Method of manufacturing field termination type insulated gate bipolar translator (IGBT) component with substrate provided with outward-extending layer

A technology of epitaxial layer and manufacturing field, which is applied in the field of IGBT device manufacturing, can solve the problems of broken, large silicon wafers, increased costs, etc., and achieve the effect of reducing the chance of fragmentation and saving huge costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

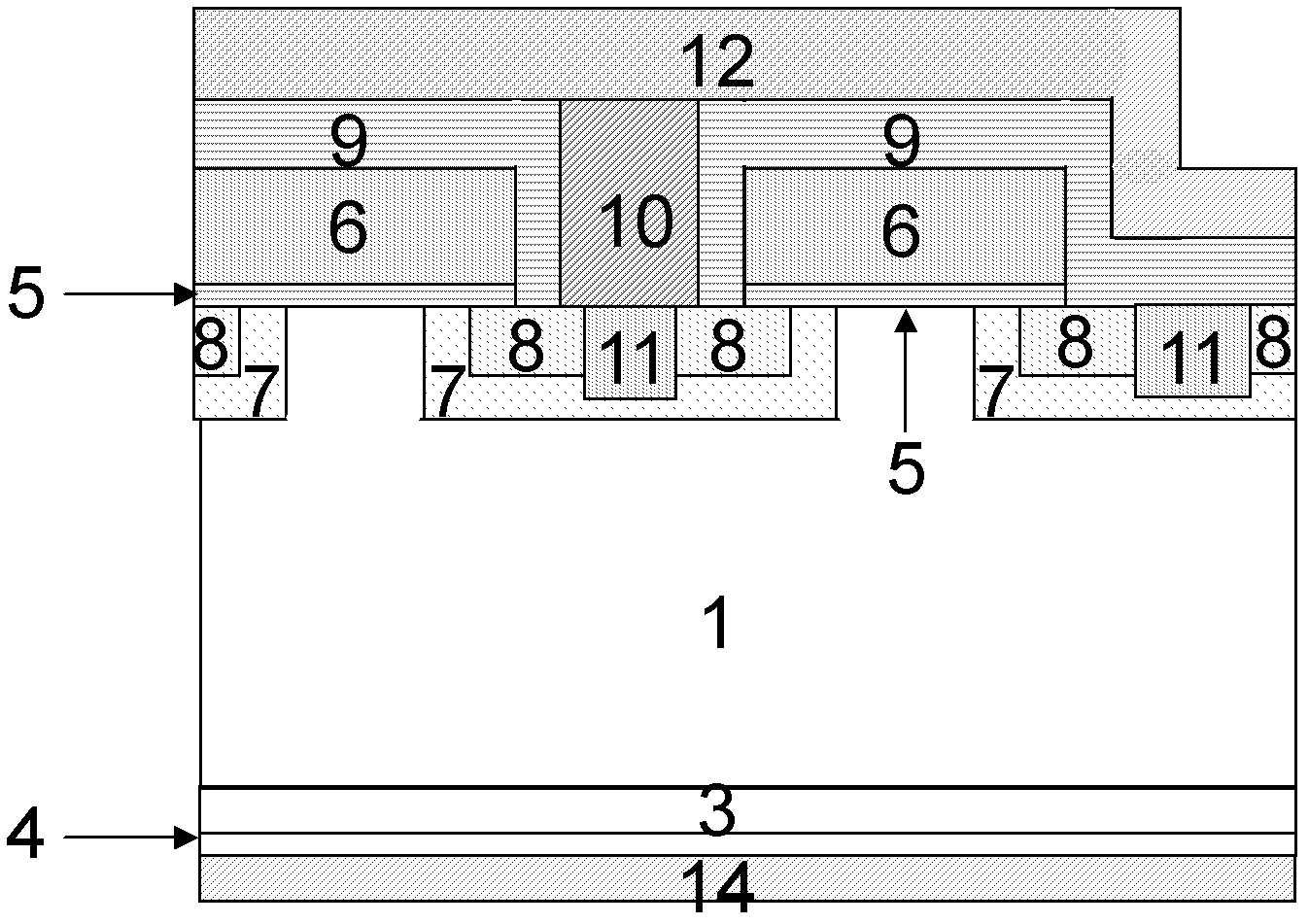

