Mica tape, high in ventilation performance and with little glue, suitable for pure epoxy VPI insulating resin and preparation method thereof

A technology of less glue mica tape and insulating resin, used in mica, insulators, inorganic insulators, etc., can solve the problem of extending the shelf life of pure epoxy VPI insulating resin, to ensure storage stability, improve electrical performance, and ensure long-term storage. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

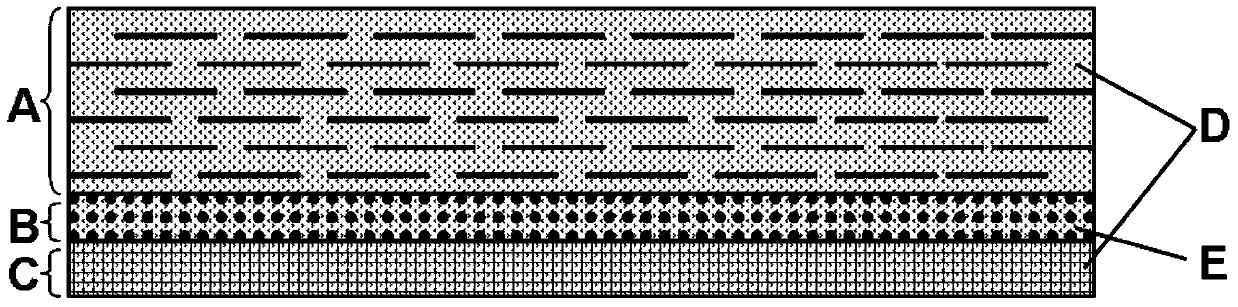

[0046] The present embodiment provides a kind of highly gas-permeable little glue mica tape that is applicable to pure epoxy VPI insulating resin, and its structure is as follows figure 1 shown. In this mica tape, the powder adhesive is carboxyl-terminated polyester resin (the number average molecular weight Mn is 20000, and the acid value is 85mg KOH / g); the mica paper layer A is non-calcined large-scale muscovite paper with a thickness of 0.11mm, which is breathable The sex is 172s / 100cm 3 , the mass per unit area is 181g / m 2 ;The reinforcing material layer C is electrical grade non-alkali glass fiber cloth, the thickness is 0.032mm, and the mass per unit area is 23.1g / m 2 . Latent epoxy curing accelerator D is zinc naphthenate.

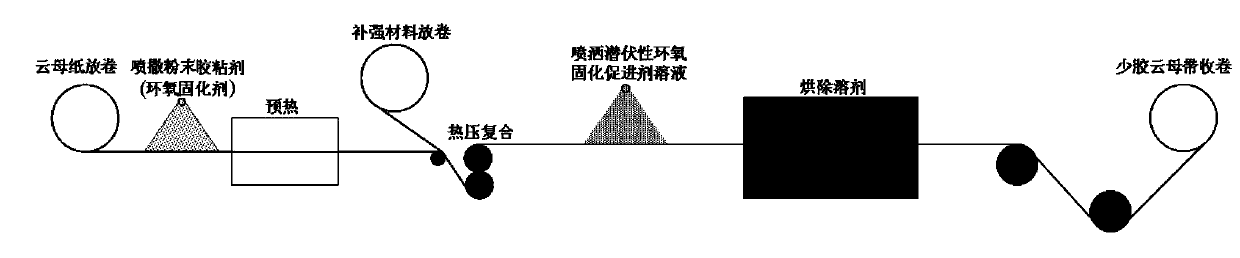

[0047] The preparation method of the highly air-permeable less-adhesive mica tape is as follows:

[0048] (1) Carboxyl-terminated polyester resin was pulverized at 0°C at low temperature and sieved to obtain a powder adhesive with a particle s...

Embodiment 2

[0056] The present embodiment provides a kind of highly gas-permeable little glue mica tape that is applicable to pure epoxy VPI insulating resin, and its structure is as follows figure 1 shown. In the mica tape, the powder adhesive is composed of carboxyl-terminated polyester resin (number average molecular weight Mn is 30000, acid value is 75mg KOH / g) and Nadic acid anhydride with an anhydride equivalent of 170 in a weight ratio of 1:1; the mica paper layer A It is non-calcined large-scale muscovite paper with a thickness of 0.11mm and an air permeability of 165s / 100cm 3 , the mass per unit area is 178g / m 2 ;The reinforcing material layer C is electrical grade non-alkali glass fiber cloth, the thickness is 0.035mm, and the mass per unit area is 28.3g / m 2 . The latent epoxy curing accelerator D is composed of zinc naphthenate and chromium acetylacetonate in a weight ratio of 2:1.

[0057] The preparation method of the highly air-permeable less-adhesive mica tape is as fol...

Embodiment 3

[0066] The present embodiment provides a kind of highly gas-permeable little glue mica tape that is applicable to pure epoxy VPI insulating resin, and its structure is as follows figure 1 shown. In the mica tape, the powder adhesive is composed of carboxyl-terminated polyester resin (number average molecular weight Mn is 28000, acid value is 58 mg KOH / g) and trimellitic anhydride with an acid value of 870 and a melting point of 167 °C in a weight ratio of 1:1; mica Paper layer A is non-calcined large scale muscovite paper with a thickness of 0.10mm and an air permeability of 155s / 100cm 3 , the mass per unit area is 162g / m 2 ; The reinforcing material layer C is an electrical grade non-alkali glass fiber cloth with a thickness of 0.032mm and a mass per unit area of 23.3g / m2. The latent epoxy curing accelerator D is composed of zinc neodecanoate and aluminum acetylacetonate in a weight ratio of 1:1.

[0067] The preparation method of the highly air-permeable less-adhesive m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com