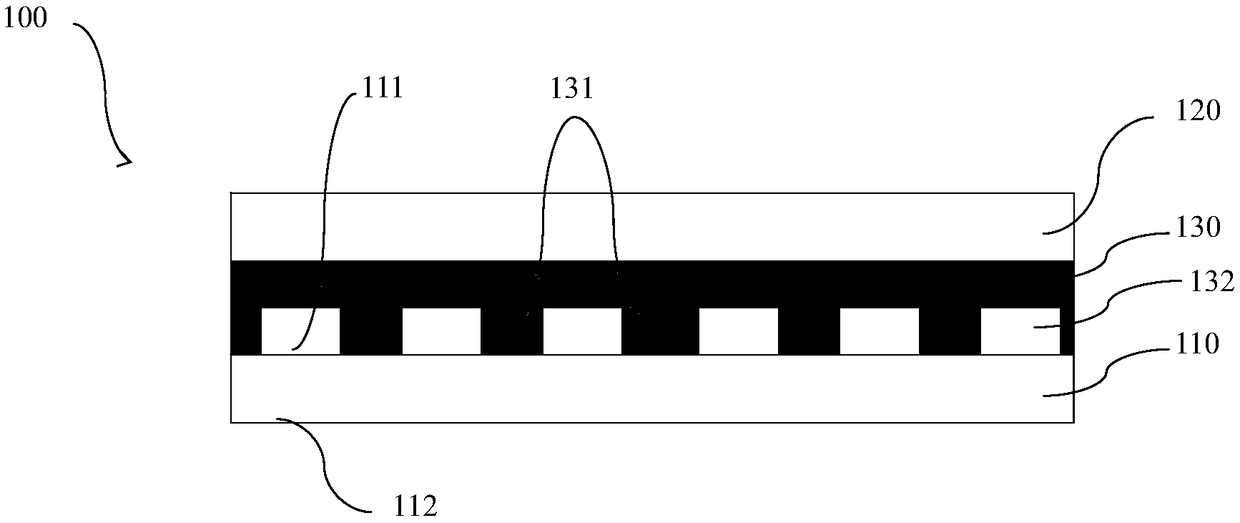

Cover plate and manufacturing method thereof, flexible display module and electronic equipment

A technology for flexible display and electronic equipment, which is applied to the input/output process of electrical digital data processing, instruments, data processing, etc. Fragmentation constraints and other issues, to achieve the effect of improving shear resistance, improving chipping resistance, and reducing the probability of substrate chipping

