Rope releasing device for unmanned aerial vehicle

A machine rope releaser and UAV technology, which is applied in the field of fire rescue equipment, can solve the problem that the UAV rope releaser is difficult to arrange the traction rope in high buildings smoothly, and achieve the effect of convenient layout, high efficiency and easy control of the traction rope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

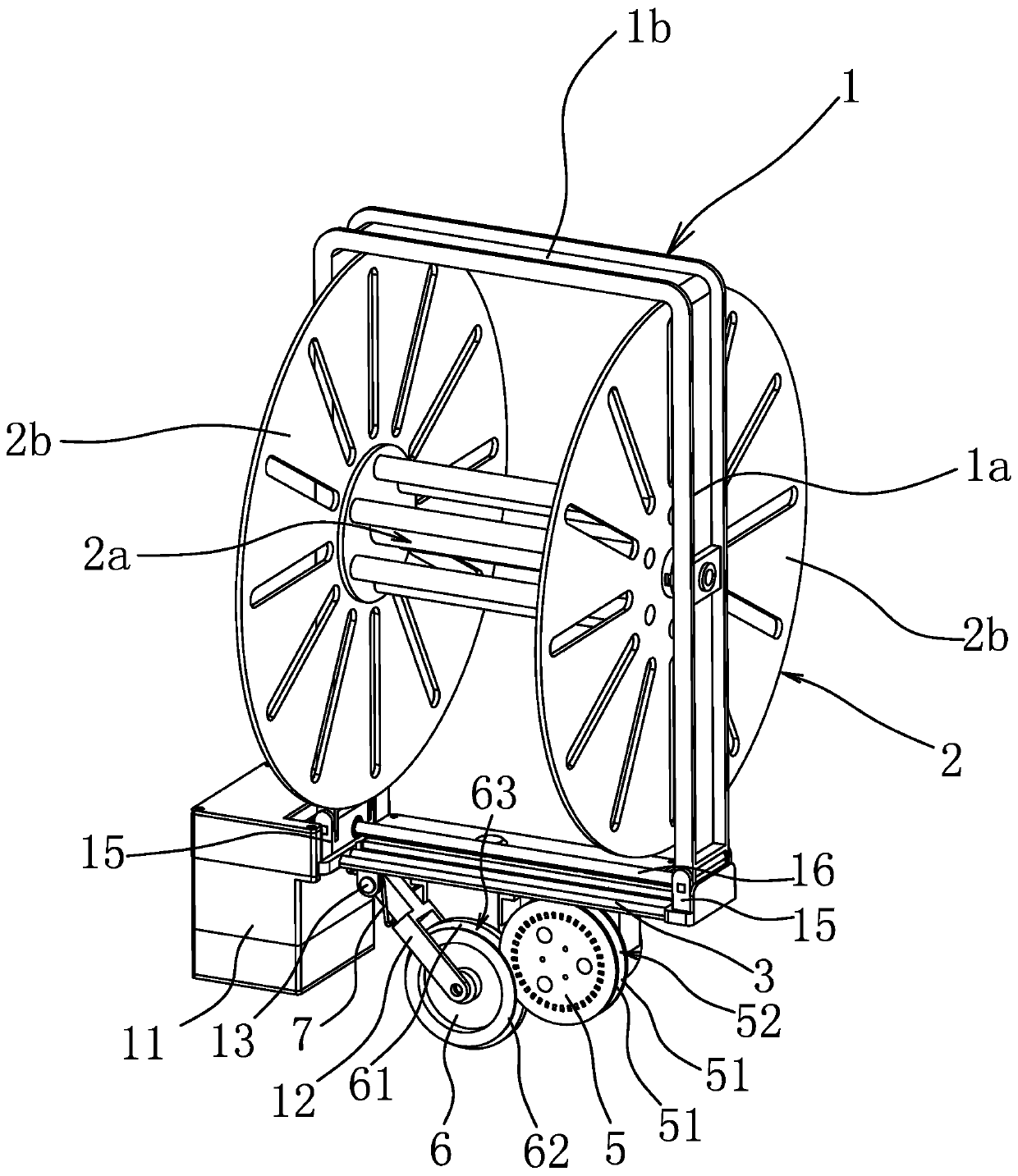

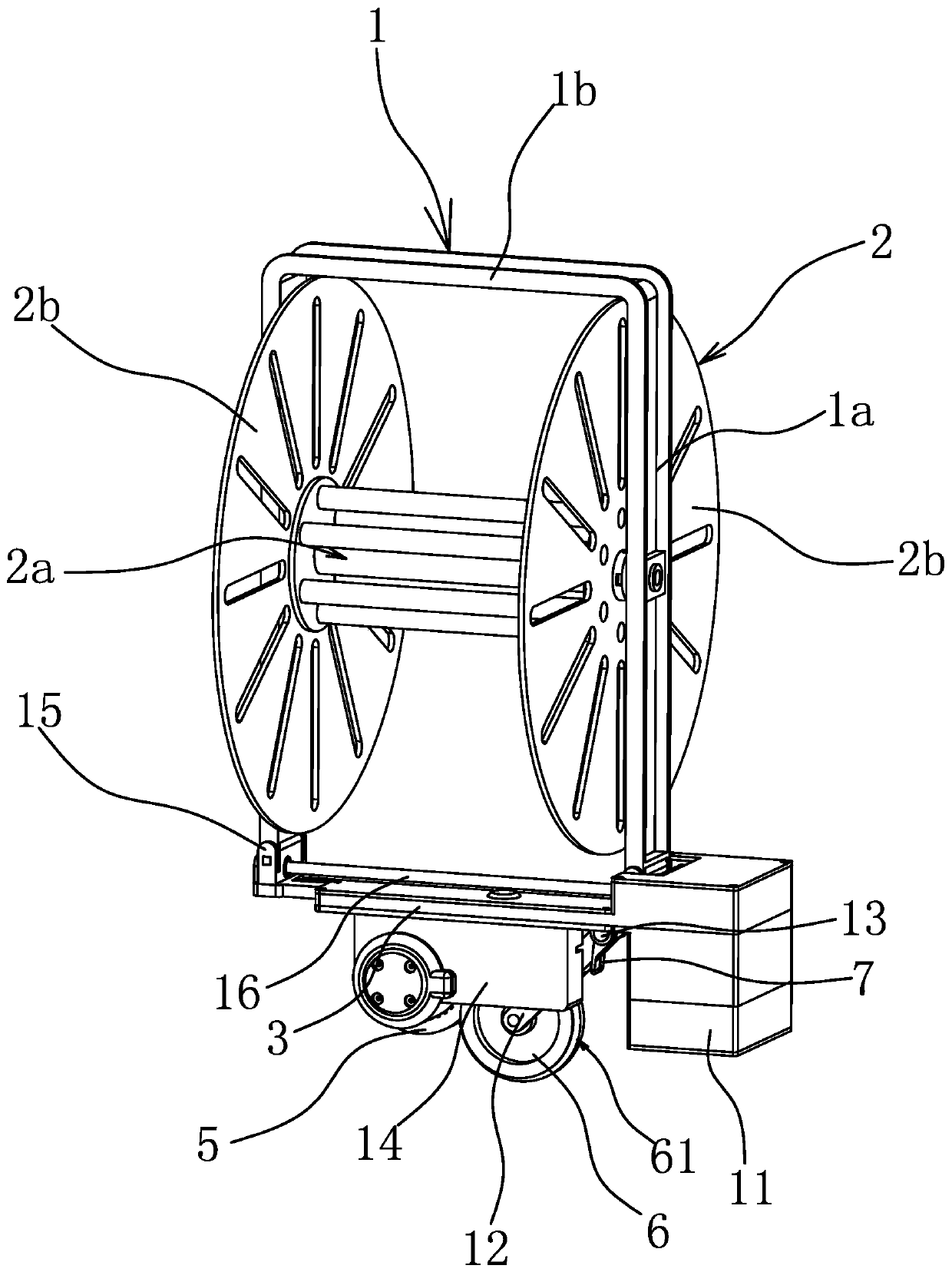

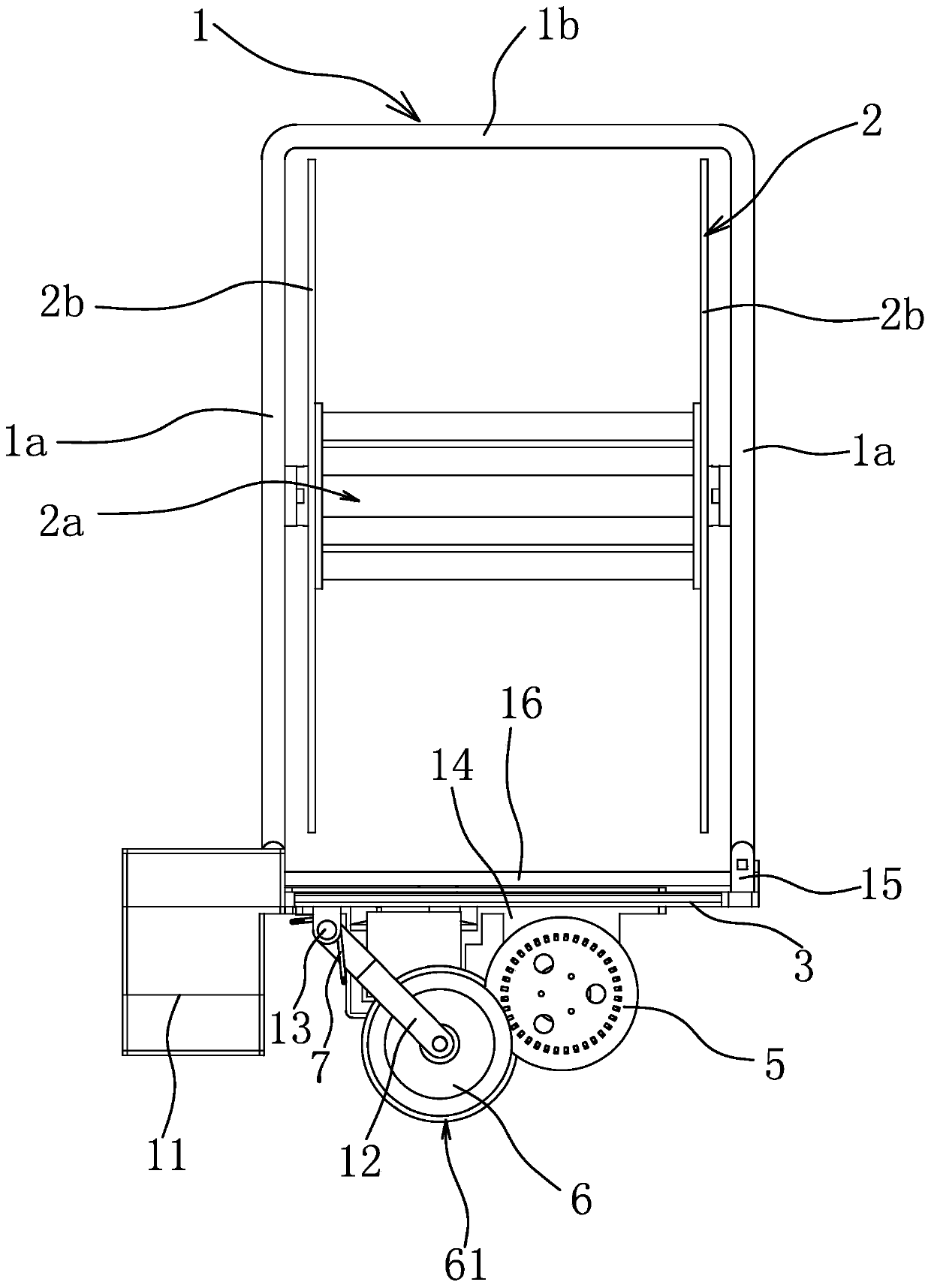

[0047] Such as figure 1 , figure 2 with image 3 As shown, the UAV rope release device includes a rope reel support 1, a throwing frame 3, and a rope reel 2 for winding the traction rope. The rope reel support 1 and the throwing frame 3 are made of aluminum alloy and engineering materials. Composite formation. The throwing frame 3 is strip-shaped, the rope reel support 1 is U-shaped and includes a top beam 1b and two oppositely arranged side