Ore extraction and transfer device

A transfer device and ore mining technology, applied in the direction of grain processing, etc., can solve the problems of car damage, box impact, high maintenance costs, etc., and achieve the effects of improving work efficiency, saving crushing time, and simple and reliable adjustment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

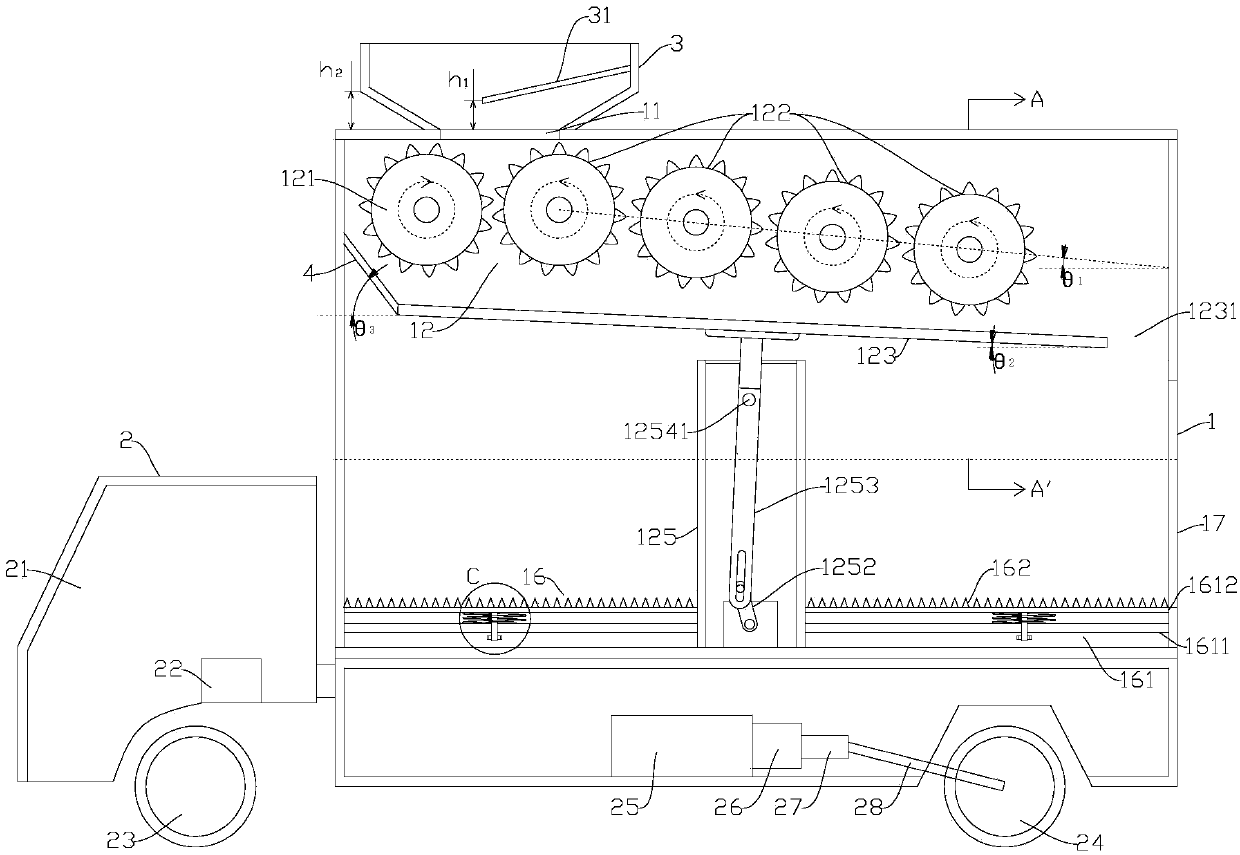

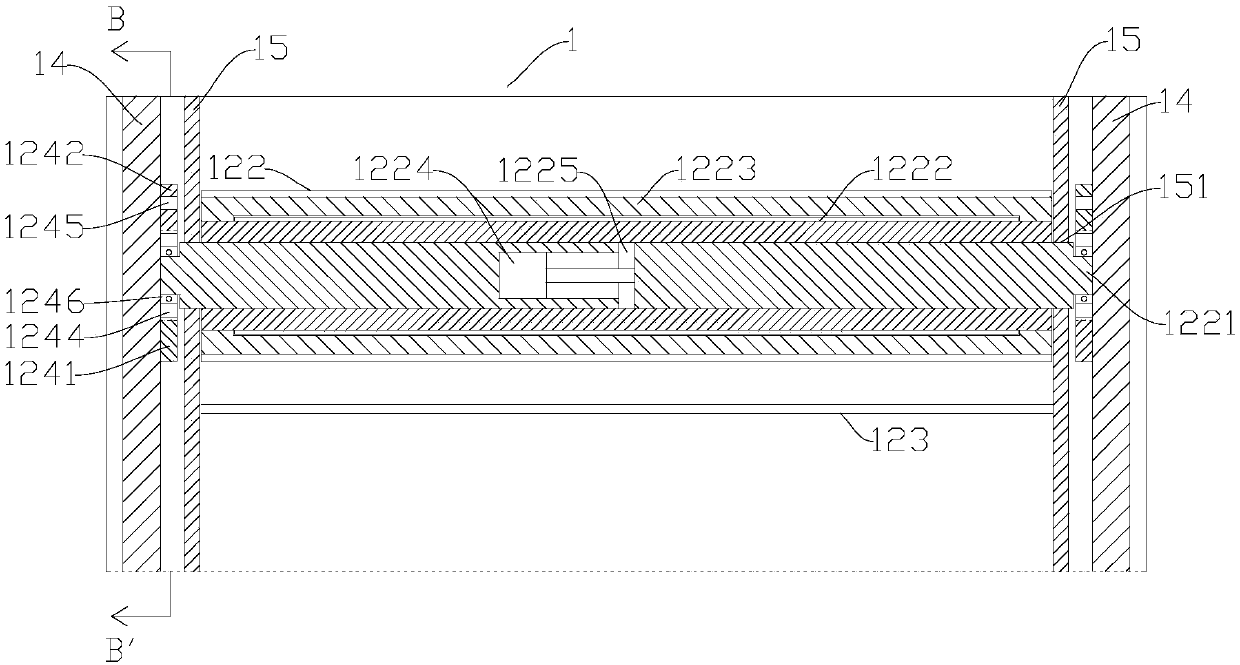

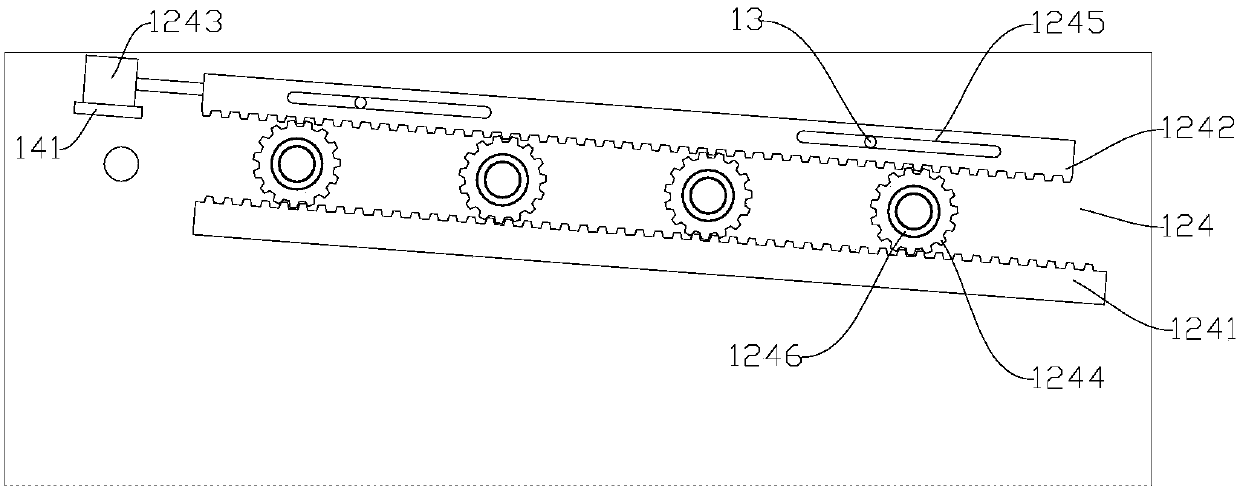

[0032] Such as figure 1 As shown, an ore mining and transporting device includes a box body 1 and a first driving device 2, and the first driving device 2 is used to drive the box body 1 to move to transport the ore to a designated place; the top of the box body 1 is provided with an inlet A material opening 11; a stone crushing mechanism 12 is also provided in the box body 1 . By setting the crushing mechanism 12 inside the box body 1, the ore can be primary crushed when it is loaded into the box body 1 and during transportation, which can save subsequent crushing time and improve work efficiency; at the same time, the large ore can be crushed in advance to avoid There is a problem that the box body 1 is easily da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com