Filter stick cutting and section detecting device

A detection device and filter rod technology, which is applied in the fields of application, tobacco, and paper cigarette manufacturing, can solve problems such as inaccurate and reliable detection results, broken cutting sections, and long transmission distances, and achieve compact structure, smooth cross-section, and improved filter rod quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

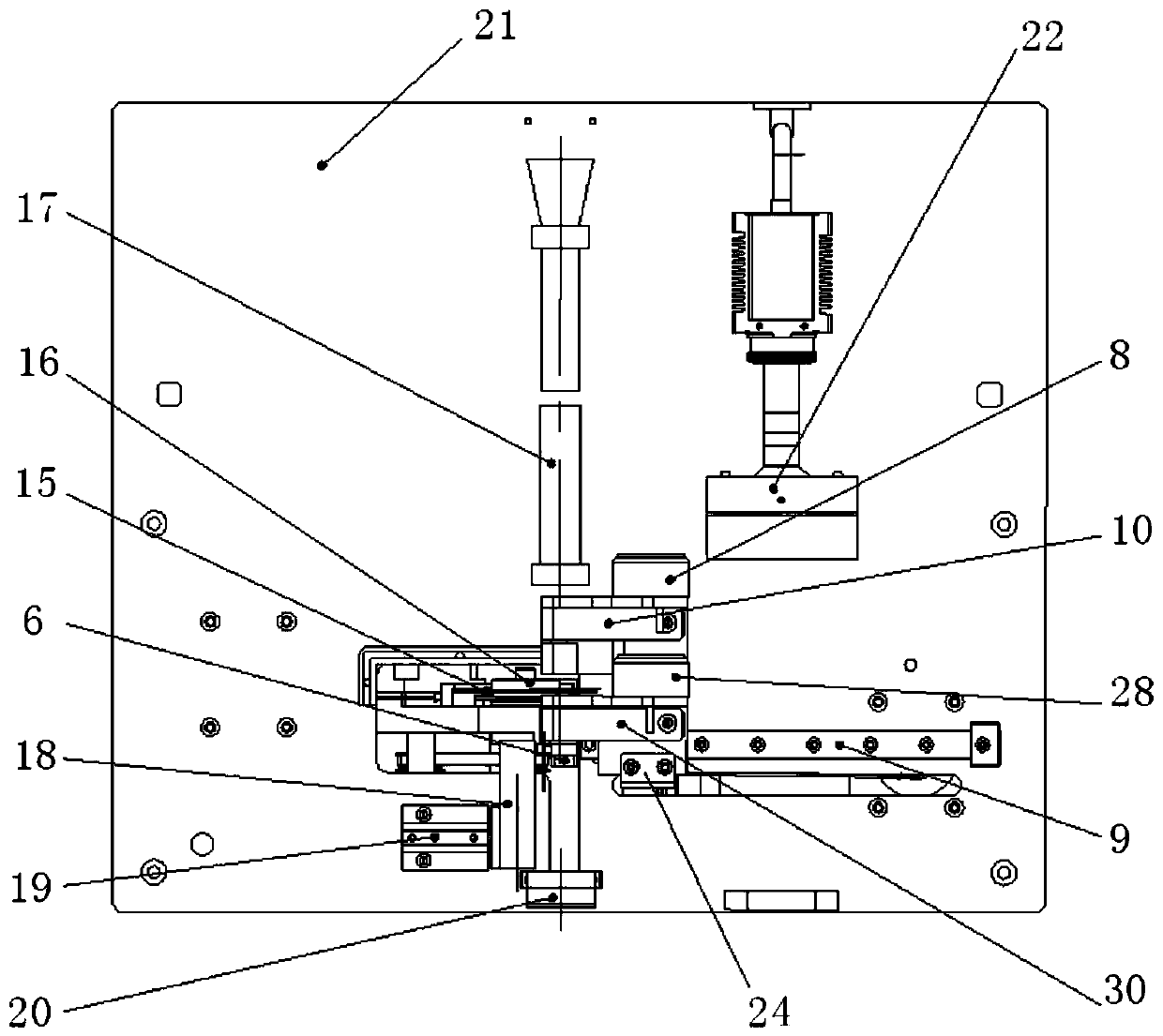

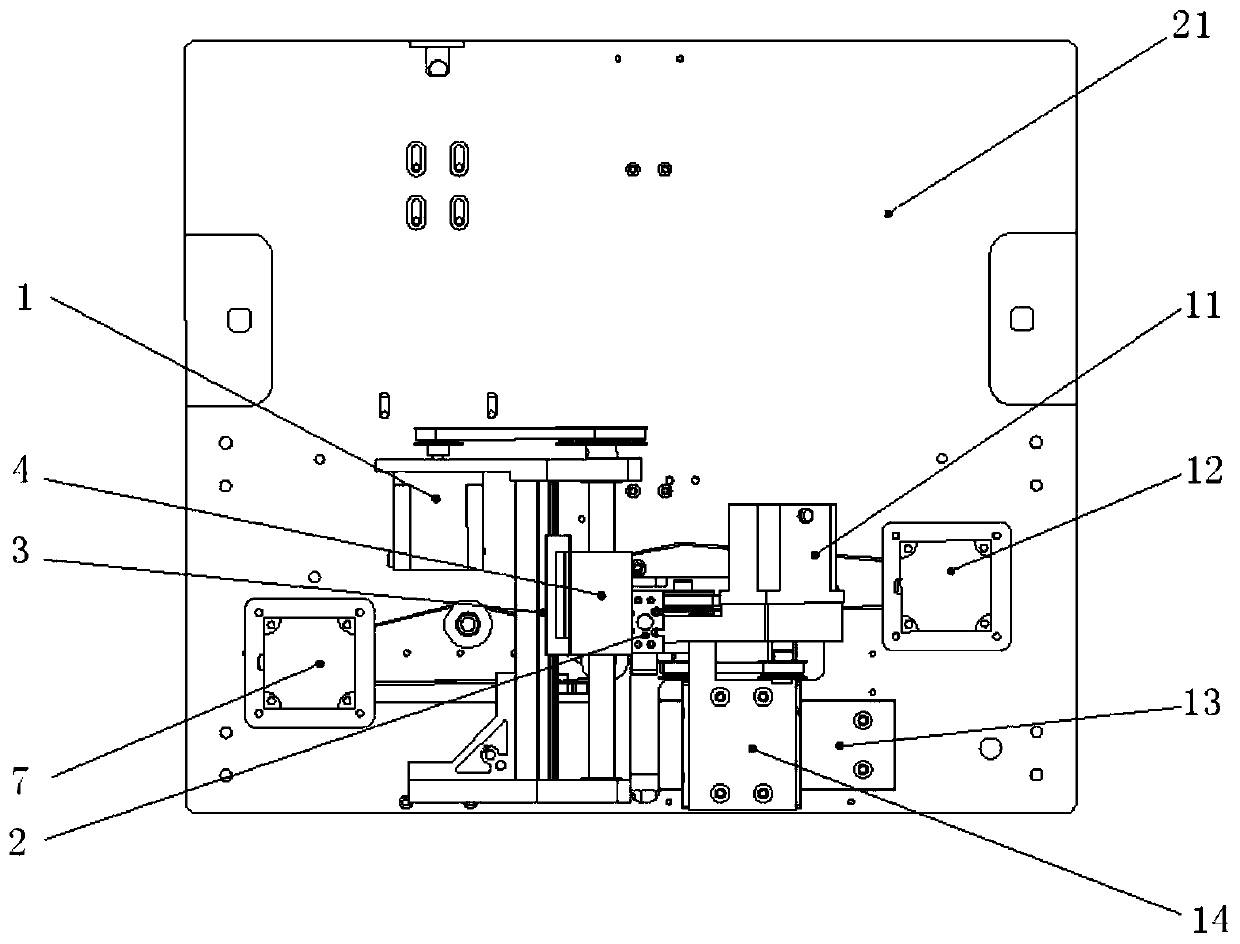

