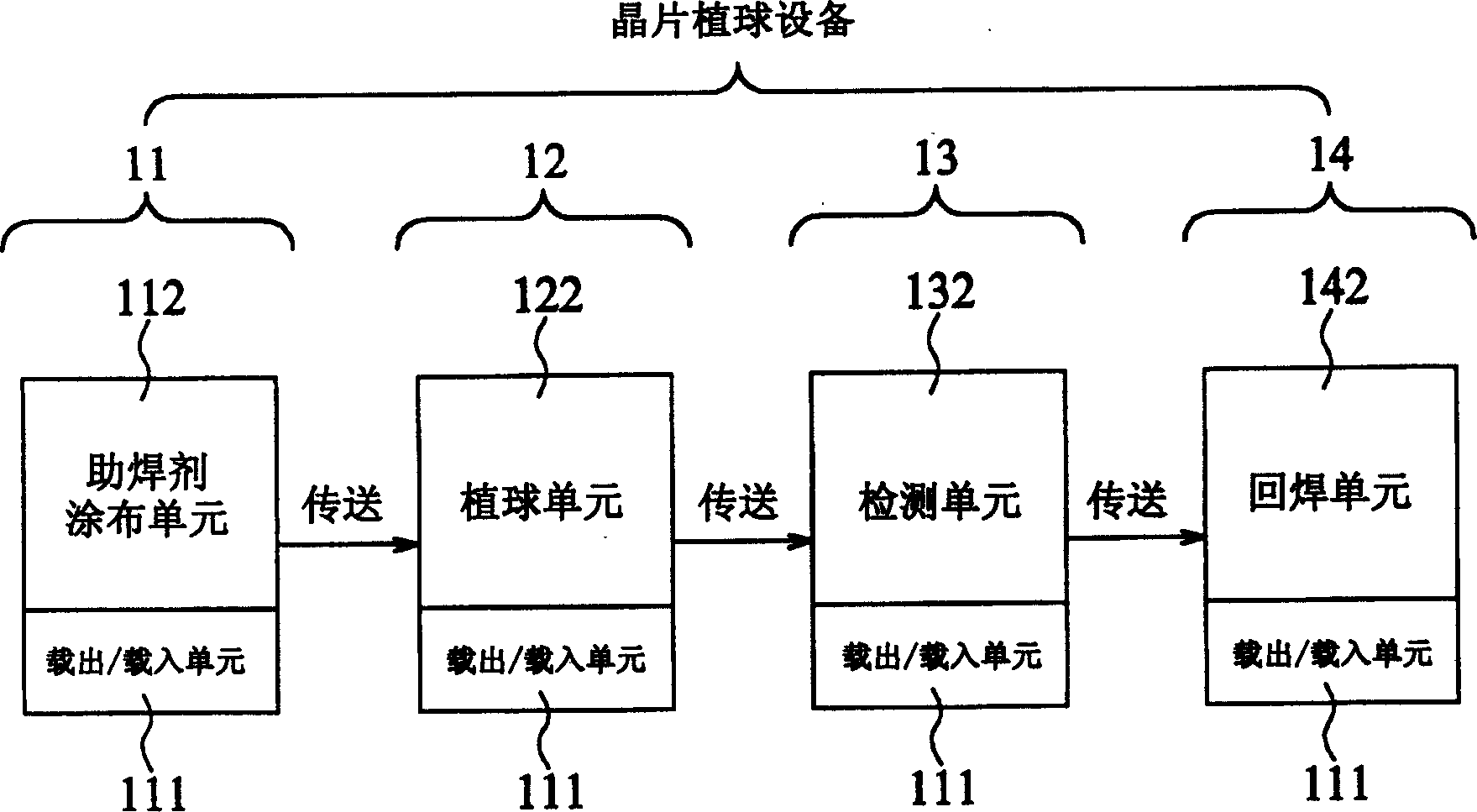

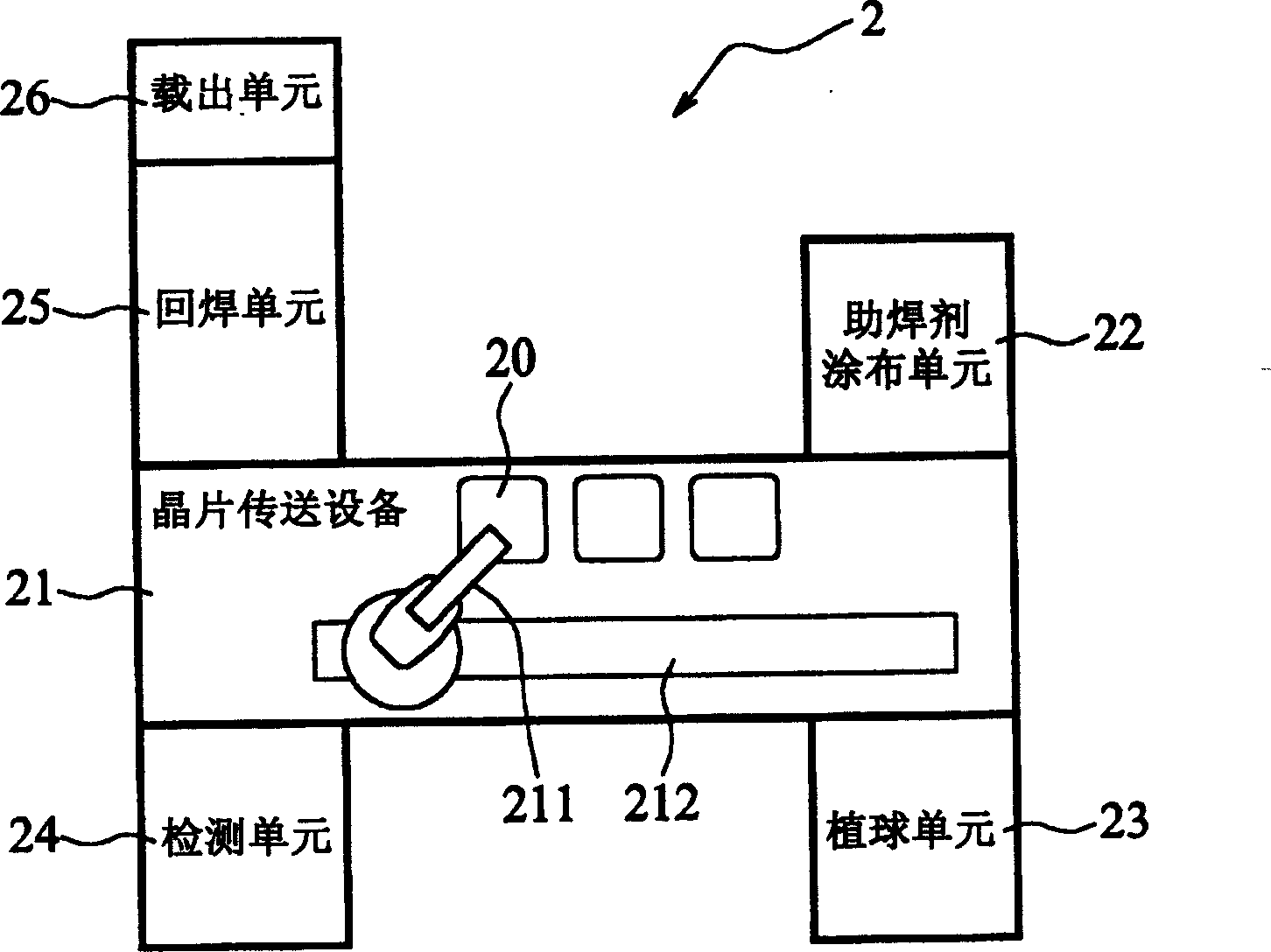

[0029] refer to figure 2 , a first embodiment of a wafer transfer apparatus of the present invention will be described. like figure 2 As shown, the wafer transfer equipment 21 is used to include: at least one crystal boat box 20, a flux coating unit 22, a ball planting unit 23, a detection unit 24, a reflow unit 25, and a load-out unit 26 Wafer ball placement equipment 2. The wafer transfer device 21 further includes a robot arm 211 and a stage 212 .

[0030] The at least one boat box 20 is used to carry one or more wafers. The at least one wafer pod 20 is loaded into the wafer transfer device 21 . By the mechanical arm 211 of the wafer transfer device 21, a wafer is taken out from the at least one wafer box 20, and sent to the flux coating unit 22, where after flux coating is completed, the The robot arm 211 transfers the wafer to the ball planting unit 23 , and after the ball planting is completed, the robot arm 211 still uses the robot arm 211 to transfer the wafer t...

