Graphene oxide modified cellulose-based phase change microcapsule and preparation method thereof

A technology of graphene modification and cellulose, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., to achieve the effect of high coating rate, uniform shape and favorable heat storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing graphene oxide-modified cellulose-based phase-change microcapsules of the present invention is prepared according to the amount of raw materials mentioned above, specifically comprising the following steps:

[0032] (1) Prepare an aqueous solution of emulsifier, add distilled water to sodium lauryl sulfate, Tween-20 and defoamer respectively, and finally stir at 60°C for 20 minutes at a stirring speed of 600-800rpm to obtain an aqueous solution of emulsifier .

[0033] (2) Prepare the ethyl acetate solution of palmitic acid and ethyl cellulose, put the palmitic acid and ethyl cellulose in a container, then add ethyl acetate, stir at 65°C until the palmitic acid and ethyl cellulose are completely dissolved.

[0034] (3) Add the ethyl acetate solution in step (2) into step (1) under stirring at 60-70°C, and mix for 4-6 hours at 600-1000 rpm, at which point the ethyl acetate is completely volatilized, and then After cooling to room temperature, grap...

Embodiment 1

[0037] Step 1, add 0.4g Tween-20, 0.1g sodium lauryl sulfate, 0.1g MO-2170 defoamer to 300mL deionized water, stir at 60°C and 600rpm for 30 minutes to prepare emulsifier solution A.

[0038] Step 2: Add 5g of palmitic acid and 0.5g of ethyl cellulose to 50mL of ethyl acetate, stir at 65°C and 600rpm for 30 minutes until the palmitic acid and ethyl cellulose are completely dissolved to obtain ethyl cellulose and palmitic acid Ethyl acetate solution B.

[0039] Step 3: Add solution B to solution A at 60°C and 600rpm and mix for 4h. At this time, the ethyl acetate is completely volatilized. Cool to room temperature, then add 0.1g graphene oxide and stir for 2h, filter and wash with suction, and vacuum dry at 40°C for 24h , to prepare graphene oxide-modified cellulose-based phase-change microcapsules.

