Large vertical type composite ring rolling mill and control method

A compound rolling and vertical technology, which is applied in the direction of rolling mill control device, rolling force/roll gap control, metal rolling, etc., can solve the problems of mechanization, low degree of automation, lack of control model, and lack of automatic control function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

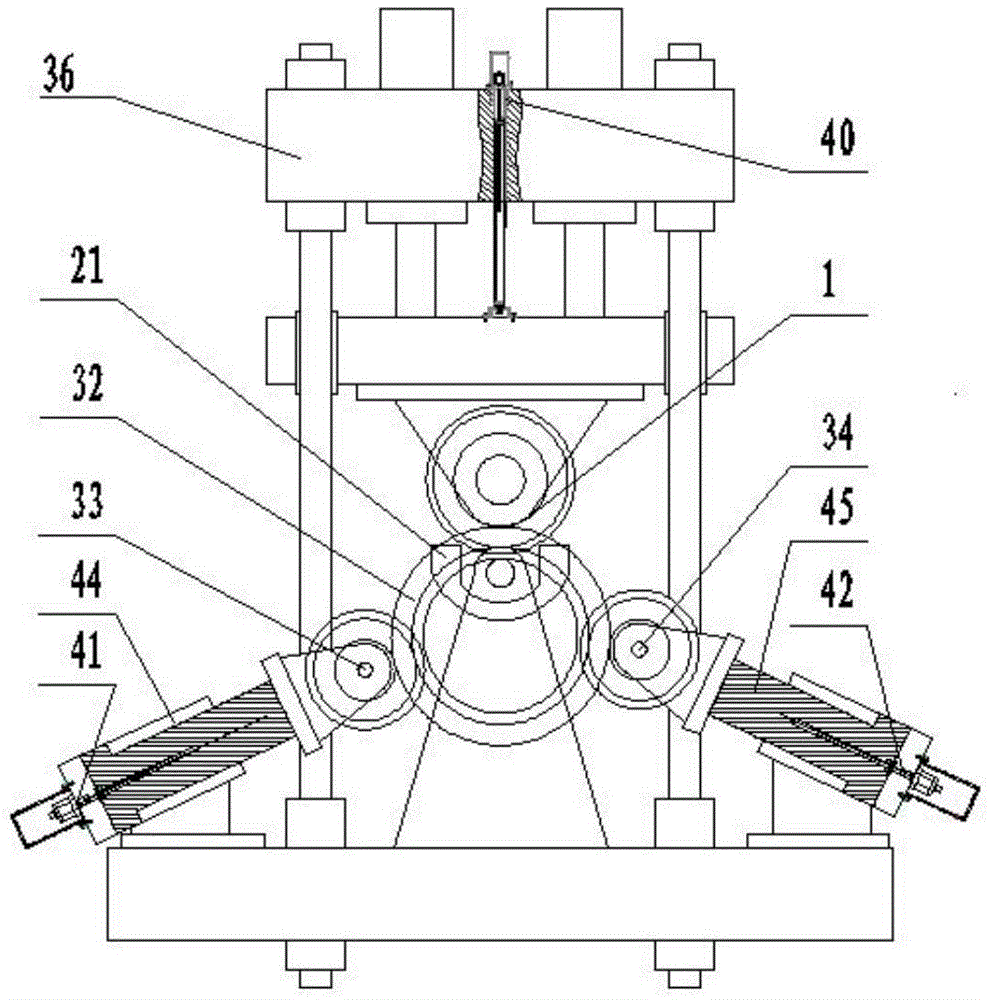

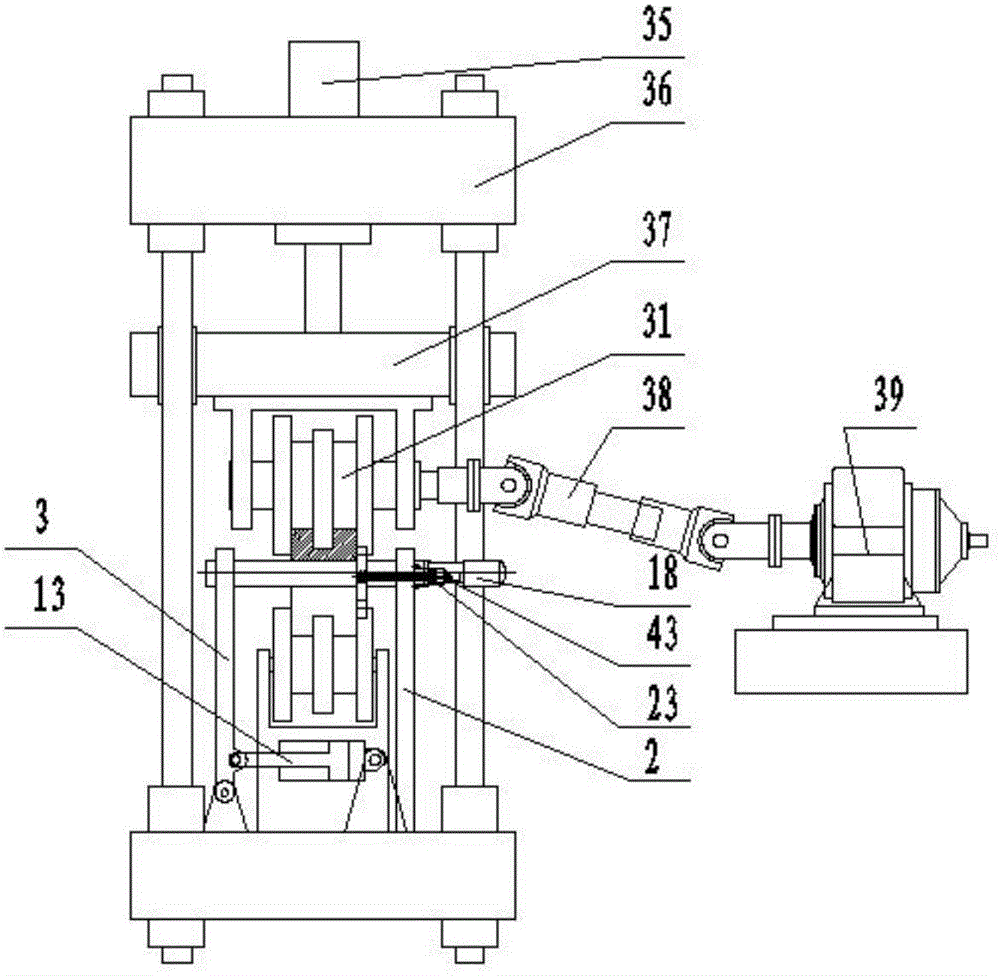

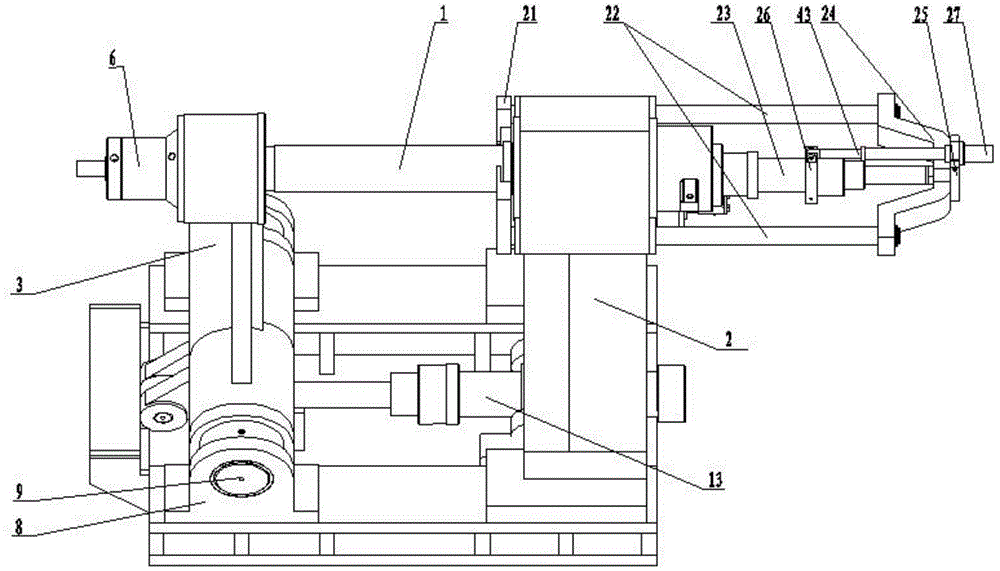

[0031] Such as figure 1 , 2 As shown, a large-scale vertical compound ring rolling machine includes a frame 36, a roller mechanism, a left auxiliary roller mechanism, a right auxiliary roller mechanism, a core roller mechanism and a control device. The roller mechanism includes a rolling wheel 31, a slider 37. Roll oil cylinder 35 and roll motor 39, the output shaft of roll motor 39 is connected with one end of the transmission shaft through universal coupling 38, the other end of the transmission shaft is connected with the rolling wheel 31, and the other end of the transmission shaft is connected with the slider 37, the slide block 37 is connected with the piston rod of the roll oil cylinder 35, the roll oil cylinder 35 is set on the upper beam of the frame 36, the slide block can slide up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com