Backfill leveling material and using method thereof

A raw material, the technology of ordinary Portland cement, applied in other household appliances, applications, household appliances, etc., can solve the problems of unfavorable ecological environment protection, a large amount of river sand, unfavorable river protection, etc., and achieves fast foaming speed and heat insulation. Good performance and durability, simple and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A backfill leveling material, comprising the following raw materials in mass percentage: 0.8% foaming agent, 0.4% reinforcing agent, 0.38% anti-cracking filler, and the rest is cement, which includes a mixture of ordinary Portland cement and sulphoaluminate cement, The weight ratio of ordinary Portland cement and sulphoaluminate cement is 8:1.

[0018] The method of using the backfill leveling material, the specific steps are as follows: stir the backfill leveling material, water and ordinary Portland cement evenly, the mass ratio of the backfill leveling material, water and ordinary silicate is 4:80:5, Then cast on site.

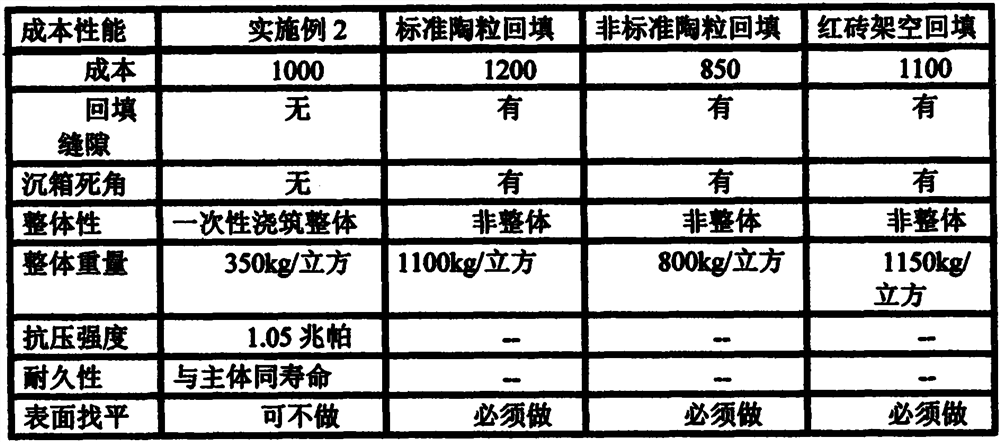

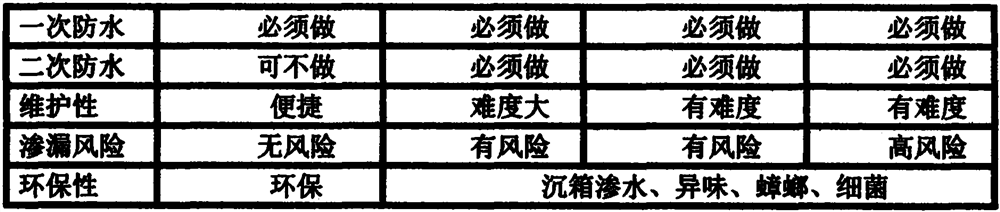

Embodiment 2

[0020] A backfill leveling material, including the following raw materials in mass percentage: 0.92% of animal fat, 0.45% of reinforcing agent, 0.44% of anti-cracking filler, and the rest is cement. The cement includes a mixture of ordinary Portland cement and sulphoaluminate cement, ordinary The weight ratio of Portland cement and sulphoaluminate cement is 9:1. The method of using the backfill leveling material, the specific steps are as follows: stir the backfill leveling material, water and ordinary Portland cement evenly, the mass ratio of the backfill leveling material, water and ordinary silicate is 45:800:62, Then cast on site.

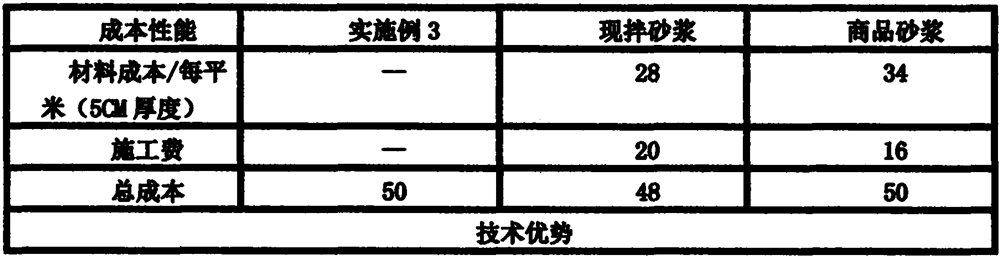

Embodiment 3

[0022] A backfill leveling material, including the following raw materials in mass percentage: 1% animal fat, 0.5% sodium aluminate, 0.5% polypropylene short fiber, and the rest is cement, and the cement includes a mixture of ordinary Portland cement and sulphoaluminate cement , the weight ratio of ordinary Portland cement and sulphoaluminate cement is 10:1.

[0023] The method of using the backfill leveling material, the specific steps are as follows: stir the backfill leveling material, water and ordinary Portland cement evenly, the mass ratio of the backfill leveling material, water and ordinary silicate is 11:160:15, Then cast on site.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com