Polaroid stripping machine and method for stripping polaroid

A polarizer and peeling machine technology, applied in chemical instruments and methods, optics, nonlinear optics, etc., can solve the problems of high static electricity, low efficiency, safety and health hazards of circuits and operators, and achieve the effect of eliminating static electricity accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

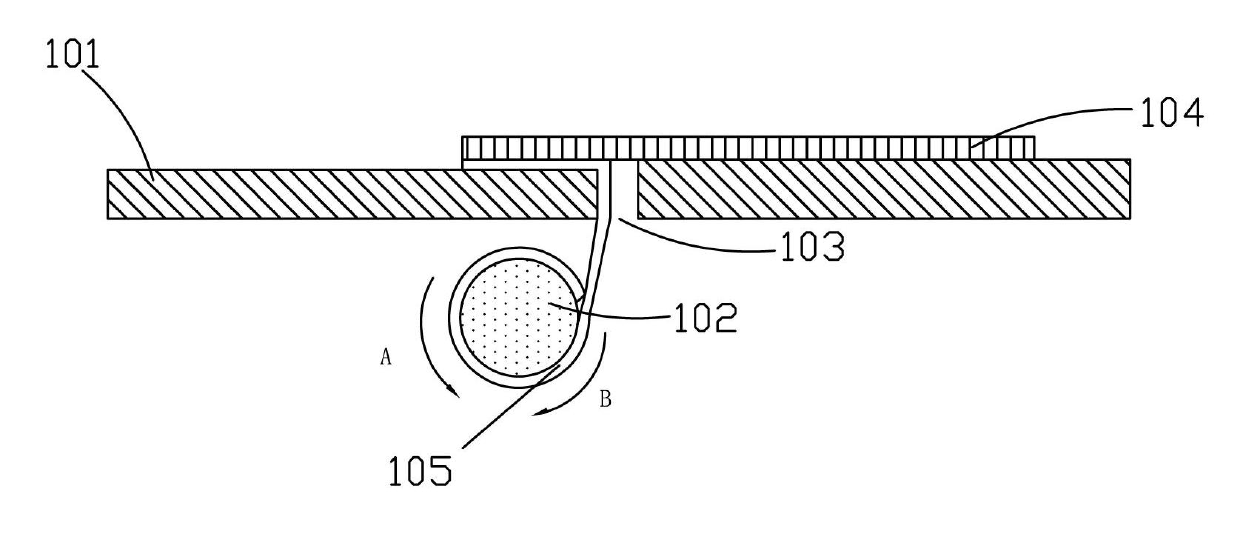

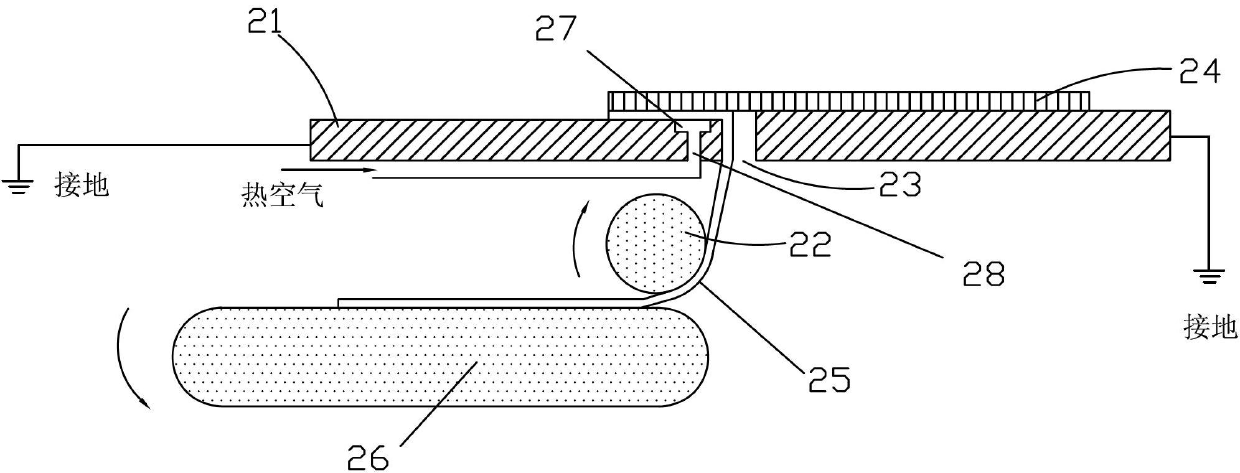

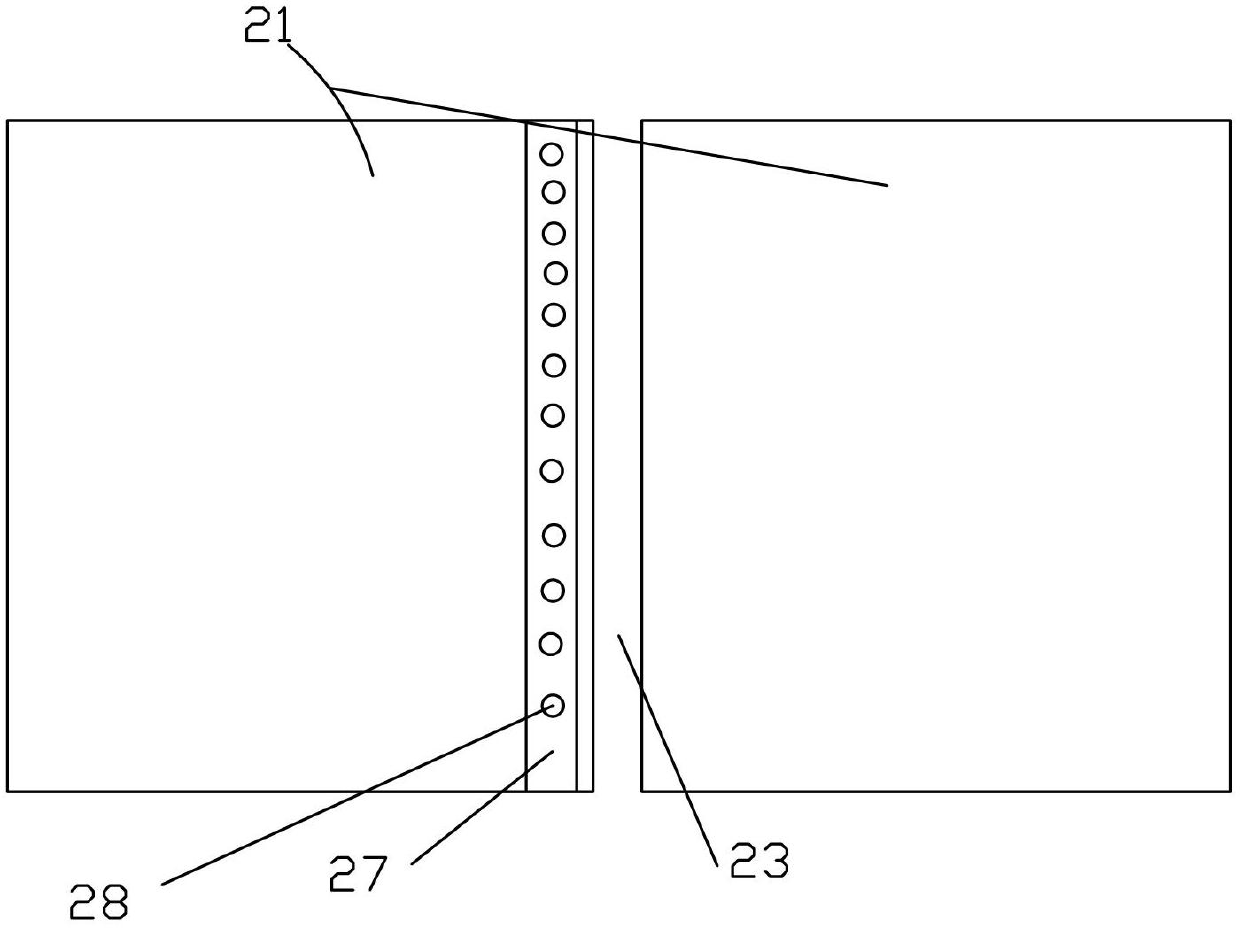

[0030] see figure 2 and image 3 , figure 2 It is a schematic diagram of the longitudinal section structure of a preferred embodiment of the polarizer peeling machine of the present invention, image 3 for figure 2 top view. The polarizer peeling machine of this preferred embodiment comprises an operating platform 21 and a conveyor strip 26 with a translatable surface. The operating platform 21 is provided with a slit 23 as a polarizer stripping position. The strip conveyor belt 26 can The translational surface is located below the slit 23; when the polarizer 25 is peeled off, the glass substrate 24 to be stripped of the polarizer slides along the upper surface of the operating platform 21 and passes through the slit 23, and the peeled off polarizer 25 is spread downwards through the slit 23 and laid on a long strip. The translatable surface of the conveyor belt 26 translates on and with the translatable surface of the elongated conveyor belt 26 . As an option, the elo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com