Poking and separating type automatic cup falling device

An automatic and cup-dropping technology, which is applied in the directions of packaging, transportation and packaging, and unstacking of objects, etc., can solve the problems of poor accuracy, narrow application range, and poor separation effect, so as to achieve reasonable structure and accurate action Reliable, drop-accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described below in conjunction with embodiment and accompanying drawing.

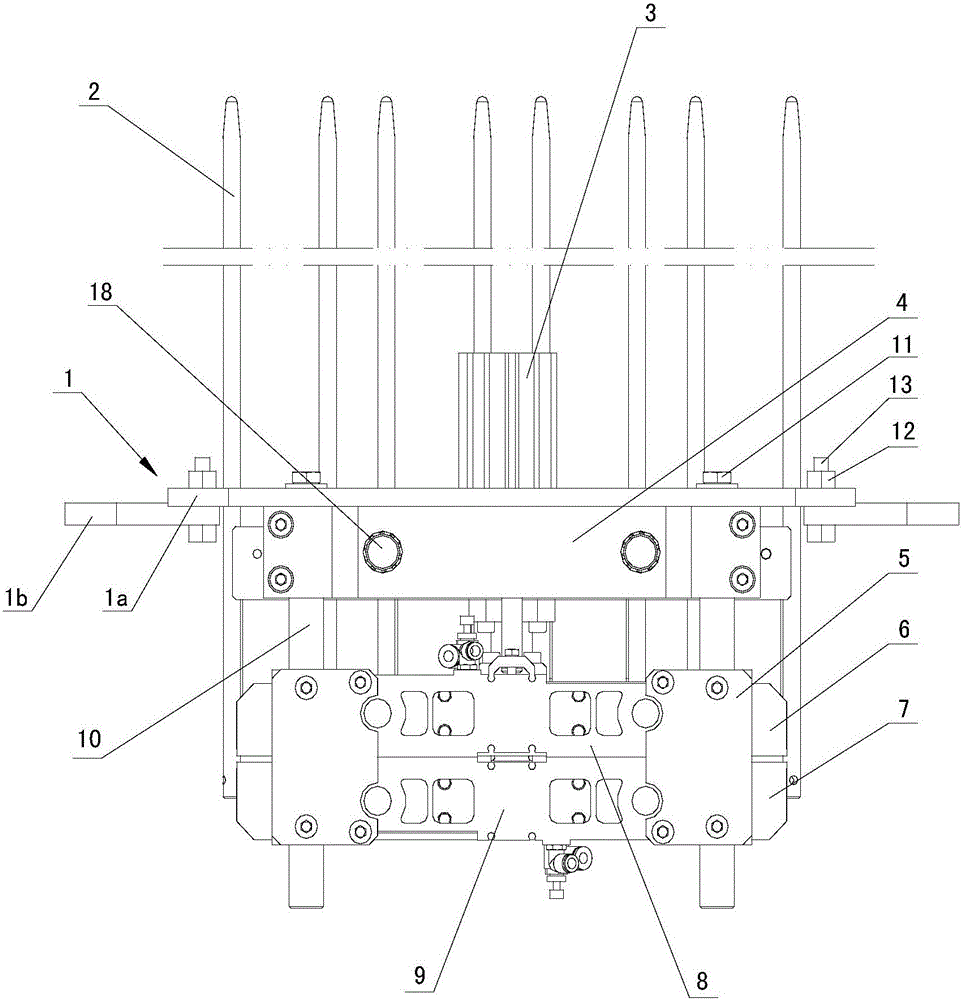

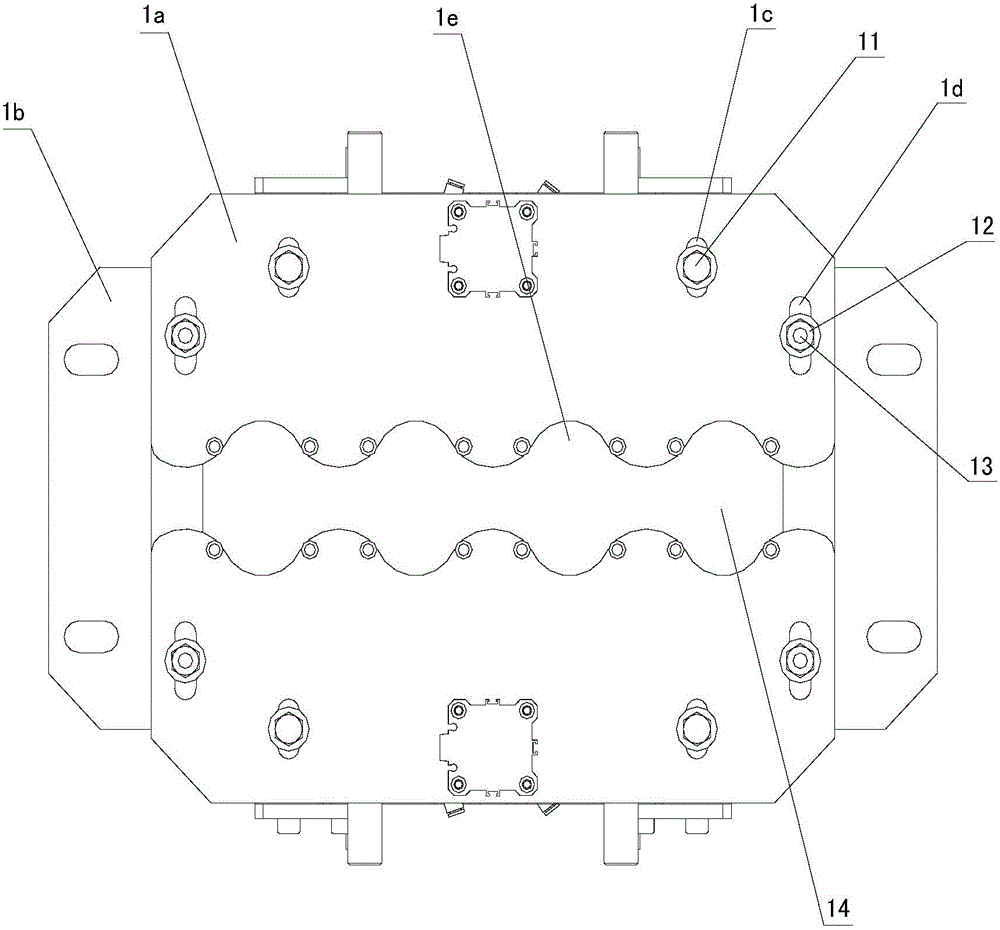

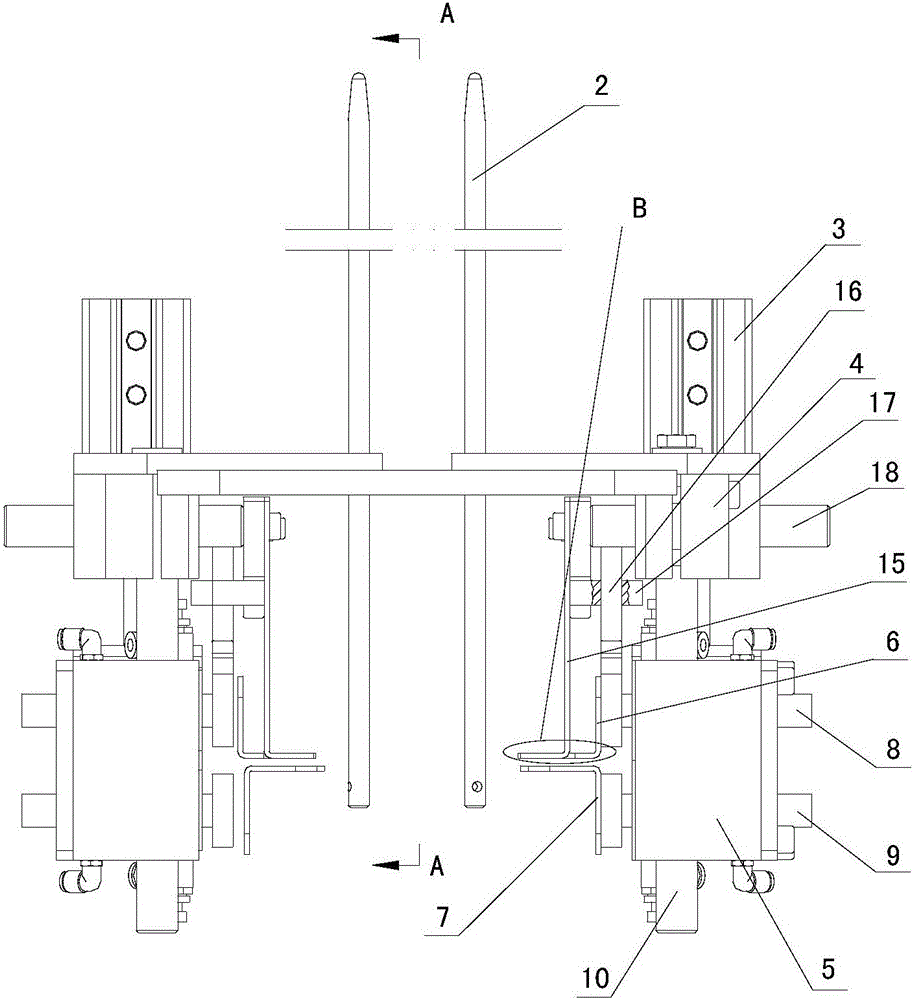

[0014] see figure 1 , figure 2 , image 3 , Figure 4

[0015] The pull-off type automatic cup drop device provided by the present invention has a platen 1, and a row of through holes 14 for passing through the packaging cups are arranged on the platen. A set of railings 2 are fixed on the edge of each through hole 14 to pass through the center of each through hole. The vertical plane of the line is the center plane, and two sets of pull-off mechanisms are arranged symmetrically along the center plane below the platen 1 . Each set of pull-off mechanism has three cylinders, wherein the first cylinder 3 is fixed on the upper side of the platen 1, the second cylinder 8 and the third cylinder 9 are located below the platen 1 and are jointly fixed with a cylinder frame 5, the second The piston rod of a cylinder 3 is vertical, and the piston rods of the second cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com