High-performance polymer repair mortar

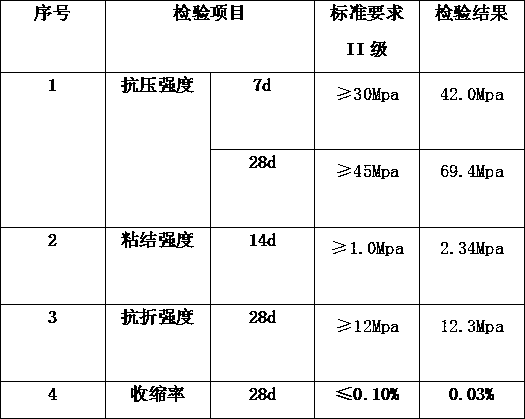

A high-performance polymer, repairing mortar technology, applied in the field of construction engineering materials, can solve the problems of weak bonding, easy cracking, difficult laying, etc., to achieve good construction workability, good freeze-thaw resistance, and strong bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] Example: A high-performance polymer repair mortar, the high-performance polymer repair mortar is composed of the following raw materials by weight percentage: 35 parts of double fast anti-cracking aluminum sulphur cement, 5 parts of cement, 0.15 parts of polybasic acid, Wake 2.5 parts of rubber powder, 0.1 part of cellulose mud, 0.25 parts of lithium carbonate accelerator, 0.3 parts of silicon-magnesium lubricant, 0.07 parts of sodium citrate, 40 parts of water-washed sand, and 16.63 parts of quartz sand.

[0015] When in use: Add water to the mixing machine and add the repair mortar while stirring and continue to stir for 5 minutes. The weight ratio of water: repair mortar is 1:10. Clean the surface of the building substrate, keep it clean and free of impurities, and soak the building with water Apply the mixed repair mortar to the surface of the building substrate evenly with a trowel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com