Preparation and using method of steam-curing alkali-activated cement

A technology of alkali-activated cement and steam curing, which is applied in the field of preparation of alkali-activated cement, and can solve the problems of high cost and no obvious advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail through specific examples below, but the present invention is not limited thereto.

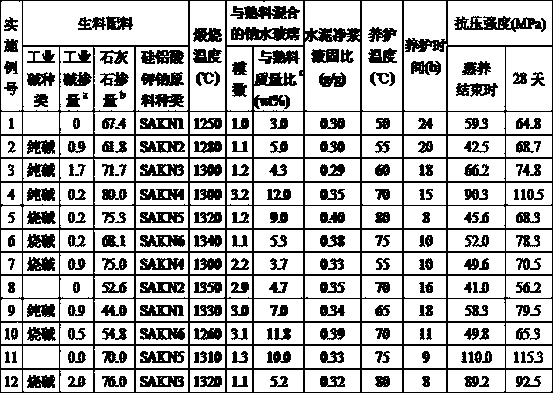

[0014] Prepare soda ash, caustic soda, potassium and sodium aluminosilicate raw materials and limestone, of which there are 6 kinds of potassium and sodium aluminosilicate raw materials, all of which are natural rock mixtures. In the residue after calcination at 1100°C in air, SiO 2 +Al 2 o 3 +Na 2 O+K 2 The mass proportion of O+CaO+MgO is 96~98%, and the rest of the chemical composition is mainly Fe 2 o 3 with TiO 2 . SiO 2 +Al 2 o 3 +Na 2 O+K 2 O+CaO+MgO is calculated as 100%. The chemical composition of the six kinds of potassium aluminosilicate raw materials is shown in Table 1. The content of each component meets the requirements of CaO: 0~5.0%, MgO: 0~2.0%, SiO 2 : 50.0~75.0%, Al 2 o 3 : 15.0~35.0%, Na 2 O+K 2 O: 5.0~11.0%. Mix soda ash or caustic soda with potassium sodium aluminosilicate and limestone in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com