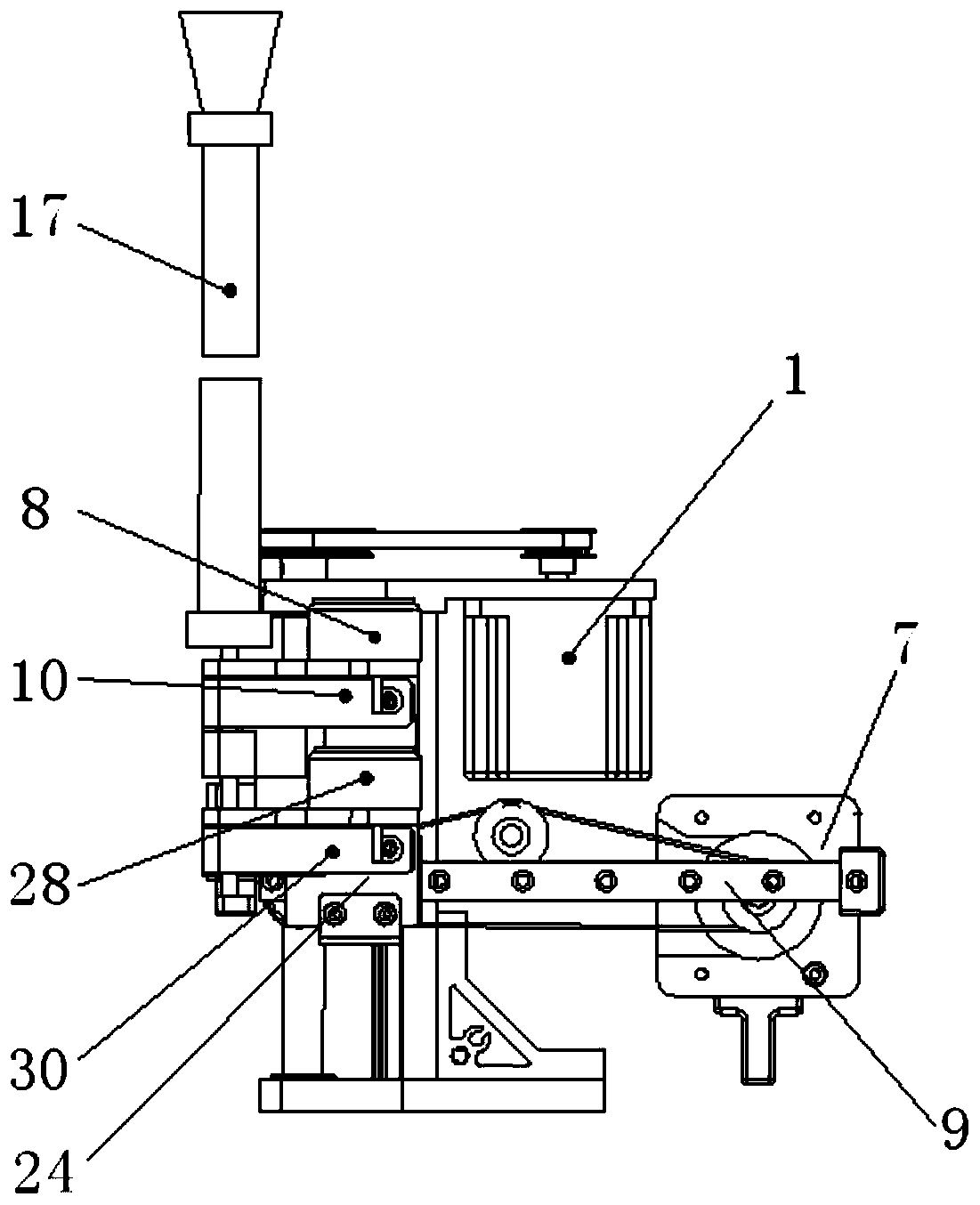

[0032] Refer to attached figure 1 and 2 As shown, the filter rod cutting and cross-section detection device of this embodiment includes a fixed base plate 21 vertically arranged on the ground and a filter rod guide mechanism, a positioning mechanism, a clamping mechanism, a cutting mechanism and a cross-section detection mechanism arranged on the front and rear sides of the base plate 21. mechanism.

[0033] The filter rod guide mechanism includes an upper guide tube 17 and a lower guide tube 18, the upper guide tube 17 is vertically fixed on the upper part of the front side of the base plate 21, and the lower guide tube 18 is vertically and movable left and right arranged on the base plate 21 lower front side. Driven by the first power mechanism, the lower guide pipe 18 can move to a position communicating with the upper guide pipe 17, providing a guide passage for the upper filter rod 23 to fall after cutting. Wherein, the first power mechanism adopts a telescopic air cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com