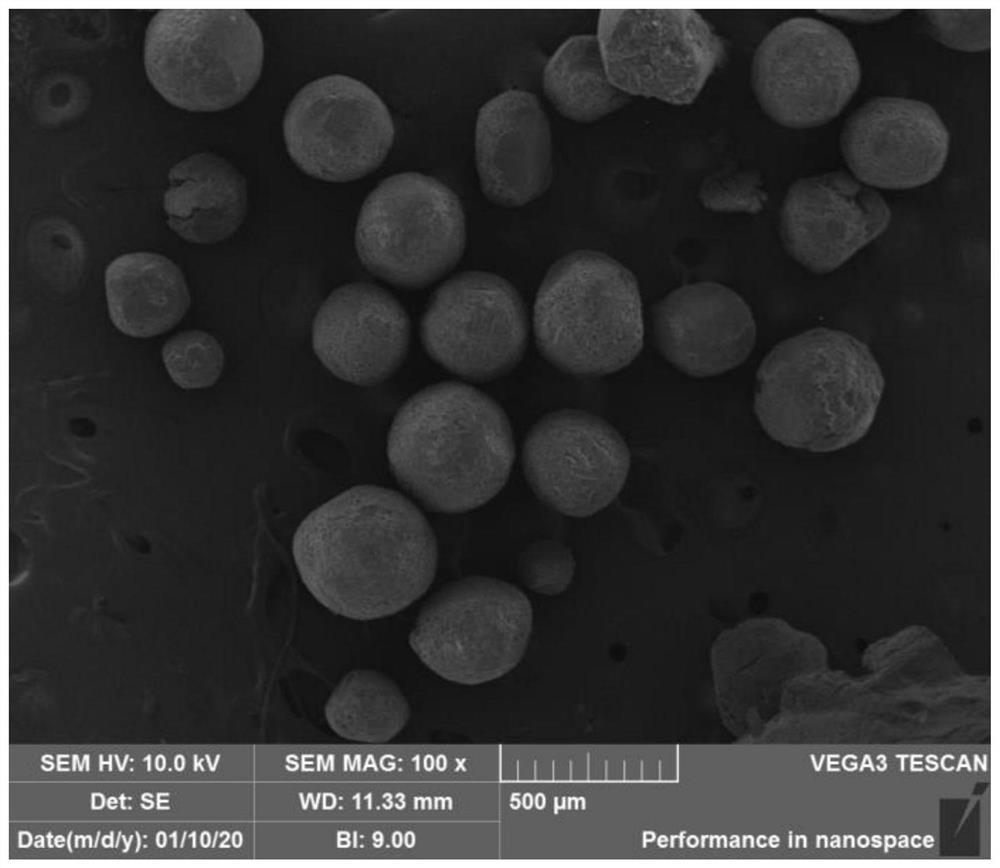

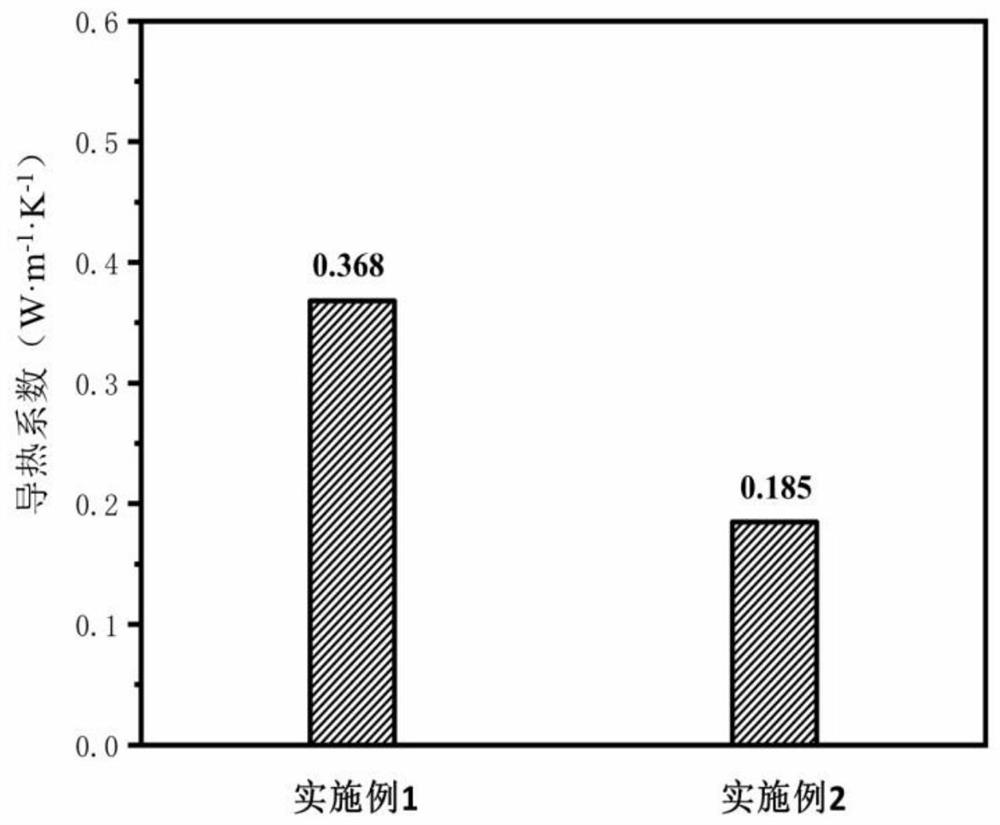

[0040] From figure 1 It can be seen that the phase-change microcapsules obtained in this example are spherical, the ethyl cellulose coating rate is high, the shape is controllab...

