Hot sizing device and hot sizing method for thin-wall stamping part

A technology for stamping and thermal correction, which is applied in the field of thermal correction devices for thin-walled stampings, can solve problems such as warping and deformation of thin-walled stampings, and achieve the effects of avoiding warping, warping, and misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiment.

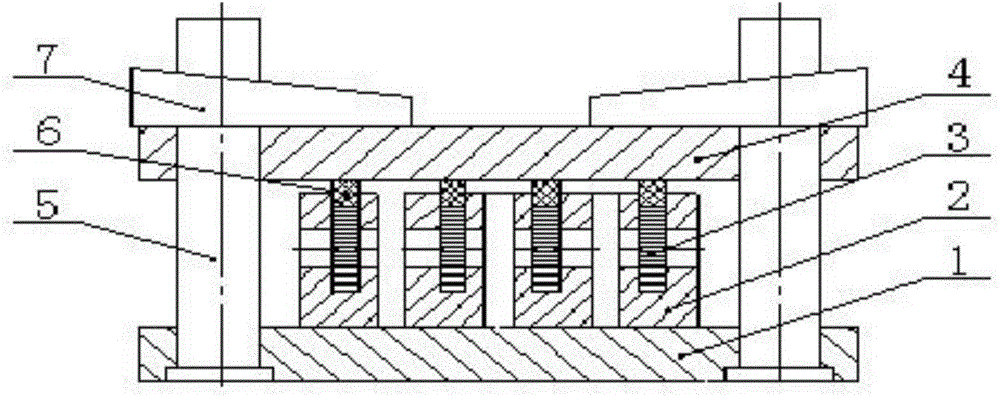

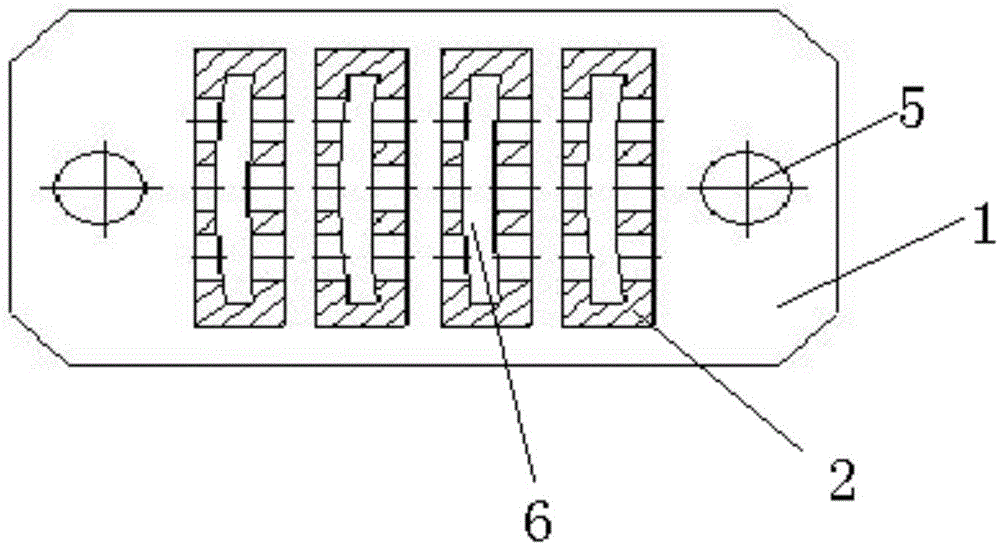

[0028] see figure 1 with figure 2 , the device of the present invention comprises a base plate 1, and positioning pins 5 fixedly arranged at both ends of the base plate 1, several loading boxes 2 are arranged on the base plate 1, and through holes for heat transfer are provided on the side walls of the loading boxes 2, and the loading boxes 2 Several thin-wall stamping parts 3 can be stacked inside, the cavity in the loading box 2 matches the size and structure of the thin-wall stamping parts 3, and the stacking height of several thin-wall stamping parts 3 is flush with the upper plane of the loading box. The upper end of the loading box 2 is provided with a pressing plate 4, the pressing plate 4 is set on the positioning pin 5, the lower end of the pressing plate 4 is provided with a pressing block 6, and the pressing block 6 is pressed on the thin-walled stamping part 3, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com