Low-conductivity cooling liquid and preparation method thereof

A cooling liquid and low-conductivity technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as poor stability, and achieve the effects of preventing corrosion, inhibiting hydrolysis, and inhibiting the occurrence of hydrolysis reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

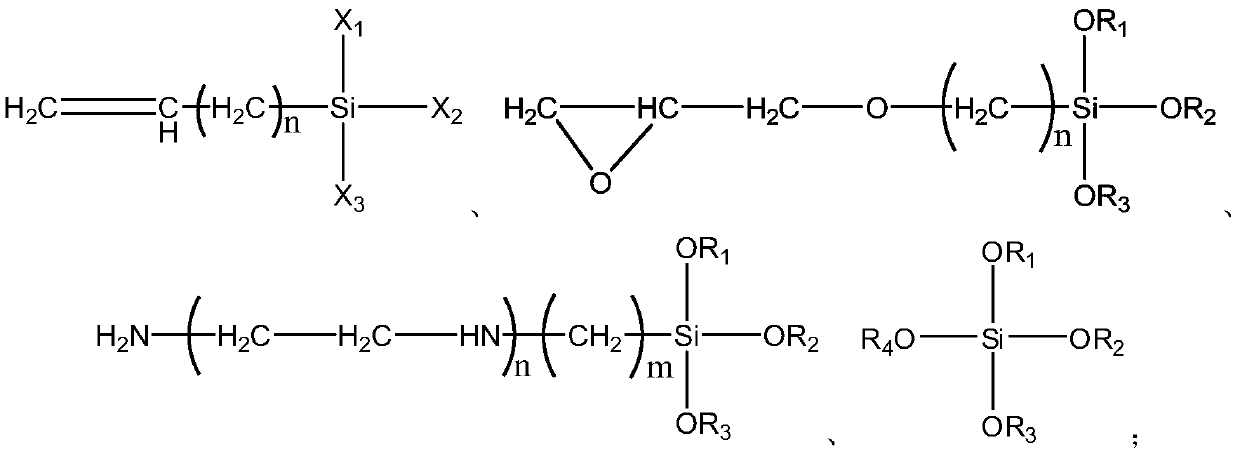

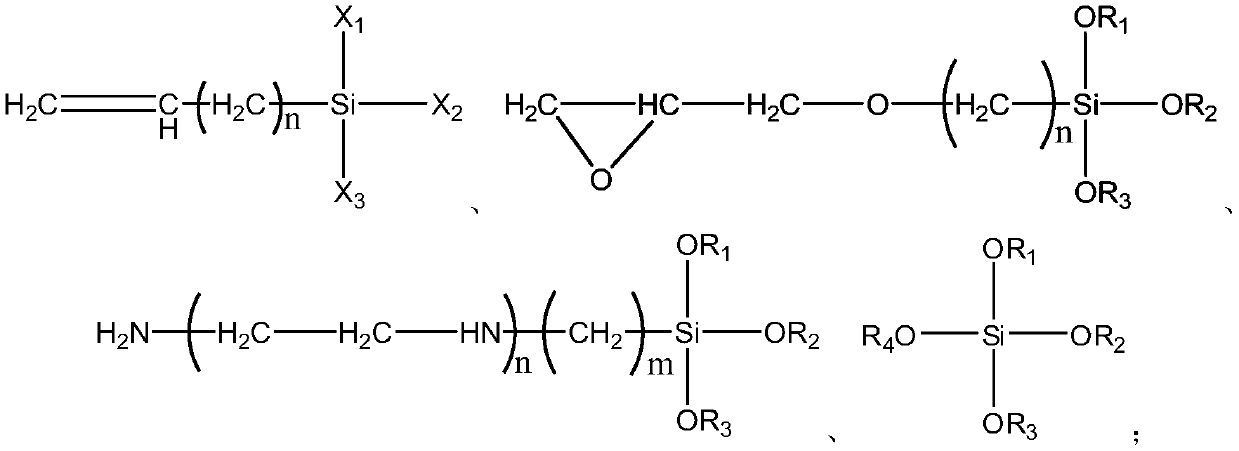

Method used

Image

Examples

Embodiment Construction

[0027] The organosilicon compounds used in the following examples and comparative examples are all products of Dow Corning Co., Ltd., 5-methoxyuracil is a product of Ruierfeng Chemical Co., Ltd., and 4-amino-5-imidazole carboxamide is a product of Shanghai Jiangzhou Chemical Co., Ltd. The