Phosphate-modified porous starch quantitative embedding tea polyphenol compound and preparation method and application thereof

A technology of porous starch and phosphate ester, applied in application, food science, tobacco and other directions, can solve the problems of loss of scavenging free radicals in cigarette smoke, discount of efficacy in application, inability to play its role, etc., to achieve good antioxidant capacity, The effect of simple addition method and guaranteed storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

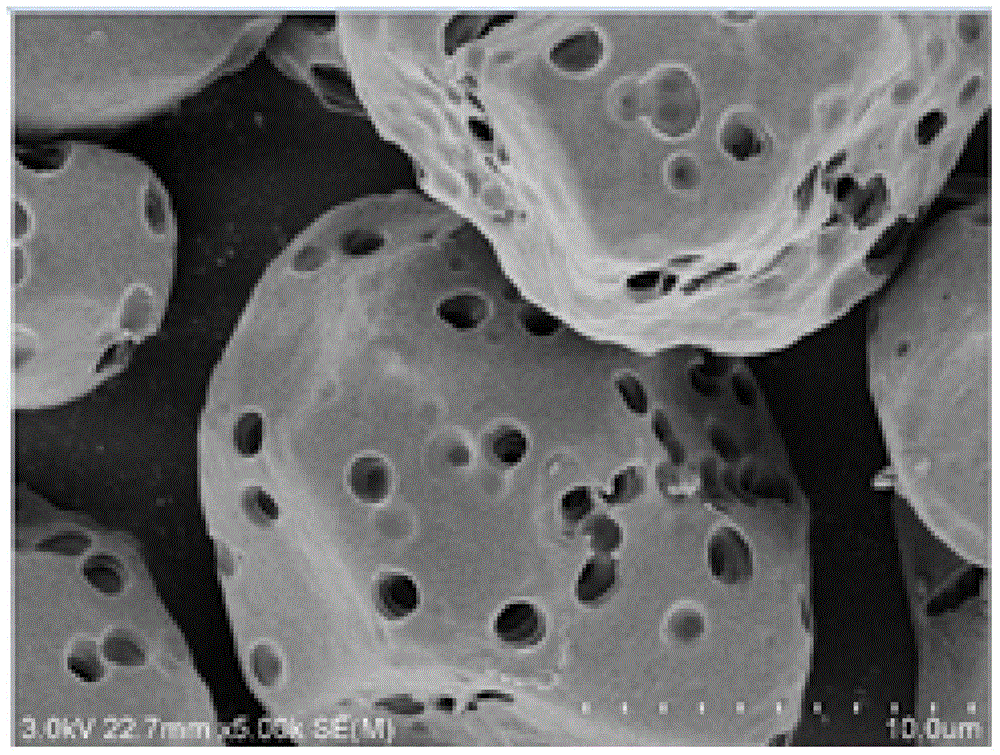

[0028] 1. Preparation of corn porous starch

[0029] The raw corn starch is made into starch milk with a concentration of 20% (m / v) from a pH 5.5 phosphate buffer solution, stirred and preheated in a constant temperature magnetic stirrer at 55°C for 10 minutes, and then a compound enzyme with a mass of 1% of the raw corn starch is added (Glucoamylase: α-amylase = 1:3, w / w) for enzymolysis, stirred and reacted at 55°C for 12 hours, then added 1mol / L NaOH solution to adjust the pH value to 10.0, filtered and washed the filter cake in Dried in a drying oven at 50°C to constant weight, crushed and passed through a 100-mesh sieve to obtain corn porous starch.

