Solid fuel product

a solid fuel and product technology, applied in the field of solid fuel briquettes, can solve the problems of industrial fuels, especially coal and wood, being susceptible to degradation, and prone to loss of heat value,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

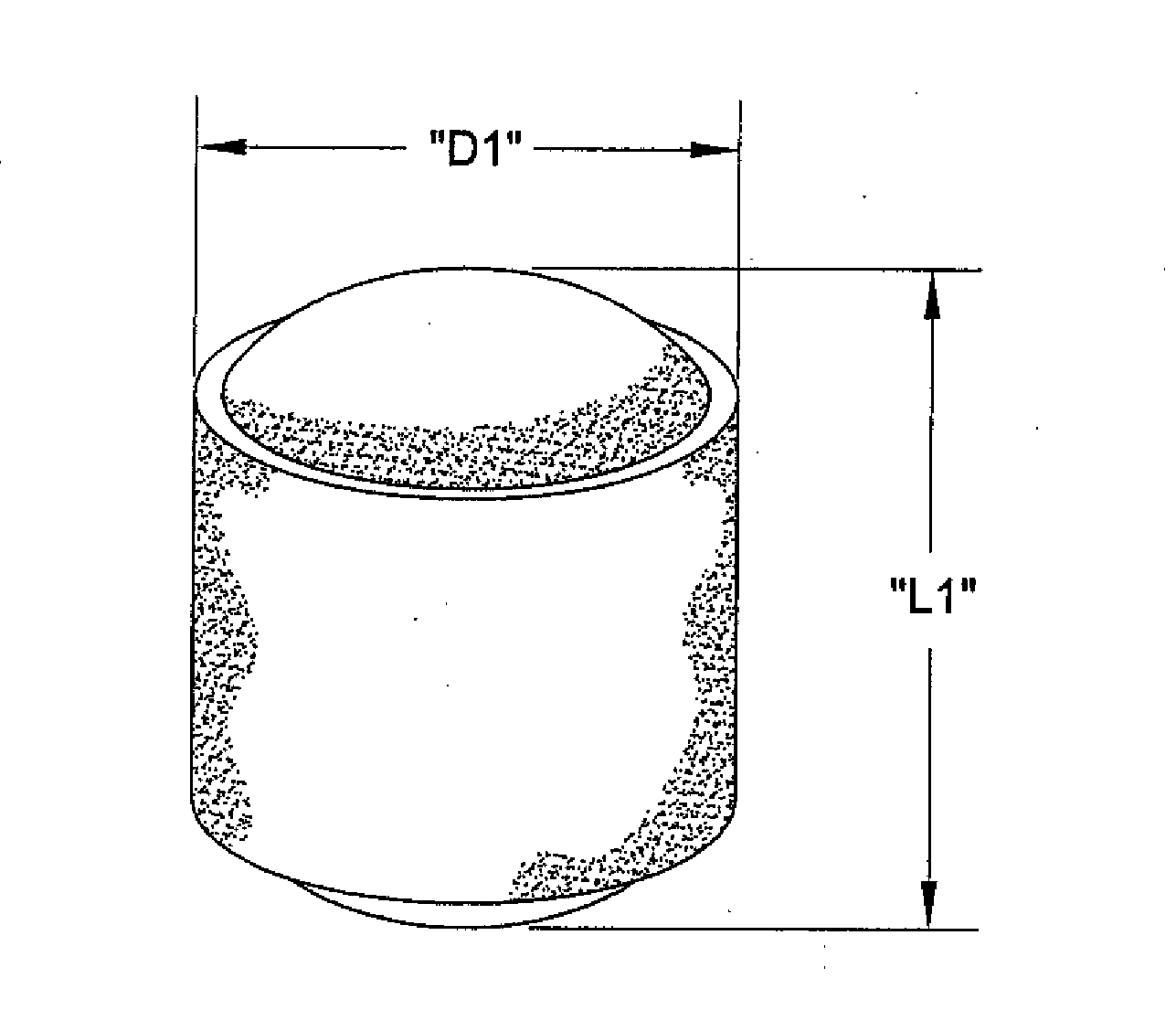

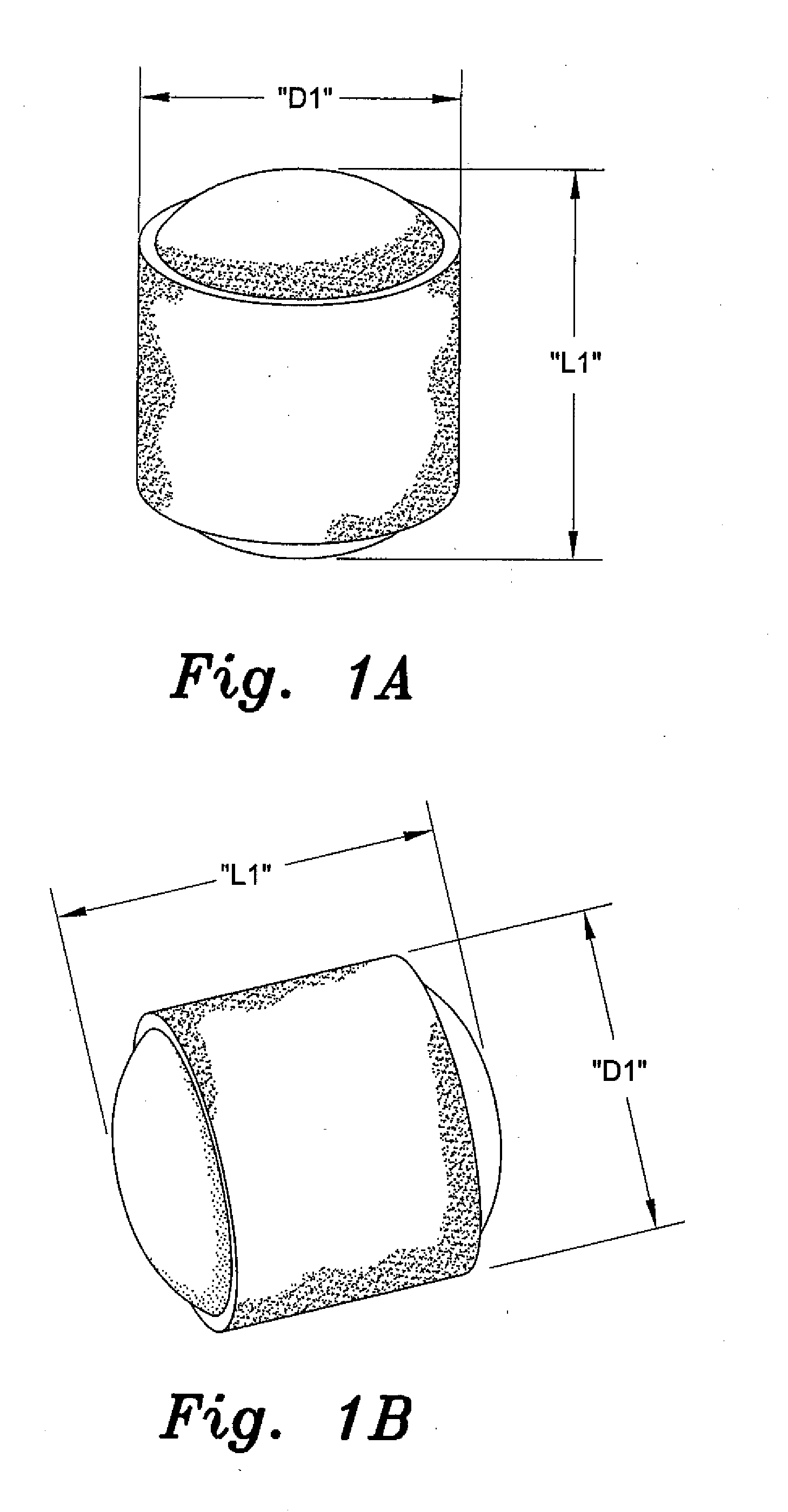

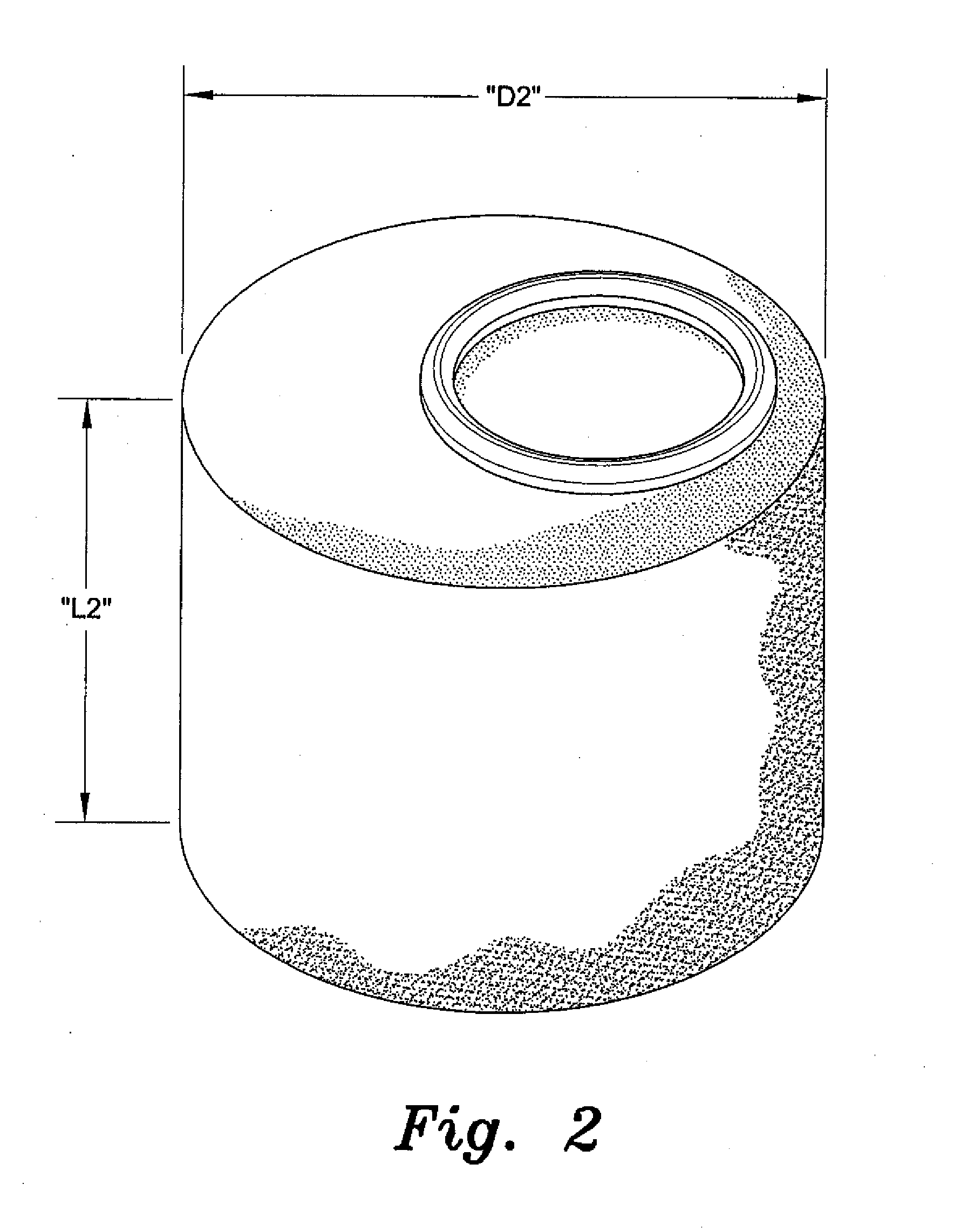

Image

Examples

example 1

[0032]Bituminous coal having a heat value of approximately 9,000 Btu's per pound and a moisture content of 19% was used to prepare a solid fuel product having a heat value of approximately 12,000 Btu's per pound along with a high durability and water resistance, as per an end user's specifications.

[0033]To formulate the desired bituminous coal so as to meet the end user's specifications, the bituminous coal was chemically dried, such as by mixing the bituminous coal with less than 5% by weight of Type 1 Portland cement in the mixer. The bituminous coal was mixed with the Portland cement at high intensity for approximately thirty seconds and then at low intensity for an additional thirty seconds so as to produce the