Inclined cross type grabbing device for steeping mud packaging production

A grabbing device and cross-type technology, which are applied in the field of inclined cross grabbing devices for foamed mud packaging production, can solve the problems of easy falling off of foamed mud blocks, inaccurate positioning of cartons, inconvenient transportation of foamed mud blocks, etc. , to achieve the effect of simple structure, convenient insertion, convenient packing and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

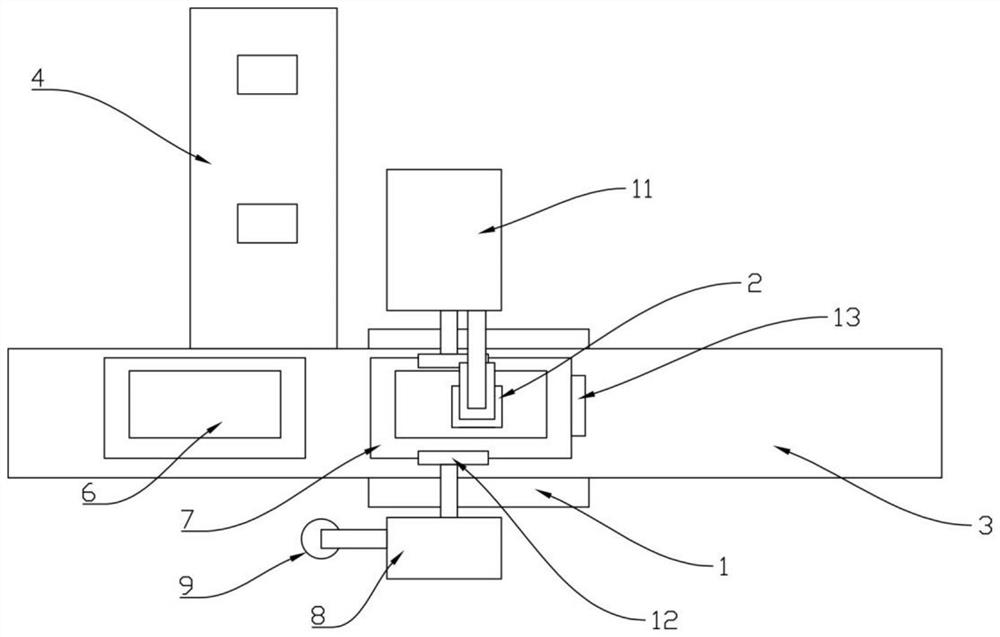

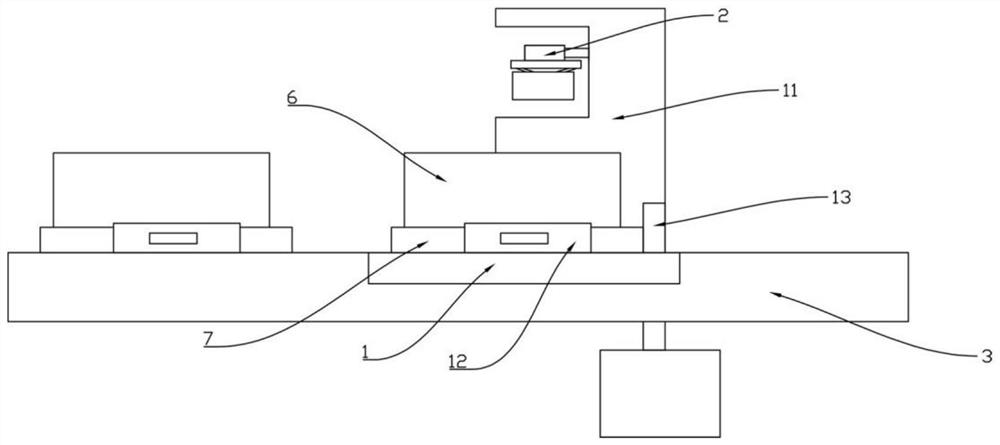

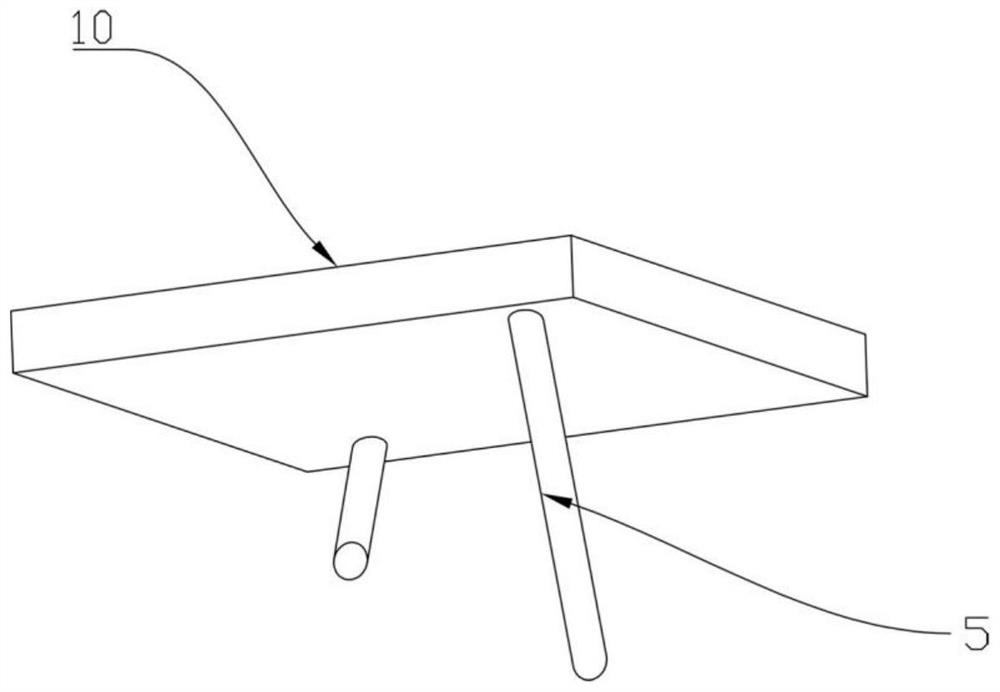

[0025] refer to Figure 1-5 , an inclined cross-type grabbing device for foaming mud packaging production, including a packing platform 1, a mechanical gripper 2, a transfer conveyor belt 3 and a foaming mud conveyor belt 4, and the mechanical gripper 2 is arranged above the packing platform 1, and the foaming The mud conveyor belt 4 and the transfer conveyor belt 3 are crossed, and the mechanical gripper 2 moves the foamed mud blocks of the foamed mud conveyor belt 4 to the top of the packing platform 1, so that the foamed mud blocks can be transported from the transfer conveyor belt 3 after being packed on the packing platform 1. When conveyed away, the mechanical gripper 2 includes two obliquely arranged and intersecting plunger rods 5, and the two intersecting plunger rods 5 do not contact each other. The packing platform 1 is provided with a packaging carton 6 for receiving the foamed mud block and a carrying package. The carton 6 moves on the conveying tray 7 on the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com