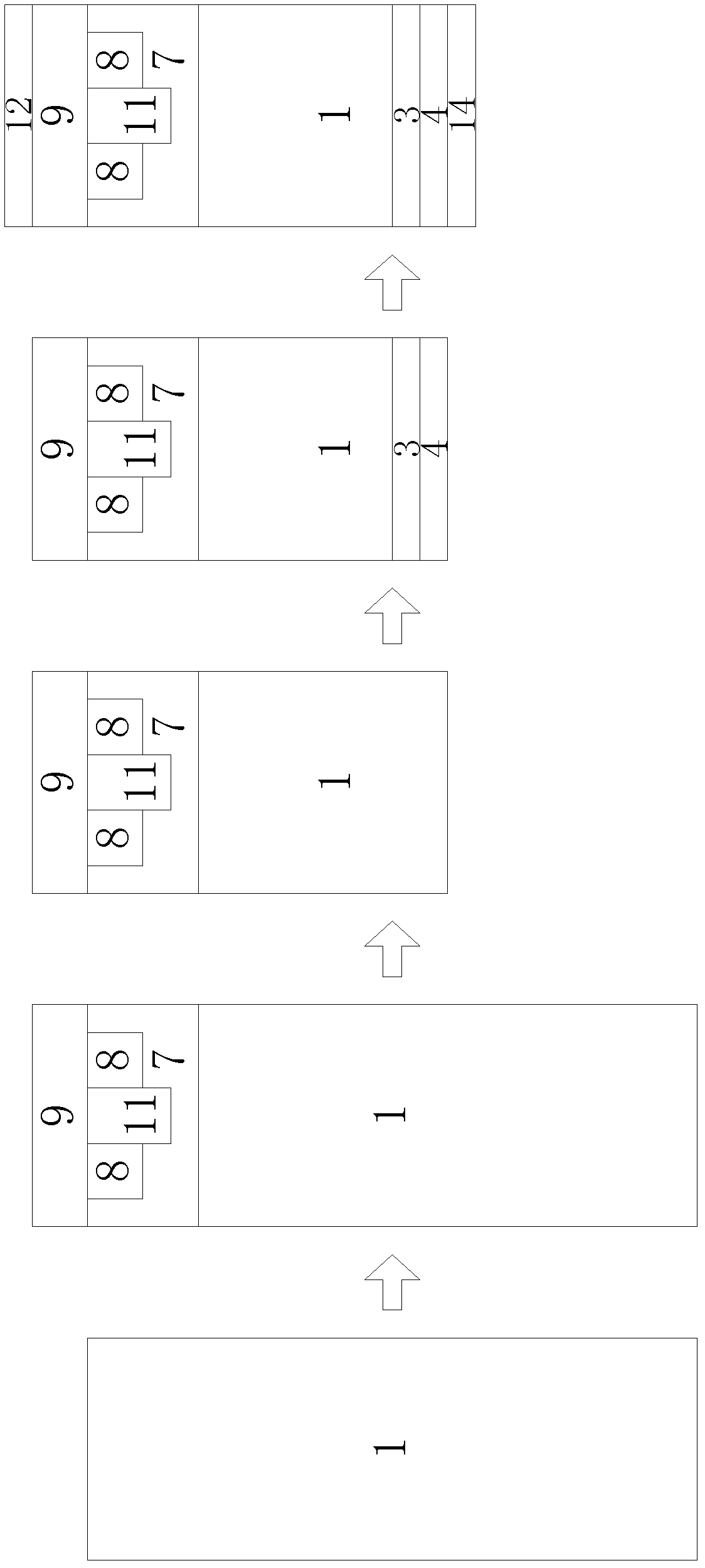

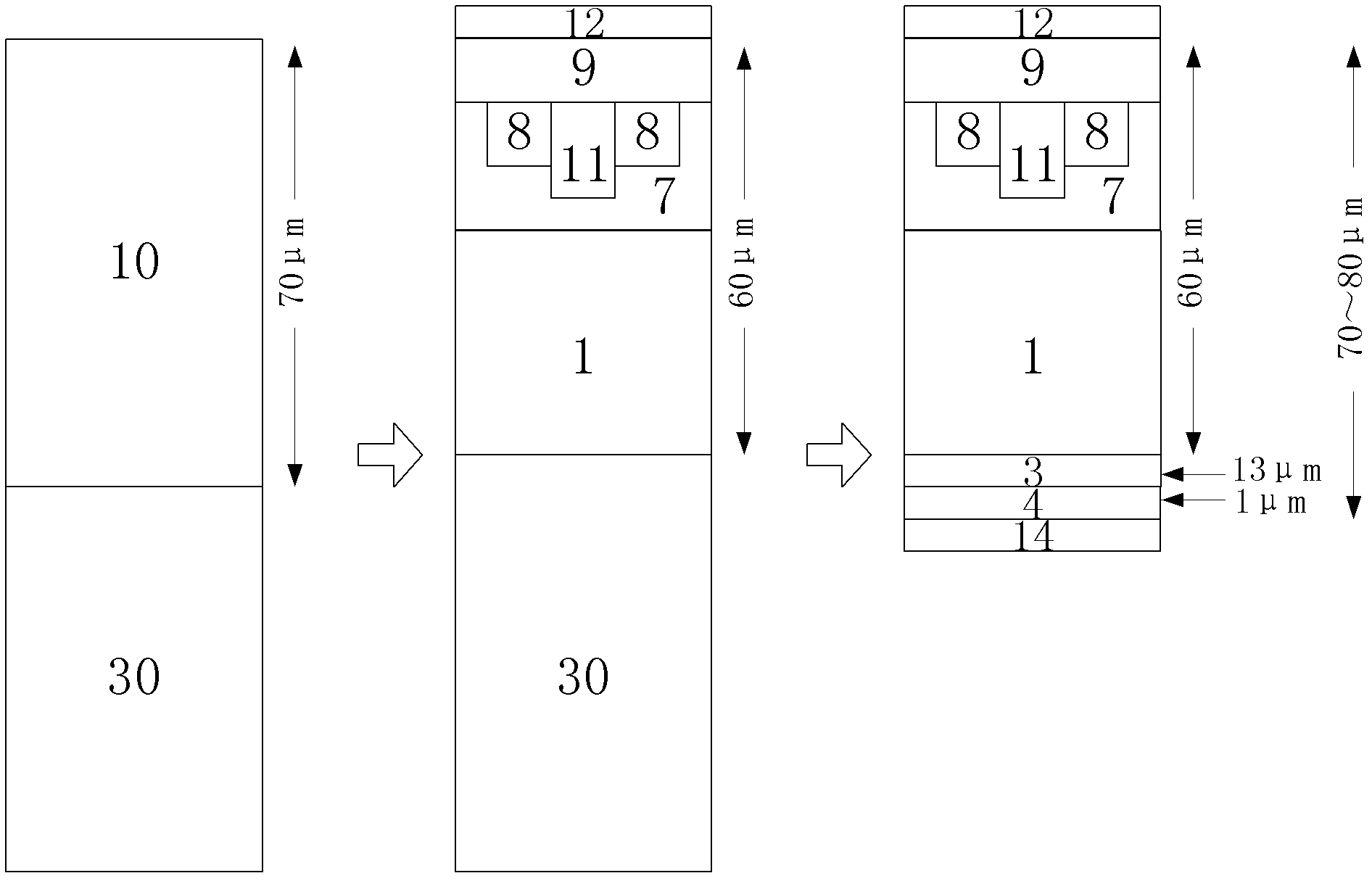

[0022] see image 3 , the method of the present invention to manufacture field-stop type IGBT device with the substrate that has epitaxial layer is:

[0023] In step 1, a silicon substrate 30 having an epitaxial layer 10 is selected.

[0024] The epitaxial layer 10 is preferably n-type medium and low doping, and the doped n-type impurity is phosphorus, for example, and the doping concentration is 1×10 11 ~1×10 14 atoms per cubic centimeter, preferably 6.5×10 13 Atoms per cubic centimeter, the epitaxial layer 10 has a thickness of 40-300 μm, preferably 70 μm. The epitaxial layer 10 can also be undoped or p-type doped.

[0025] The silicon substrate 30 is preferably n-type heavily doped silicon, and the doped n-type impurity is phosphorus, for example, with a doping concentration of 1×10 14 ~1×10 17 atoms per cubic centimeter, preferably 3×10 16 atoms per cubic centimeter. The silicon substrate 30 can also be undoped or p-type doped.

[0026] Fabricate the front structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com