Cup cover pressing device and full-automatic cup covering machine

A pressing device, fully automatic technology, applied in the direction of instruments, coin-operated equipment for distributing discrete items, coinless or similar appliances, etc., can solve the problems of damage, large space occupied by moving parts, and different heights, etc., to achieve The pressing process is smooth and stable, realizing intelligent control and taking up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: a cup lid pressing device.

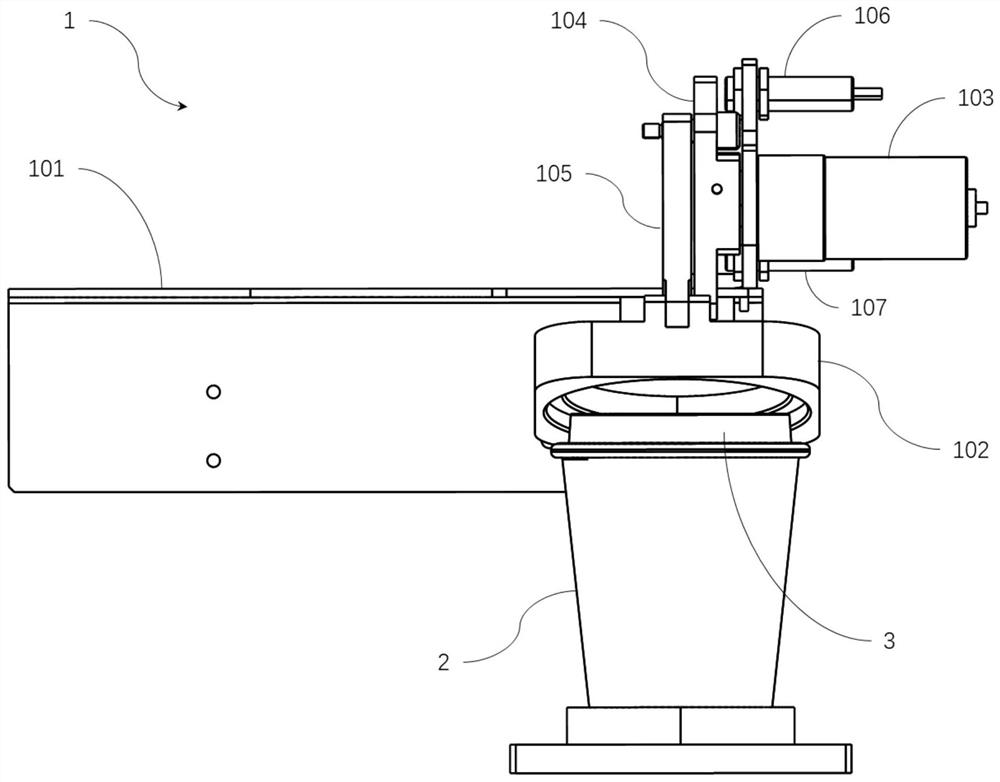

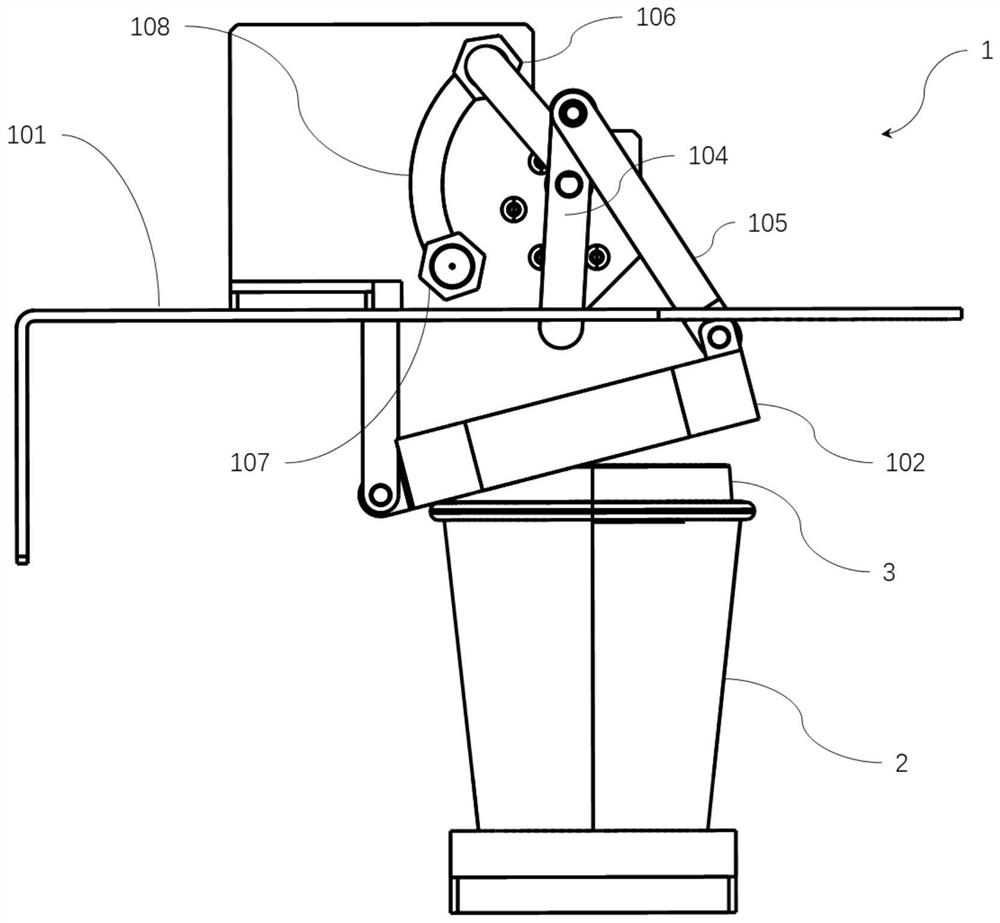

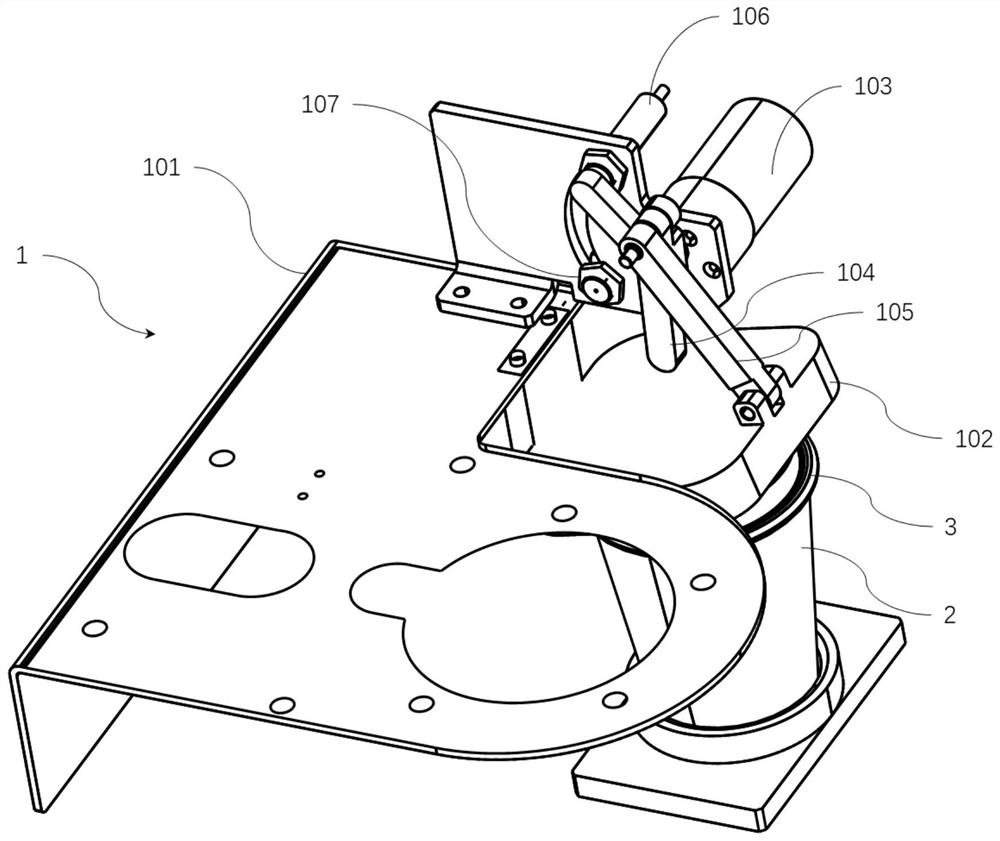

[0054] like Figure 1 to Figure 3 As shown, this embodiment is a cup lid pressing device, which includes a first bracket 101 , a lid pressing member 102 , a first motor 103 , a first driving arm 104 , and a second driving arm 105 . Wherein the first motor 103 , the first driving arm 104 , and the second driving arm 105 form a first driving mechanism for driving the lid pressing member 102 for pressing the cup 2 and the cup lid 3 located below. The first motor 103 in this embodiment is a servo motor with a reduction mechanism, which can drive the first driving arm 104 to rotate smoothly. Both the first driving mechanism and the gland member 102 are mounted on the first bracket 101 , wherein the first bracket 101 includes a plurality of auxiliary mounting brackets. The first bracket 101 , the capping member 102 , the first driving arm 104 , and the second driving arm 105 form a four-bar linkage mechanism, which converts the rot...

Embodiment 2

[0061] Embodiment two: a kind of fully automatic cup cover machine.

[0062] like Figure 9 and Figure 10 As shown, this embodiment is a fully automatic cup cover machine, which includes a housing 4 with an installation cavity 402 . This embodiment also includes a cup lid storage and separation device 5 , which is arranged on the upper part of the installation cavity 402 , and a lid dropping station 6 is formed from the lower end of the cup lid storage and separation device 5 to the bottom of the installation cavity 402 . The cup lid storage and separation device 5 is used to stack and store the cup lids 3 and separate and drop a single cup lid 3 to the cup 2 that is preset in the lid drop station 6 and is located on the drop path of the cup lid 3 . This embodiment also includes the cup lid pressing device 1 described in Embodiment 1, which is arranged on the upper part of the installation cavity 402 and is located on one side of the cup lid storage and separation device 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com