Emulsion-type accelerator special for sprayed concrete

A shotcrete and emulsion type technology, applied in the field of building materials, can solve the problems of decreased concrete strength and durability, high alkali content, and more dust, and achieve the improvement of the retention rate of compressive strength, the improvement of specific surface area, and the durability. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

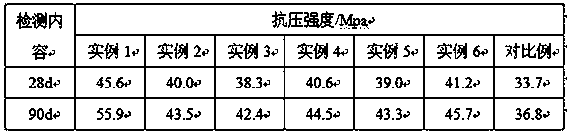

Examples

example 1

[0020] In parts by weight, take 30 parts of sepiolite successively, 100 parts of dilute hydrochloric acid with a mass fraction of 10%, first mix the sepiolite and dilute hydrochloric acid into the hydrothermal kettle, then seal the hydrothermal kettle, and heat the hydrothermal kettle at a temperature of 150 ℃, the pressure is 2.7MPa, the stirring speed is 500r / min, after hydrothermal stirring reaction for 5h, the hydrothermal kettle is opened, the pressure is released to normal pressure, the material is discharged, and the filter cake is obtained by suction filtration, and the filter cake is washed with deionized water. Cake 5 times, then transfer the washed filter cake to an oven, and dry it to a constant weight at a temperature of 110°C to obtain a dry filter cake, then transfer the resulting dried filter cake to a tube furnace, and dry it at a temperature of 260°C Under the condition of ℃, roast for 3 hours, and discharge the material to obtain activated sepiolite; in parts...

example 2

[0022]In parts by weight, successively take 40 parts of graphene oxide, 200 parts of water, 10 parts of sodium polystyrene sulfonate, and 10 parts of octadecylamine, first mix graphene oxide and water into a beaker, and then Move the beaker into an ultrasonic disperser, and ultrasonically disperse for 60 minutes at an ultrasonic frequency of 60 kHz to obtain a graphene oxide dispersion, then add the obtained graphene oxide dispersion and octadecylamine into a three-necked flask, and transfer the three-necked flask to To the digital display speed measuring constant temperature magnetic stirrer, under the condition of temperature of 85 ℃ and rotating speed of 600r / min, heat and stir for 5 hours, then add sodium polystyrene sulfonate into the three-necked flask under constant temperature stirring, and continue stirring at constant temperature After reacting for 2 hours, filter to obtain the filter residue, and wash the filter residue 5 times with deionized water, then transfer the...

example 3

[0024] In parts by weight, successively take 40 parts of graphene oxide, 200 parts of water, 10 parts of sodium polystyrene sulfonate, and 10 parts of octadecylamine, first mix graphene oxide and water into a beaker, and then Move the beaker into an ultrasonic disperser, and ultrasonically disperse for 60 minutes at an ultrasonic frequency of 60 kHz to obtain a graphene oxide dispersion, then add the obtained graphene oxide dispersion and octadecylamine into a three-necked flask, and transfer the three-necked flask to To the digital display speed measuring constant temperature magnetic stirrer, under the condition of temperature of 85 ℃ and rotating speed of 600r / min, heat and stir for 5 hours, then add sodium polystyrene sulfonate into the three-necked flask under constant temperature stirring, and continue stirring at constant temperature After reacting for 2 hours, filter to obtain the filter residue, and wash the filter residue 5 times with deionized water, then transfer th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com