output. The output was discharged into the heater where the discharge was heated to a suitable temperature, such as approximately 100° C. The product was then discharged and stored in the insulated containment bin, where the heat of the insulated containment bin was regul...

example 2

[0037]Sub-bituminous coal having a heat value of 8,500 Btu's per pound and a moisture content of 27.5% was used to prepare a solid fuel product having a reduced moisture content, such as for improved operating efficiency, and a lower dust release in storage and handling systems. The Btu limit was extended to approximately 13,500 Btu's per pound. The solid fuel product was formulated to meet the end user's preference for better water absorption resistance.

[0038]To formulate the desired sub-bituminous coal so as to meet the end user's specifications, the sub-bituminous coal was chemically dried by mixing the sub-bituminous coal with less than 5% by weight of Type 1 Portland cement in the mixer. The sub-bituminous coal was mixed with the Portland cement at high intensity for approximately thirty seconds and then at low intensity for an additional thirty seconds so as to produce the output. The mixer output was then discharged into the heater where the discharge was heated to a suitable...

example 3

[0042]Construction and Demolition (C&D) wood debris having a heat value of 7,100 Btu's per pound, at a moisture content of approximately 15% was used to prepare a solid fuel product having a heat value of approximately 8,600 Btu's per pound. This product was targeted for a small stoker bed boiler that failed to operate with wet biomass handling related problems. Unlike those wood chips, the briquettes formed according to the present teachings showed less than a 1% moisture gain after outdoor storage of more than thirty (30) days, less than a 2.0% moisture gain after a twenty-four hour soak in distilled water, and less than a 0.01% weight loss due to breakage after being dropped from fifty feet, as per an end user's specifications, see Table.

[0043]To prepare the solid fuel product so as to meet the end user's specifications and cost requirements, the locally available C&D wood was screened mechanically and magnetically before passing through a chipper with a ⅜ inch round hole screen....

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com