company's products, methyl benzotriazole is a product of Nantong Kanghua Chemical Co., Ltd., and N-lauroyl sarcosine is a product of Beijing Bailingwei Technology Co., Ltd.

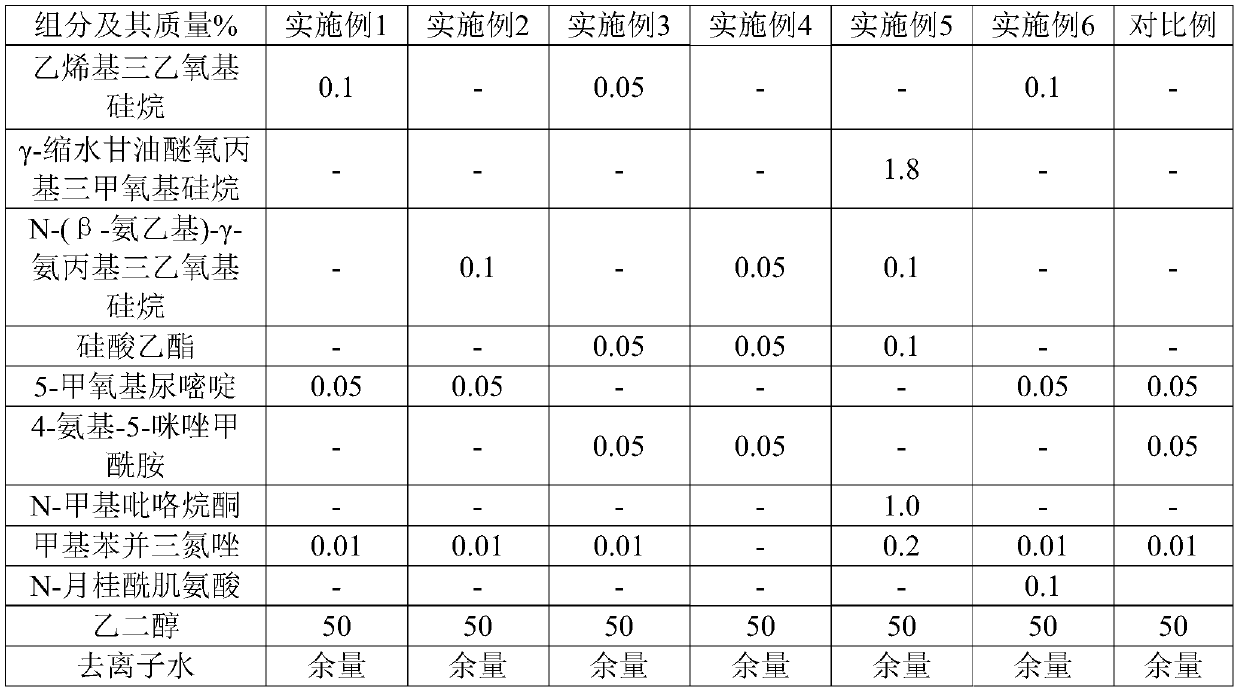

[0028] Each component and its mass percentage in Examples 1-6 and Comparative Examples are shown in Table 1.

[0029] Table 1

[0030]

[0031] The preparation method of the cooling liquid described in Examples 1-6 is: mix the organosilicon compound, the nitrogen-containing compound and the azole compound evenly, then add it to the glycol, stir at room temperature for more than 20 minutes, and finally add deionized water and stir evenly , to obtain a low-conductivity coolant.

[0032] The preparation method of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com