Fine double-sided planer

A double-sided planer and wood machine technology, which is applied in the direction of manufacturing flat surface processing machines, wood processing appliances, manufacturing tools, etc., can solve the problem of long production process flow, increased labor and human finished products, and lack of reliable compression constraints, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

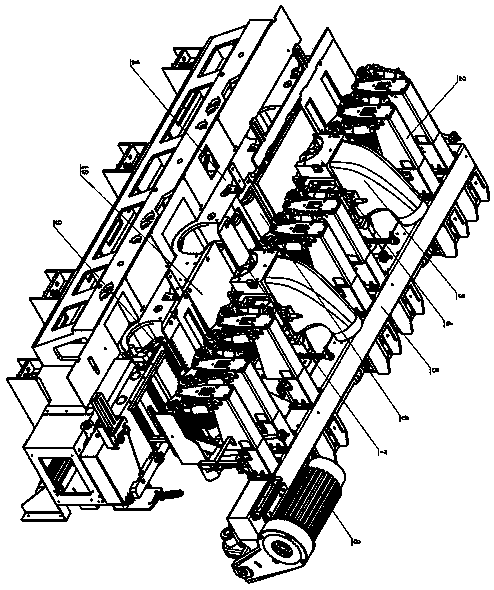

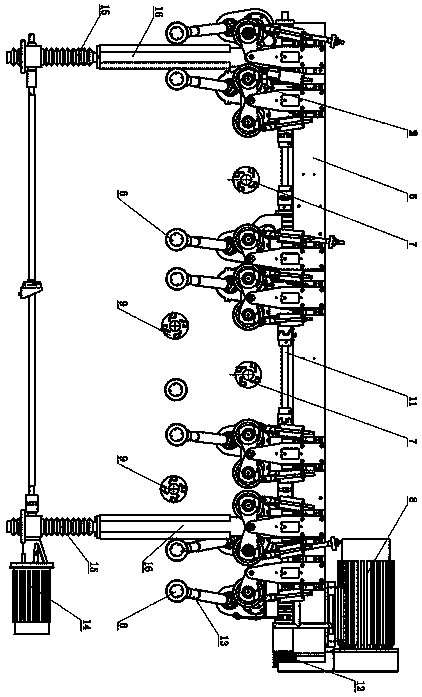

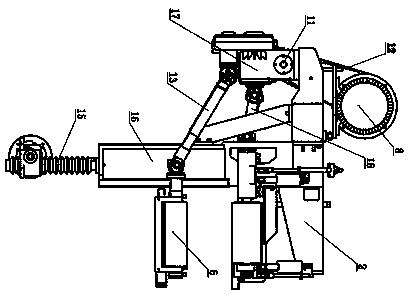

[0033] Such as figure 1 As shown in the fine double-sided planer, the double-sided planer includes a frame 1, and a workbench 10 is arranged on the frame 1, and the workbench 10 is used to support planed wood. Two lower planer knives 9 that can rotate at a high speed are supported on the frame 1 . Two upper planer knives 7 that can rotate at high speed are arranged above the table top of the work surface 10, and the cutter shafts of the two upper planer knives 7 are supported on the frame 1 through the upper planer shaft bearings, and the upper planer 7 and its cutter shafts are opposite to each other. The frame 1 can be adjusted by sliding up and down. The cutter shafts of the upper planer 7 and the lower planer 10 are connected to the planer motor through a belt transmission pair, and the axis lines of the upper planer 7 and the lower planer 10 are parallel to each other. There are also seven lower feeding rollers 6 that are rotatably supported on the frame 1, and the prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com