Reinforcement Welded Mesh Weft Line Positioning Device

A technology of steel welded mesh and positioning device, which is applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., and can solve problems such as limited position, waste products, and uneven weft outcropping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

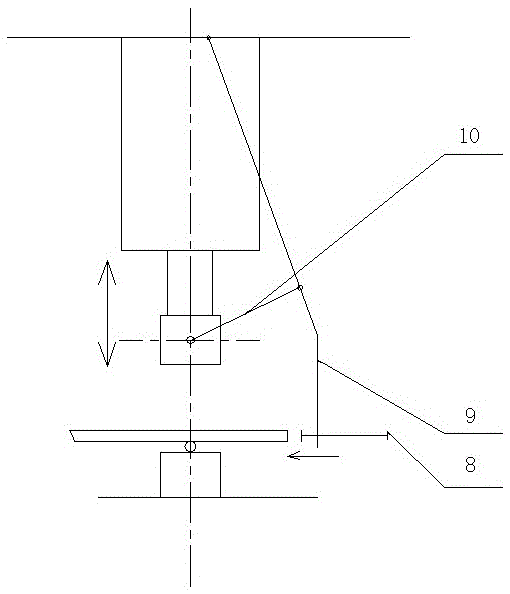

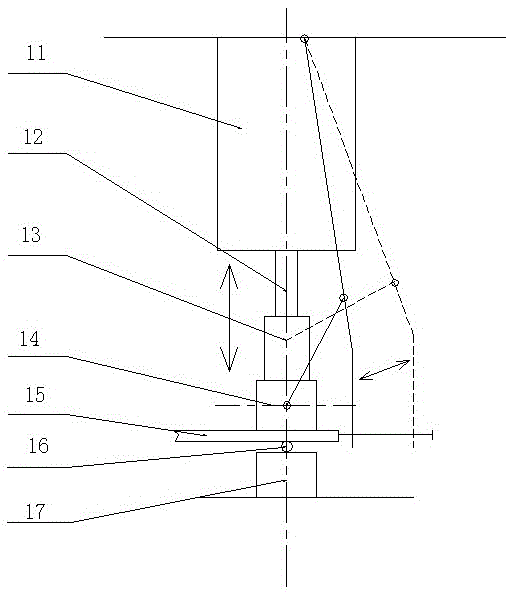

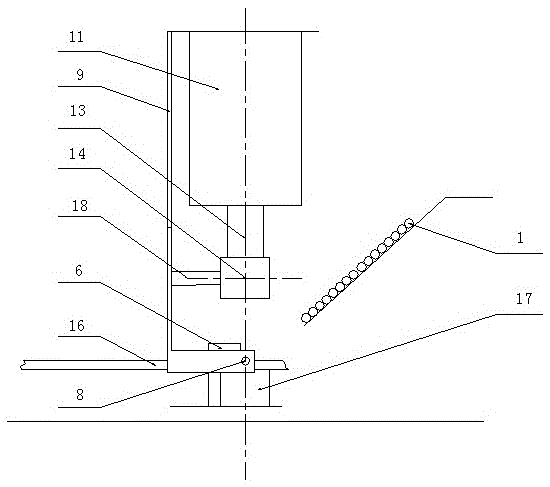

[0012] from figure 1 , figure 2 , image 3 It can be seen that the weft line positioning device for welded steel mesh of the present invention includes a fixed column 18, a connecting plate 10, a swing bar 9, and a push plate 8; , the other end of connecting plate 10 is hinged with fork 9, and the upper end of fork 9 is connected on the welded mesh main frame, and its lower end is connected with push plate 8. Wherein, the connecting plate 10, the swing rod 9, and the fixed column 18 form a link mechanism, and the adjustable push plate 8 is used to adjust the position of the weft thread 15 to be positioned. The position of the push plate 8 is adjustable, that is, the position of the push plate 8 can be adjusted horizontally relative to the fork 9.

[0013] Wherein, the front end of the fixed column 18 is fixedly connected behind the electrode block 14 at the rightmost end of the welding net host; the upper end of the swing rod 9 is hinged on the working cylinder 11 at the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com