- Summary

- Abstract

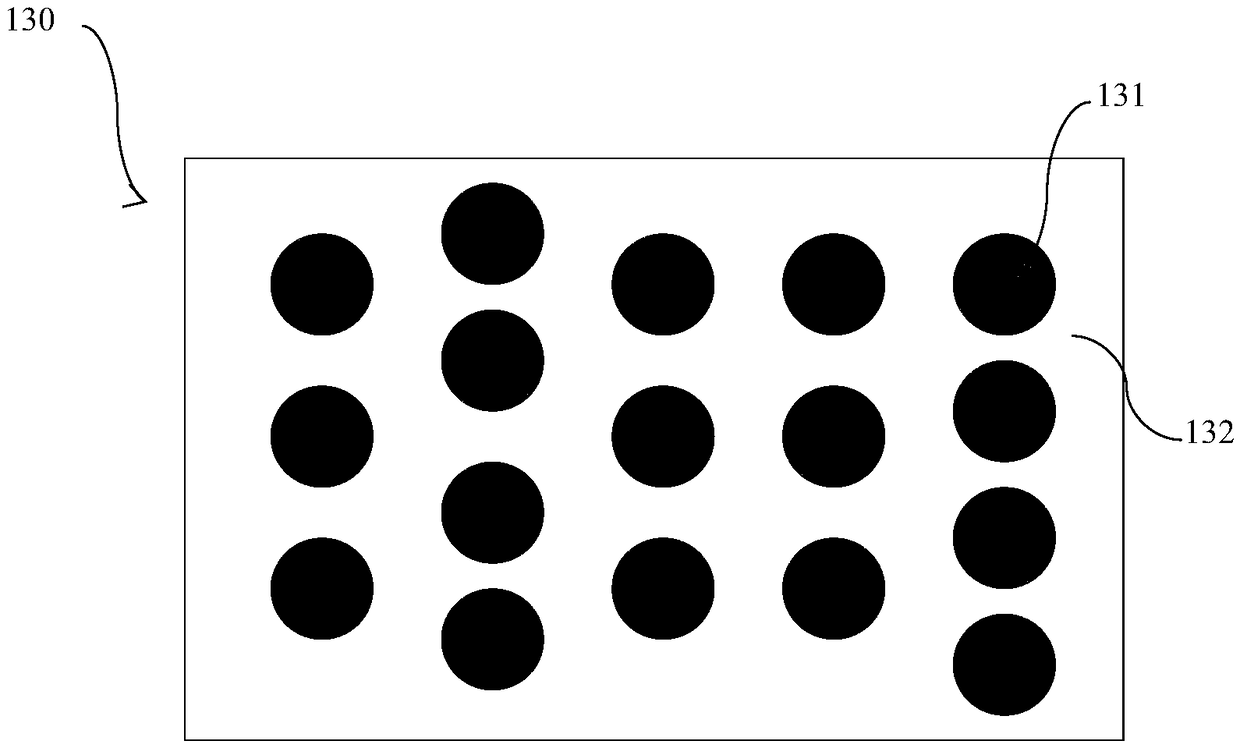

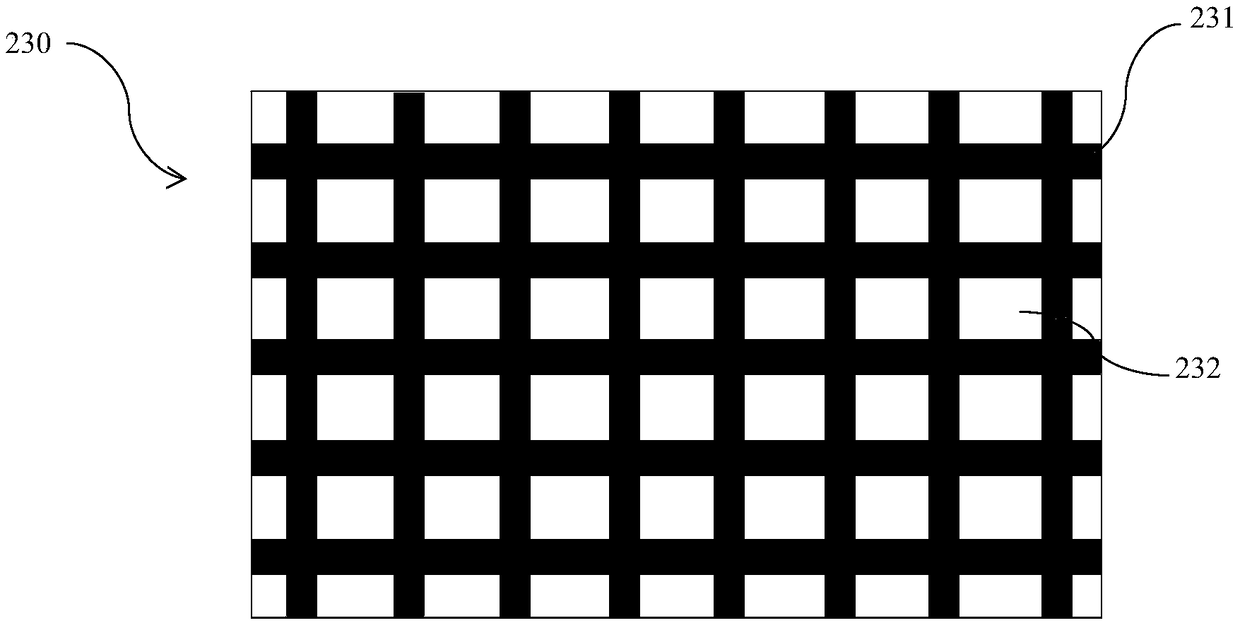

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ,510

[0058] According to an embodiment of the present invention, 510 includes:

[0059] making a mold for forming the first adhesive layer having the first protrusion;

[0060] Use the mold to make the first adhesive layer.

[0061] In this embodiment, the mold may refer to a molding tool capable of molding the first adhesive layer by means of injection molding or extrusion. The mold can be made of metal, or other high temperature resistant materials. The way to make the mold can be casting or machining. The first adhesive layer produced by the mold may be the final first adhesive layer, or a semi-finished product of the first adhesive layer, which needs to be processed in other ways to be finally shaped. According to the manufacturing method of the cover plate in this embodiment, the first adhesive layer can be manufactured efficiently and quickly by using a mold, while ensuring the stability of the shape and structure of the first adhesive layer.

[0062]According to an embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com