support beams 1a, and the rope reel 2 includes a reel 2a, and the two ends of the reel 2a are respectively connected with a 2a is perpendicular to the rope retaining plate 2b, and the two ends of the reel 2a are rotatably connected to two side support beams 1a. The top beam 1b is used to connect with the unmanned aerial vehicle 22, and the throwing frame 3 is connected between the lower ends of the two side support beams 1a. The throwing frame 3 can be separated from the rope reel support 1 by remote control. 3 is provided with a main...

Embodiment 2

[0058] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 16 As shown, the main rotating part is the driving roller 8, the driven part is the driven roller 9, the rope reel 2 has a reel 2a, and the throwing frame 3 is also provided with an installation port 31, and the driving roller 8 and the driven roller 9 are all arranged on The installation openings 31 are all arranged parallel to the reel 2a, and there is a gap between the driving roller 8 and the driven roller 9 for the traction rope to pass through and to clamp the traction rope. When in use, the traction rope passes between the driving roller 8 and the driven roller 9 after being drawn from the rope reel 2 and is clamped by the driving roller 8 and the driven roller 9, so that when the throwing frame 3 falls, the throwing rope Throwing frame 3 just can fall together with traction rope. Moreover, during the take-off process of the UAV, the rot...

Embodiment 3

[0060] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that the elastic part 7 of Embodiment 1 can use a tension spring, one end of the tension spring is connected to the throwing frame 3, and the other end of the tension spring The end of the connecting wheel frame 12 close to the driven wheel 6 relies on the tension of the extension spring so that the driven wheel 6 has a tendency to always lean against the driving wheel 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com