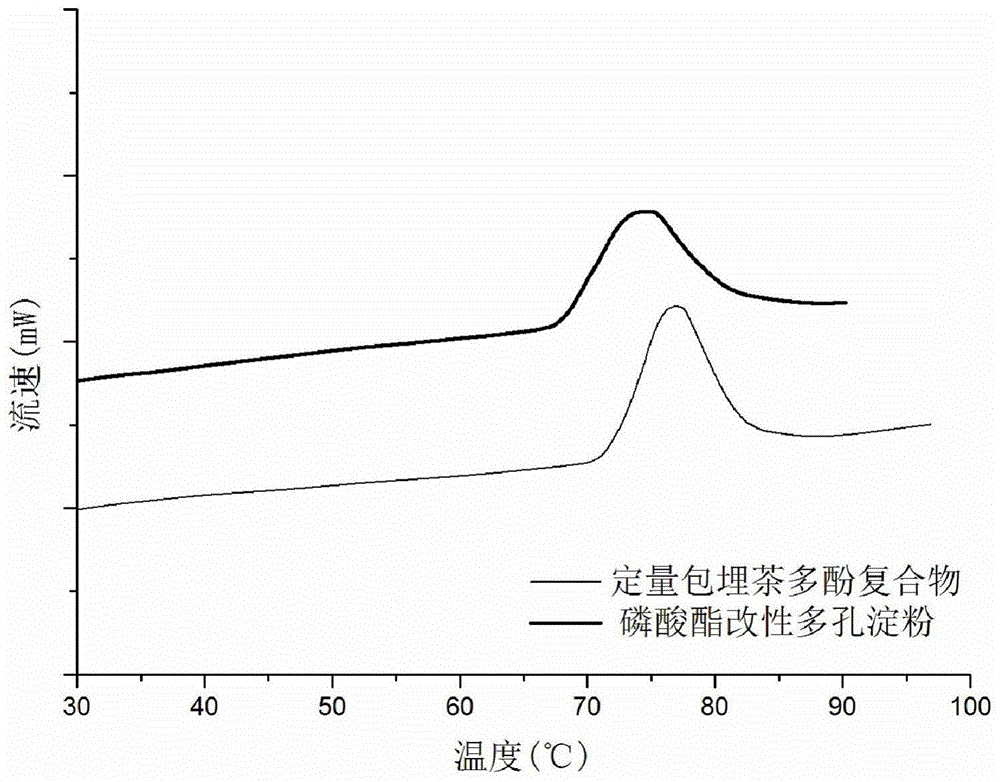

[0030] 2. Preparation of phosphate ester modified porous starch

[0031] First prepare a sodium tripolyphosphate solution with a concentration of 5% (m / v), then adjust the pH value to 6.0 with a phosphoric acid solution, then add corn porous starch to the sodium tripolyphosphate solution to prepare a concentration of 40% (m...

Embodiment 2

[0038] 1. Preparation of corn porous starch

[0039] With embodiment 1.

[0040] 2. Preparation of phosphate ester modified porous starch

[0041] Prepare a sodium tripolyphosphate solution with a concentration of 7% (m / v), then adjust the pH value to 6.0 with phosphoric acid solution, then add corn porous starch to the sodium tripolyphosphate solution to prepare a starch with a concentration of 40% (m / v) Milk, stirred for 30 minutes and suction filtered, the obtained filter cake was soaked and washed with 95% ethanol, and suction filtered again, the filter cake was dried at 40°C to a moisture content of 5-10%, the reaction temperature was controlled at 140°C for 150 minutes, and crushed through 100 mesh Sieve to obtain phosphate ester modified porous starch with a degree of substitution of 0.078.

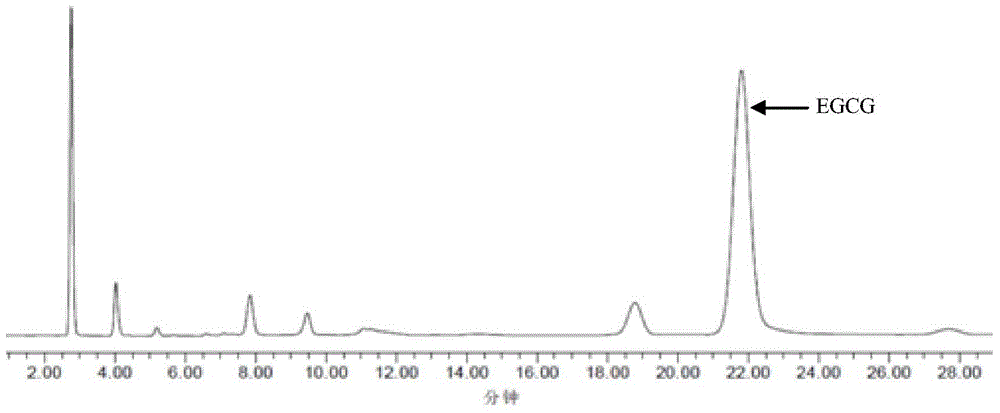

[0042] 3. Preparation of phosphate-modified porous starch quantitatively entrapped tea polyphenol compound

[0043] Weigh 4.5g of tea polyphenols and prepare 1000mL of a solutio...

Embodiment 3

[0045] 1. Preparation of corn porous starch

[0046] With embodiment 1.

[0047] 2. Preparation of phosphate ester modified porous starch

[0048] Prepare a sodium tripolyphosphate solution with a concentration of 3% (m / v), then adjust the pH value to 6.0 with a phosphoric acid solution, then add corn porous starch to the sodium tripolyphosphate solution to prepare a starch with a concentration of 40% (m / v) Milk, stirred for 30 minutes and suction filtered, the obtained filter cake was soaked and washed with 95% ethanol, and suction filtered again, the filter cake was dried at 40°C to a moisture content of 5-10%, the reaction temperature was controlled at 140°C for 150 minutes, and crushed through 100 mesh Sieve to obtain phosphate ester modified porous starch with a degree of substitution of 0.036.

[0049] 3. Preparation of phosphate-modified porous starch quantitatively entrapped tea polyphenol compound

[0050] Weigh 4.0g of tea polyphenols and prepare 1000mL of a solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com