A kind of nanoscale cement preparation method

A kind of cement preparation, nano-scale technology, applied in the industrial production of nano-scale cement, in the field of nano-scale cement preparation, to achieve the effect of improving compressive strength and low gas permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A nano-scale cement preparation method provided by the present invention, the first step: control moisture: 1. Use ordinary or ultra-fine silicate, aluminate, phosphate, dental cement and other types of quick-drying cement available in the market A kind of cement or oil well cement is used as cement raw material, and it is dried in electric heating drying equipment for later use. Using the optimization method, it is selected to be dried at 120 degrees Celsius for 4 hours, and the water content is less than 3%, so as to ensure that the ball does not stick to the ball during impact.

[0022] 2. Prepare co-ground cement of composite high polymer or fiber: use one of the above-mentioned cements to dry in the same way, and the additive is polyacrylate (PAE); or polyvinyl ester (PVE); or polyvinyl ester (PVE); Vinylidene (PVDC); or ultra-high molecular weight polyethylene fiber, etc. The amount added to the cement is preferably 0.25%-2%; and the corresponding additive is...

Embodiment 2

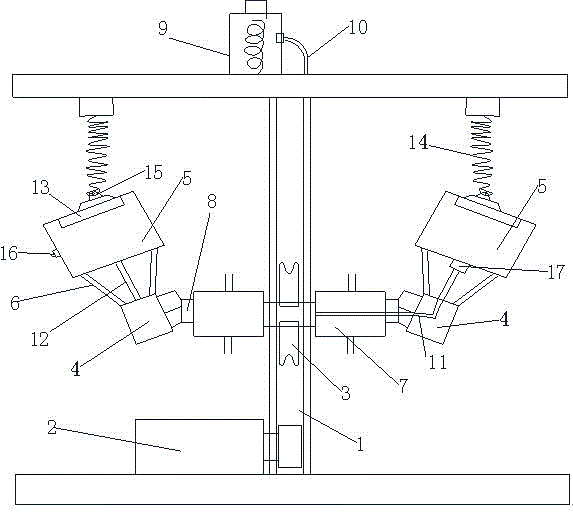

[0034] This embodiment is basically similar to Example 1. Further implementation of the co-ground cement is described. The additive is selected as polypropylene fiber 100G and added to the dried Portland cement 5KG. The ratio of addition is 2%. The propylene fiber is loaded into a 12L type double-tube hanging spring liquid-cooled micro-nano ball mill, 2.5KG per can, 50G polypropylene fiber, 5KG steel balls, the ball-to-material ratio is about 2:1, and the ball hammer pulverization is carried out at 35°C , a total of 600 times per minute hammer mill, 8 hours after taking out. Separate the pellets. After sampling, use a vacuum packaging machine to seal the cement with a double-aluminum composite film and put it into storage. At the same time, the sample was measured by X-ray small-angle scattering method for particle distribution, average particle size and specific surface area. And detect the specific surface area and the strength, permeability and microstructure of ceme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com