Low temperature curable bottom filling adhesive with heat transfer function and preparation method thereof

A technology of underfill glue and thermally conductive filler, which is applied in the direction of chemical instruments and methods, heat exchange materials, adhesives, etc., can solve the problems of low thermal conductivity, low thermal expansion coefficient, and low shrinkage rate of underfill glue, and achieve high adhesion Strength, excellent heat dissipation performance, and mechanical shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

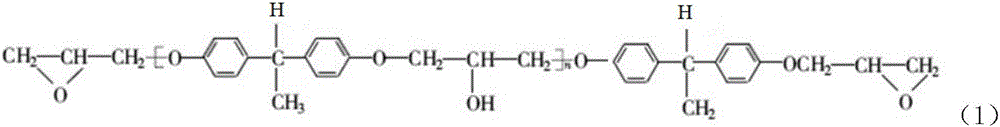

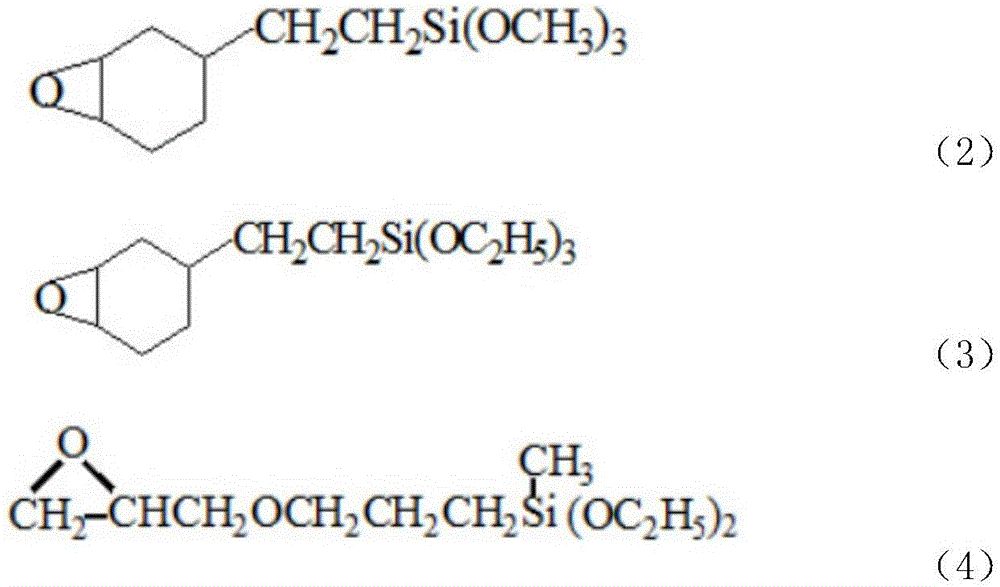

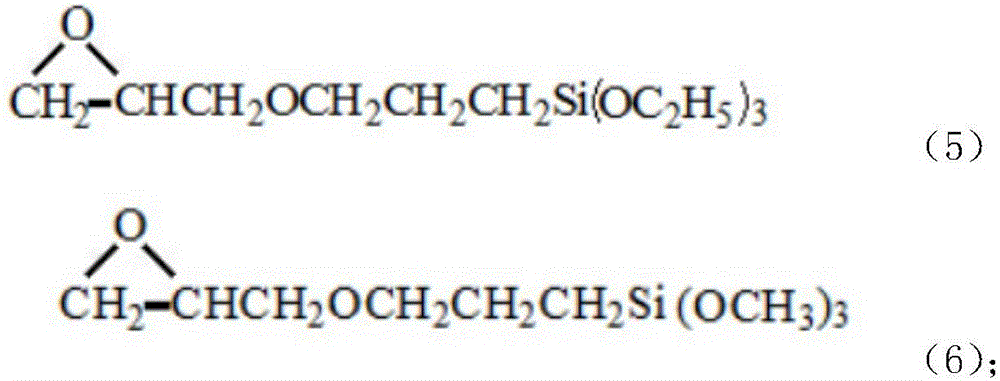

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a preparation and application process of a low-temperature curing underfill with heat conduction function. The preparation method of the underfill includes the following steps:

[0038] (1) Add γ-glycidyl etheroxypropyl trimethoxysilane: 4.6 parts in ethanol solvent, adjust the pH value to 3.2 with oxalic acid, and after hydrolysis reaction at room temperature for 60 minutes, add spherical alumina 180 with a particle size of 1.5 μm Parts, 410 parts of spherical alumina of 45 μm, kept the system temperature at 50°C for 4 hours, then filtered, washed with toluene, and dried in vacuum at 60°C for 24 hours;

[0039] (2) Weigh 90 parts of bisphenol E diglycidyl ether, 10 parts of bisphenol F diglycidyl ether, 15 parts of trimethylolpropane triglycidyl ether, 14 parts of Kane MX125 and 6 parts of polyvinyl alcohol were added to the reaction kettle, the stirring speed was 450r / min, the temperature of the system was heated to 50°C, and stirred for 70 m...

Embodiment 2

[0043] This embodiment provides a preparation and application process of a low-temperature curing underfill with heat conduction function. The preparation method of the underfill includes the following steps:

[0044] (1) Add β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane: 4.2 parts in the ethanol solvent, adjust the pH value to 4 with oxalic acid, and after 40 minutes of hydrolysis at room temperature, add a particle size of 0.8 165 parts of spherical alumina of μm, 390 parts of spherical alumina of 40 μm, keep the system temperature at 40°C for 4.5h, filter, wash with toluene, and dry in vacuum at 60°C for 24h;

[0045] (2) Weigh 70 parts of bisphenol E diglycidyl ether, 30 parts of polybutadiene epoxy resin, 10 parts of glycidyl caprylate, 8 parts of Kane MX153, 7 copies of Kane Add MX154, 11 parts of sodium alkylsulfonate, and 4 parts of phenylethyl alcohol oleate into the reaction kettle, stir at 600r / min, heat the system to 45°C, and stir for 60 minutes to obtain a homo...

Embodiment 3

[0049] This embodiment provides a preparation and application process of a low-temperature curing underfill with heat conduction function. The preparation method of the underfill includes the following steps:

[0050] (1) Add 3.2 parts of β-(3,4-epoxycyclohexyl)ethyltriethoxysilane to the ethanol solvent, adjust the pH value to 4 with oxalic acid, and after hydrolysis reaction at room temperature for 45 minutes, add a particle size of 130 parts of 0.5 μm spherical alumina, 320 parts of 35 μm spherical alumina, maintain the system temperature at 45°C for 3 hours, filter, wash with toluene, and dry in vacuum at 60°C for 24 hours;

[0051] (2) Weigh 85 parts of bisphenol E diglycidyl ether, 15 parts of bisphenol A diglycidyl ether, 25 parts of cresyl glycidyl ether, 13 parts of Kane MX170, 16 parts of sodium polyacrylate, and 8 parts of GPES type defoamer were added to the reaction kettle, the stirring speed was 300r / min, the temperature of the heating system was 50°C, and stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com