Embodiment 2

[0042] Step 1, add 0.4g Tween-20, 0.1g sodium lauryl sulfate, 0.1g MO-2170 defoamer to 300mL deionized water, stir at 60°C and 600rpm for 30 minutes to prepare emulsifier solution A.

[0043] Step 2: Add 5g of palmitic acid and 0.5g of ethyl cellulose to 50mL of ethyl acetate, stir at 65°C and 600rpm for 30 minutes until the palmitic acid and ethyl cellulose are completely dissolved to obtain ethyl cellulose and palmitic acid Ethyl acetate solution B.

[0044]Step 3: Add solution B to solution A at 60°C and 600rpm and mix for 4h. At this time, the ethyl acetate is completely volatilized. Cool to room temperature, then add 0.05g graphene oxide and stir for 2h, filter and wash with suction, and dry in vacuum at 40°C for 24h , prepared graphene oxide-modified cellulose-based phase-change microcapsules.

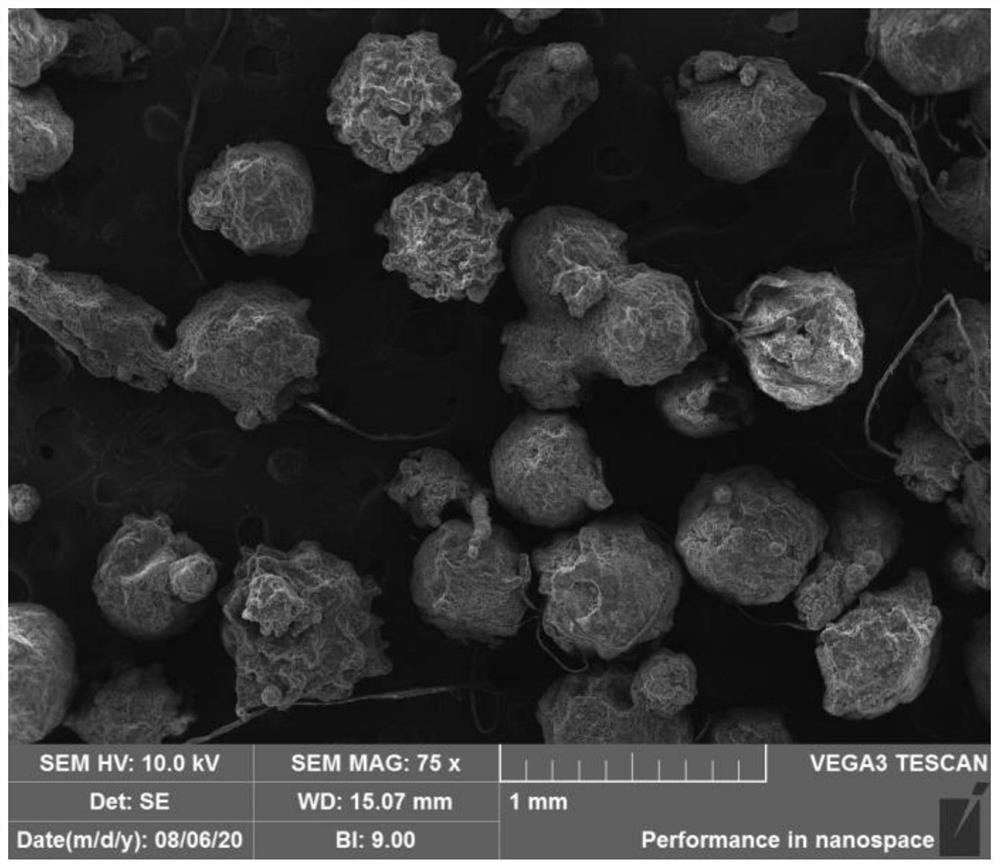

[0045] The particle size of the phase-change microcapsules obtained in this example is also 200-300 μm, the phase-transition temperature is 63.3°C, the latent heat of phase-chan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com