Back structure of electron multiplying charge-coupled device (EMCCD) and production method of back structure

A charge-coupled device and backside structure technology, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of less device solutions, chip cracking, high cost, etc., and achieve improved light response time, uniform and effective removal, and reduced stress The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

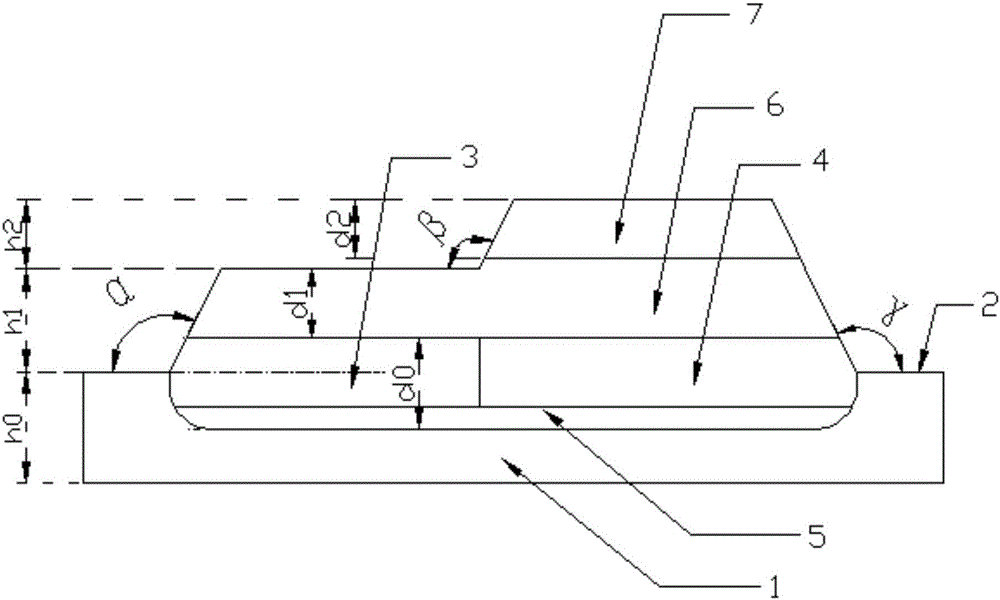

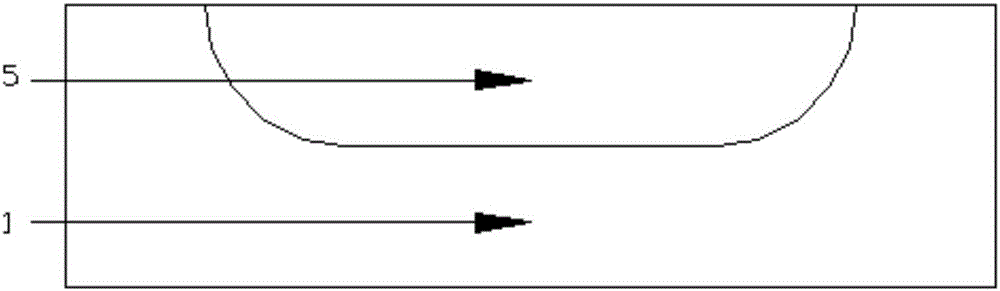

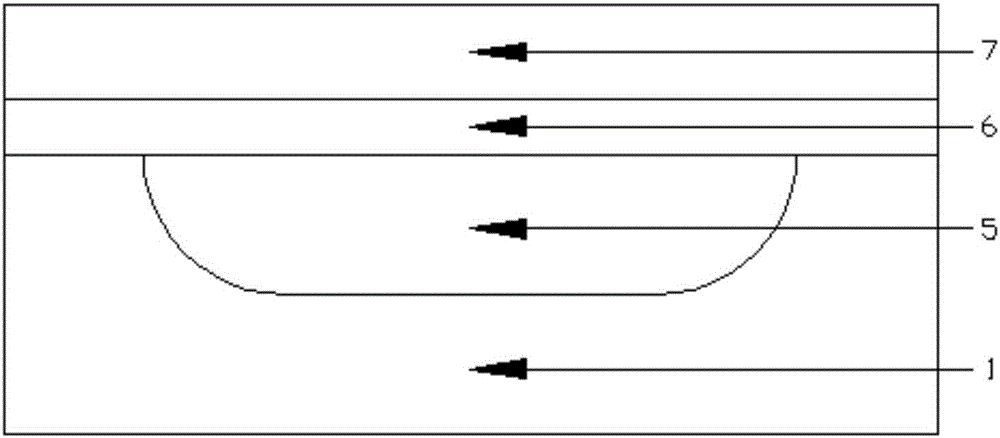

[0034] Such as figure 1 Shown in the structure schematic diagram of the present invention: a kind of EMCCD chip back structure comprises EMCCD chip 1, electrode lead-out area 2 of EMCCD chip 1, photosensitive area 3, storage gain area 4, ion implantation area 5, anti-reflection film 6 and metal shielding layer 7. Electrode extraction region 2, photosensitive region 3 and storage gain region 4 are adjacently formed in the backside silicon body of EMCCD chip 1, ion implantation region 5 is formed in photosensitive region 3 and storage gain region 4 by low-energy ion implantation, and in photosensitive region 3 An anti-reflection film 6 is coated on the surface, and an anti-reflection film 6 and a metal shielding layer 7 are provided on the surface of the storage gain area 4 .

[0035] The electrode lead-out area 2 is arranged on both sides of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com