Special concrete material and preparation method and application thereof

A concrete and special technology, applied in bridge materials, on-site coagulation pavement, pavement details, etc., can solve the problem of mechanical properties without bending resistance, impact resistance, anti-splitting resistance, slow opening to traffic, slow strength development, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

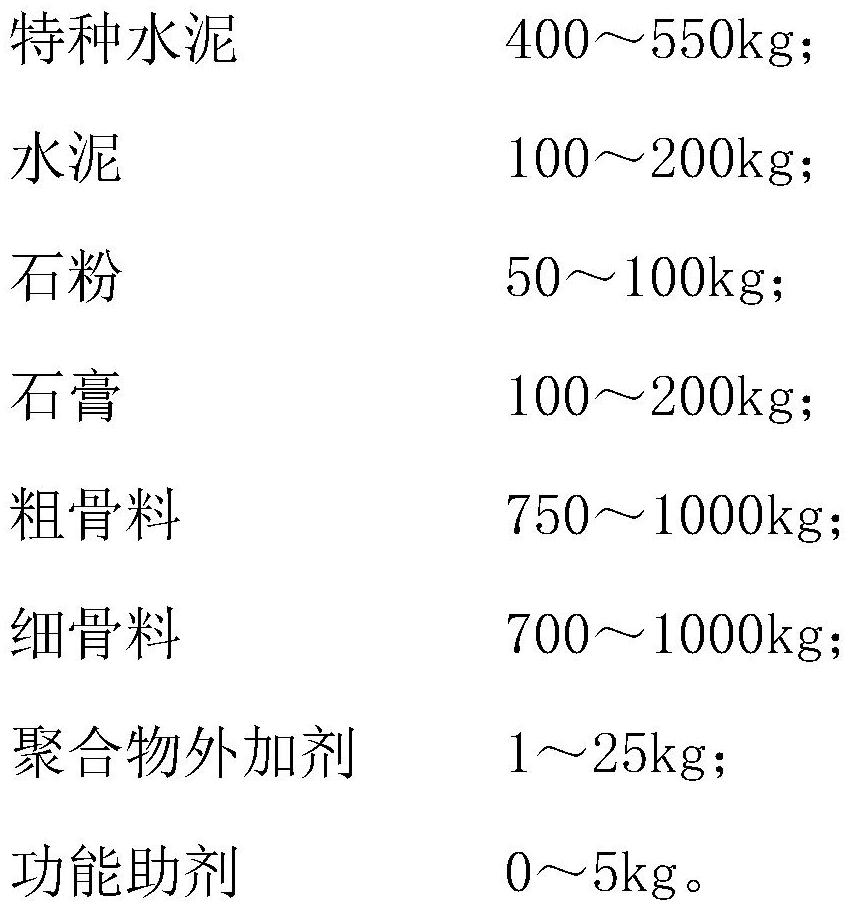

Method used

Image

Examples

Embodiment 1

[0028] A kind of special concrete material, its preparation method is as follows:

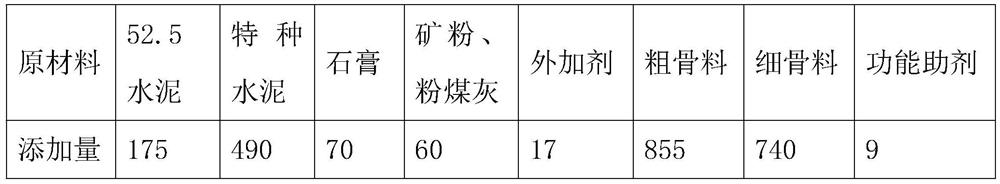

[0029] Table 1. Raw material ratio (unit: kg / m 3 )

[0030]

[0031] Select formula raw material components according to Table 1, wherein, cement is 52.5 grade ordinary Portland cement, special cement is high-strength special cement, gypsum is anhydrite, fly ash, mineral powder is grade II, and fine aggregate modulus is 2.7mm, the particle size of coarse aggregate is 3-16mm, polycarboxylate high-efficiency water reducer, functional additives include retarder, thickener and water-retaining agent, dispersible latex powder, etc. First select raw materials according to the above-mentioned composition and dosage according to the mixing ratio, then use a dry powder mortar mixing system to stir for 3 to 6 minutes to form a homogeneous finished product, and then pass it through a packaging machine to form a bagged final product. When using, add 5-15% water to the dry material, mix the water and dr...

Embodiment 2

[0034] Table 2. Raw material ratio (unit: kg / m 3 )

[0035]

[0036] Select formula raw material components according to Table 2, wherein, cement is 42.5 grade ordinary portland cement, special cement is high-strength special cement, gypsum is anhydrite, fly ash, mineral powder is grade II, fine aggregate modulus is 2.7mm, the particle size of coarse aggregate is 3-16mm, the polycarboxylate is Shanghai Sanrui polycarboxylate high-efficiency superplasticizer, and the functional additives include retarder, thickening and water-retaining agent, which can be dispersed in latex powder, etc. According to the above composition and dosage, select raw materials according to the mixing ratio, and then use a dry powder mortar mixing system to stir for 3 to 6 minutes to form a homogeneous finished product, and then pass through a packaging machine to form a bagged final product. When using, add 5-15% water to the dry material, mix the water and dry material evenly with a special mixer...

Embodiment 3

[0039] Table 3. Raw material ratio (unit: kg / m 3 )

[0040]

[0041] Select formula raw material components according to Table 3, wherein, cement is 42.5 grade ordinary portland cement, special cement is 42.5 special cement, gypsum is anhydrite, fly ash, mineral powder is grade II, fine aggregate modulus is 2.8mm, the particle size of coarse aggregate is 3-16mm, polycarboxylate high-efficiency water reducer, functional additives include retarder, thickener and water-retaining agent, which can be dispersed in latex powder, etc. First select raw materials according to the above-mentioned composition and dosage according to the mixing ratio, then use a dry powder mortar mixing system to stir for 3 to 6 minutes to form a homogeneous finished product, and then pass it through a packaging machine to form a bagged final product. When using, add 5-15% water to the dry material, mix the water and dry material evenly with a special mixer to form finished concrete, and pour the finis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com