no. 2 example

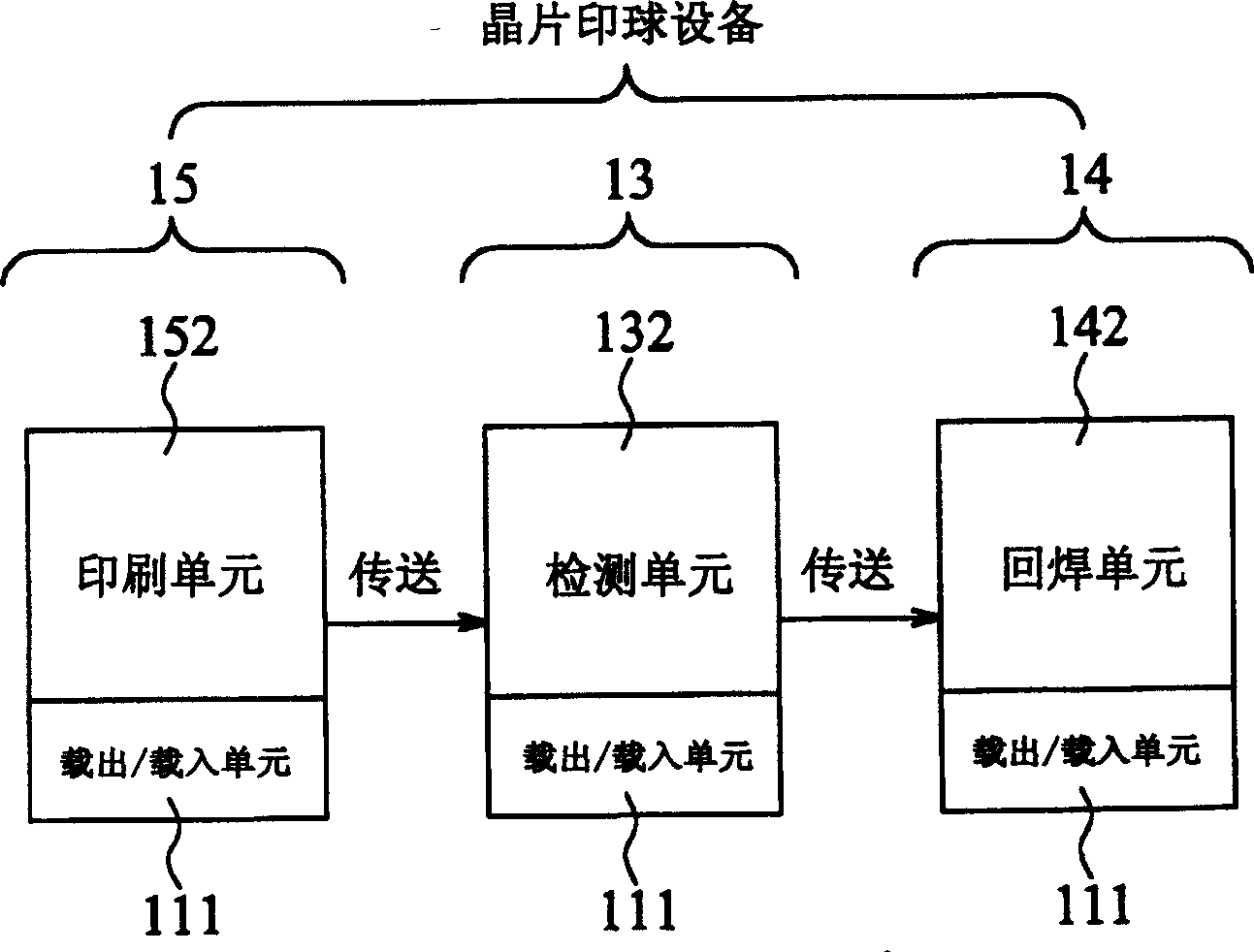

[0033] refer to image 3 , a second embodiment of a wafer transfer apparatus of the present invention is described. like image 3 As shown, the wafer transfer equipment 21 is used in the wafer ball planting equipment 3 including at least one wafer boat box 20 , a printing unit 32 , a testing unit 24 , a reflow unit 25 , and a loading unit 26 . The wafer transfer device 21 further includes a robot arm 211 and a stage 212 .

[0034] The at least one boat box 20 is used to carry one or more wafers. The at least one wafer pod 20 is loaded into the wafer transfer device 21 . By the robotic arm 211 of the wafer transfer device 21, a wafer is taken out from the at least one crystal boat box 20, and sent to the printing unit 32, where after the solder paste printing is completed, the robotic arm 211 will still The wafer is transferred to the inspection unit 24 . At this time, when the inspection unit 24 determines that it is a good product, the chip is sent to the reflow unit 25 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com