Slurry suitable for large-diameter shield tunnel synchronous grouting

A technology of shield tunneling and simultaneous grouting, applied in tunnels, tunnel linings, wellbore linings, etc., can solve the problems of high later strength, short setting time, and rapid early strength growth, etc., and achieves easy quality, low cost, and preparation method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

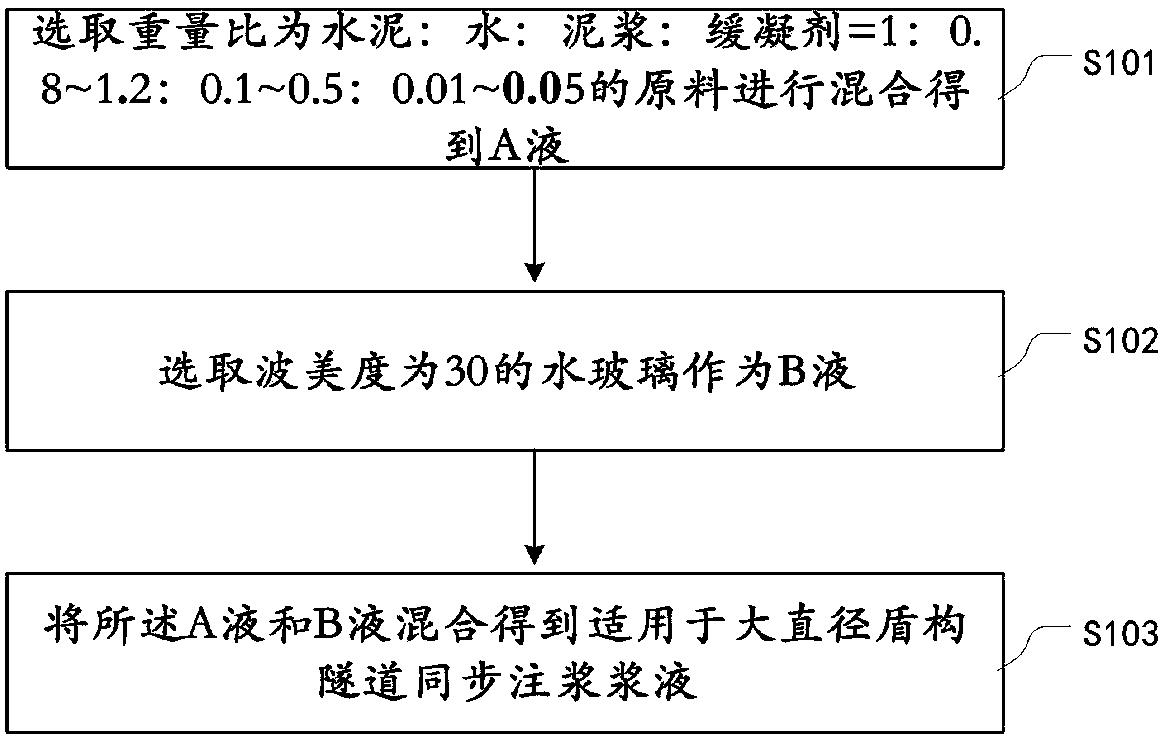

Method used

Image

Examples

Embodiment 1

[0026] In said A liquid, the weight ratio (Kg / m3) of each raw material component 3 ) is: cement: 700; water 630; mud: 180; retarder: 35.

[0027] The bleeding rate of the liquid A is 3.5%, the fluidity is not less than 210mm, the coagulation time after the liquid A and the liquid B are mixed is 18.6s, and the 28d compressive strength is 23.1MPa.

Embodiment 2

[0029] In said A liquid, the weight ratio (Kg / m3) of each raw material component 3 ) is: cement: 650; water 650; mud: 130; retarder: 13.

[0030] The bleeding rate of the liquid A is 4.3%, the fluidity is not less than 240mm, the coagulation time after the liquid A and the liquid B are mixed is 17.3s, and the 28d compressive strength is 22.3MPa.

Embodiment 3

[0032] In said A liquid, the weight ratio (Kg / m3) of each raw material component 3 ) is: cement: 700; water 560; mud: 210; retarder: 14.

[0033] The bleeding rate of the liquid A is 3.1%, the fluidity is not less than 230mm, the coagulation time after the liquid A and the liquid B are mixed is 16.4s, and the 28d compressive strength is 24.5MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com