Stackable packaging box

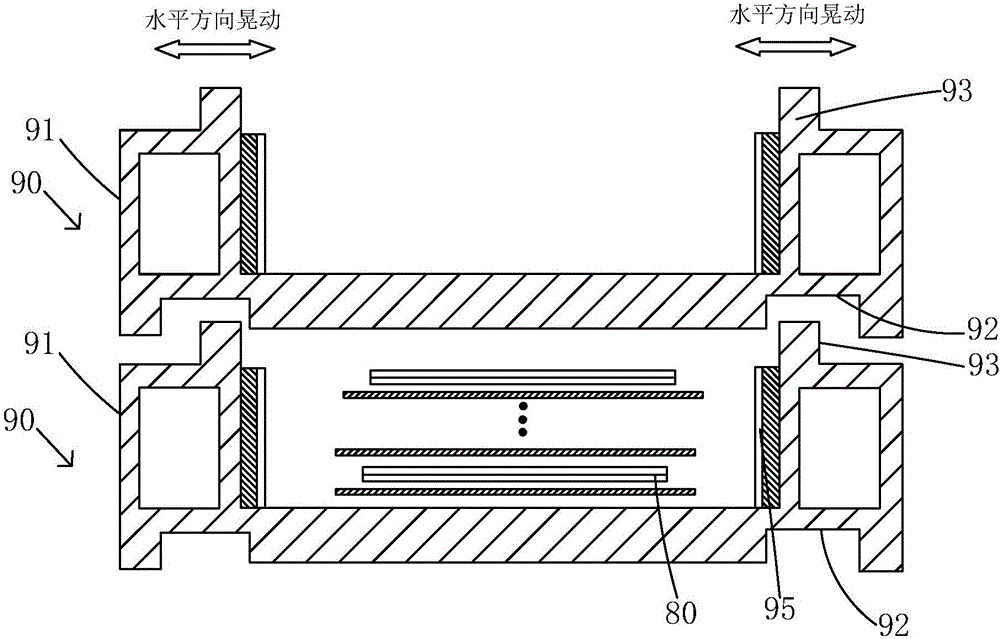

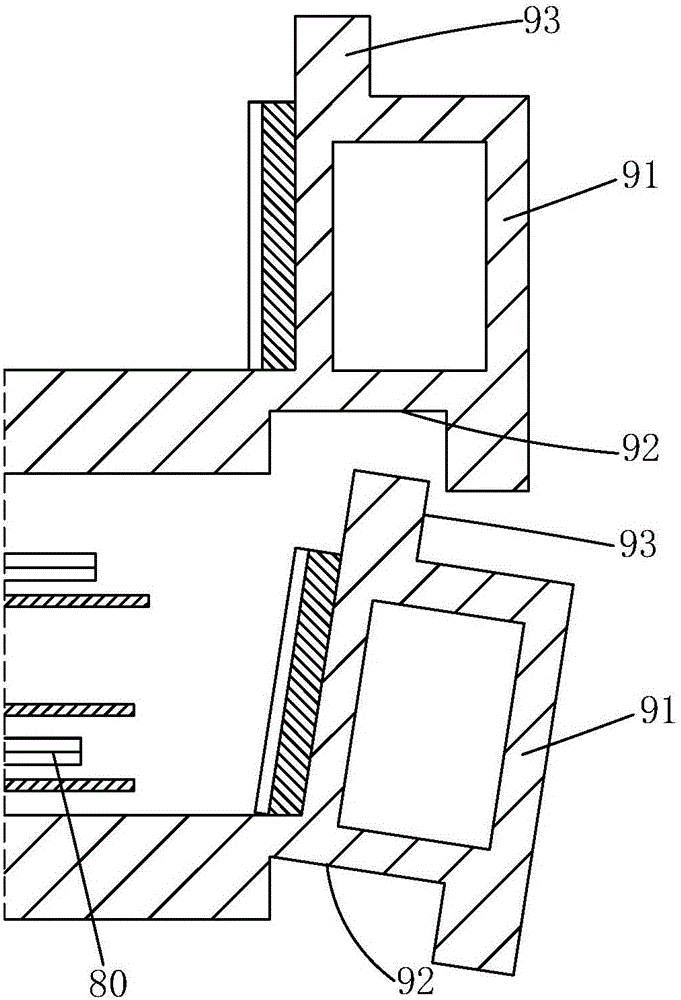

A technology for packaging boxes and boxes, which is applied in the directions of packaging, transportation and packaging, and packaging of fragile items, etc., can solve the problems of breakage of the liquid crystal panel 80, low friction, deformation and eversion of the side walls, etc., and reduce the possibility of fragmentation. , Prevent horizontal shaking, reduce the effect of sidewall eversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

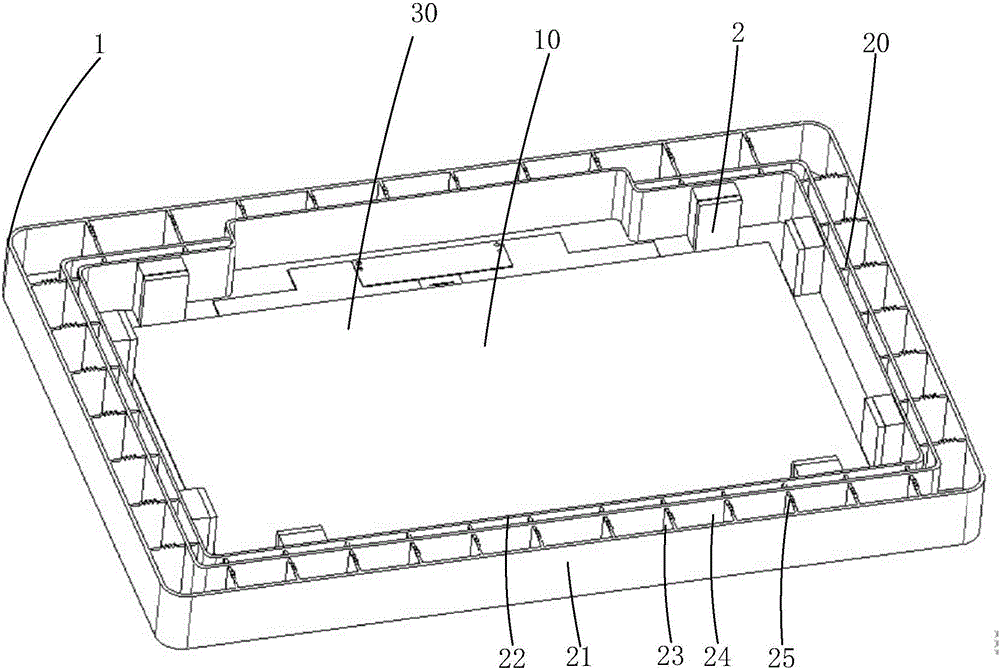

[0036] see Figure 3 to Figure 7 , the present invention provides a stackable packaging box for packaging liquid crystal panels, comprising a box body 1 made of plastic material with an opening on the top surface, and several buffer baffles located in the box body 1 for buffering the liquid crystal panel 2.

[0037] Specifically, the box body 1 includes a bottom plate 10 and a side wall 20 vertically connected to the bottom plate 10 , the bottom plate 10 and the side wall 20 together define a receiving groove 30 for accommodating a liquid crystal panel.

[0038] Specifically, the plurality of buffer baffles 2 are fixed on the inner side of the side wall 20, and the buffer baffles 2 are made of elastic materials. Specifically, as Figure 5-6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com