Drying frame of non-metallic mine molding filter cakes

A non-metallic ore forming and drying frame technology, which is applied in the direction of drying solid materials, drying chamber/container, drying, etc., can solve the problems that cannot meet the needs of the production and development of the non-metallic ore industry, the filter cake is easily broken, and the work efficiency is low and other problems, to achieve the effect of good ventilation and drying, reduce the probability of fragmentation, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

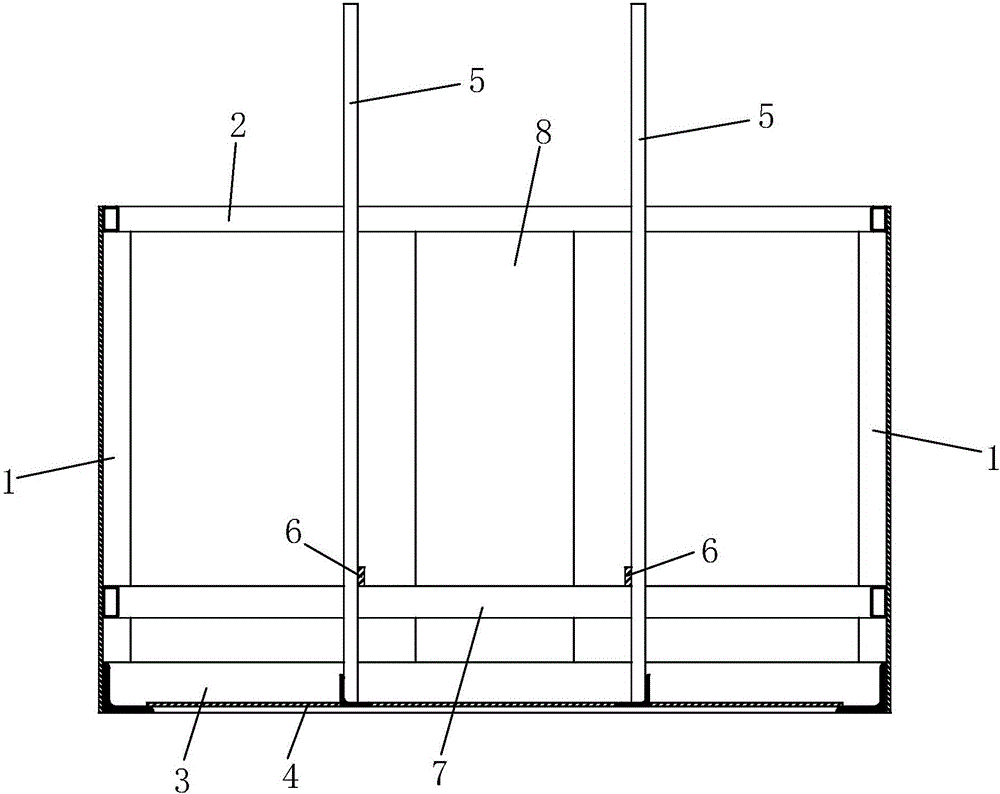

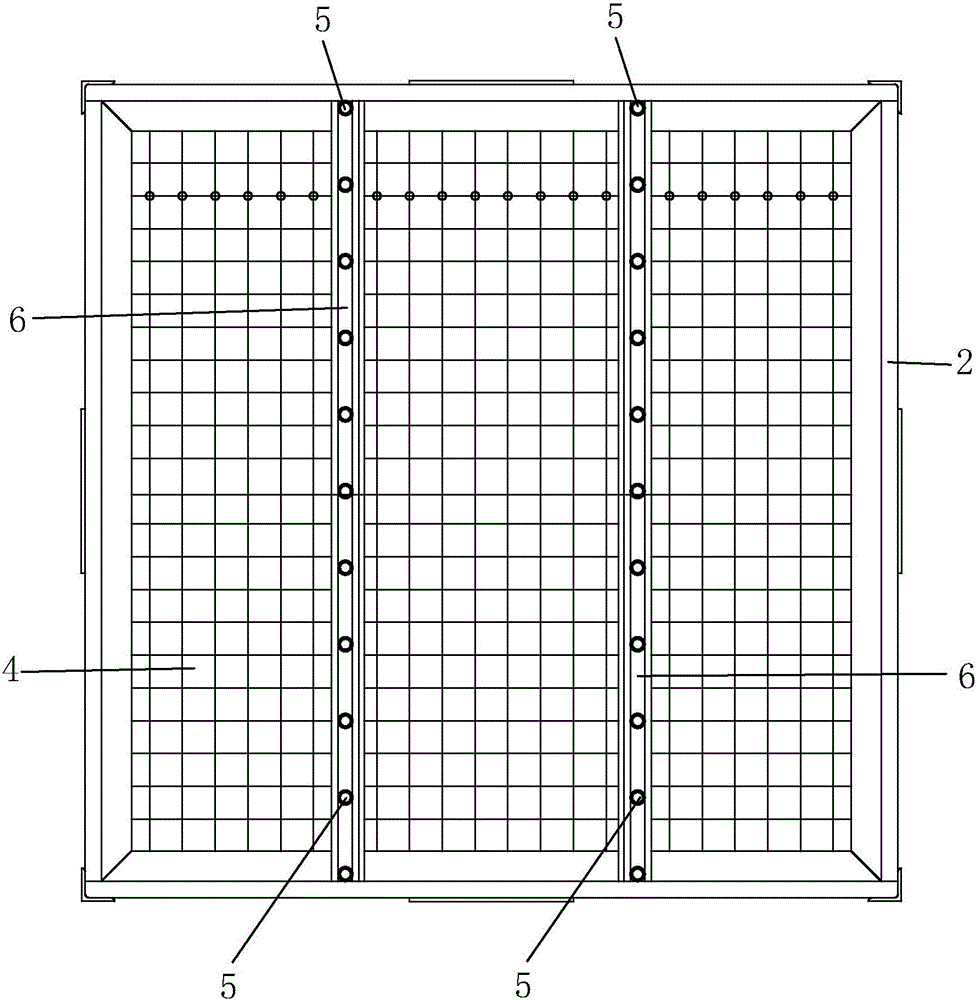

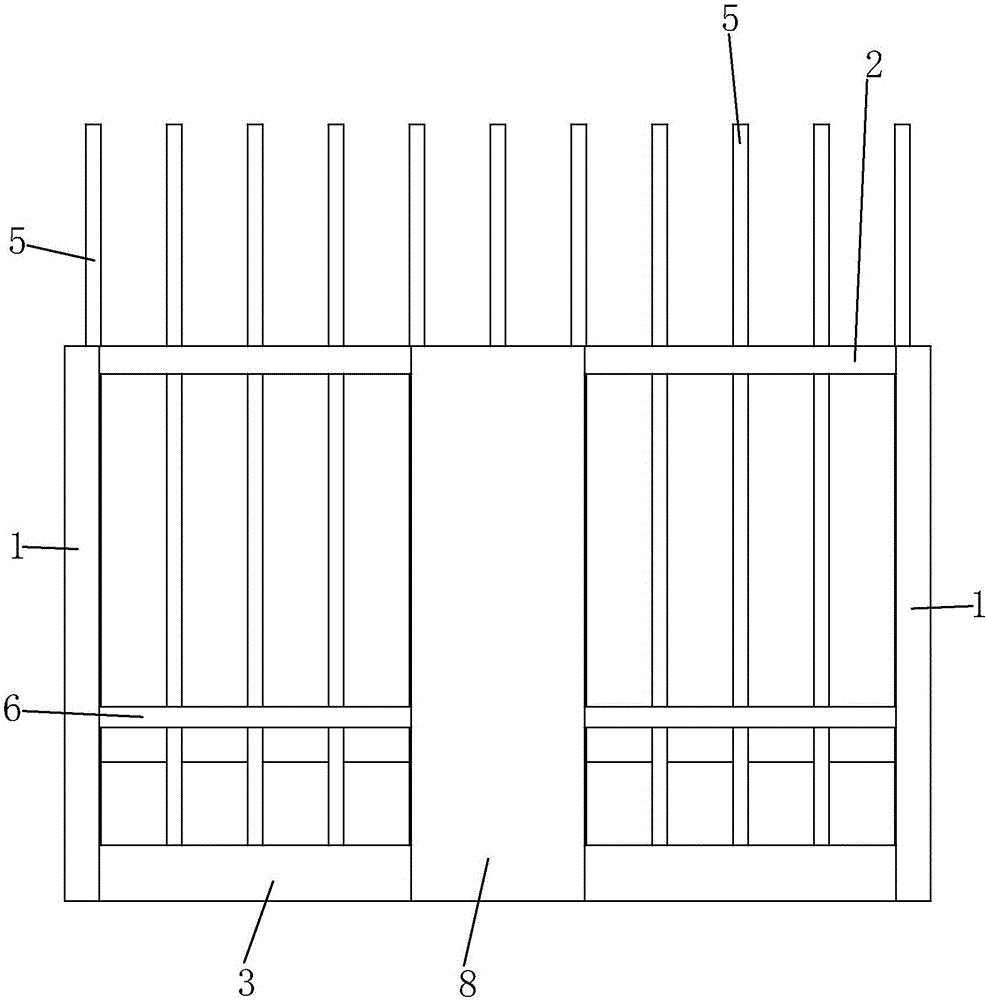

[0017] Embodiment: A kind of drying frame of non-metallic mineral shaped filter cake

[0018] The main body of the drying frame is a frame, which is mainly composed of four columns 1, four upper frames 2, four lower frames 3 and a base plate 4. The columns 1 are vertically set up on the four corners of the frame, and each upper frame 2. It is horizontally and fixedly connected between the tops of two upright columns 1. The four upper frames 2 form a rectangle or a square. Each lower frame 3 is horizontally and fixedly connected between the bottom ends of two upright columns 1. The four lower frames 3 to form a rectangle or a square, the bottom plate 4 is fixedly connected to the four lower frames 3 and serves as the bottom supporting surface of the frame, the top of the frame is an open structure; the inside of the frame is vertical Be provided with at least two rows of guide rods 5, each row of guide rods 5 is made up of a plurality of guide rods 5, the number of guide rods 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com