Polyaspartic acid ester resin, preparation method, and anticorrosive paint and preparation method thereof

A technology of aspartic acid ester and anti-corrosion coating, which is applied in the direction of polyurea/polyurethane coating, anti-corrosion coating, coating, etc., and can solve the problems that affect the coating's corrosion resistance, easy flocculation, poor dispersion and compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] Preparation method reference example 1 of aminosilane modified graphene oxide

[0061] Add 1.5 parts by weight of graphene oxide to 500 parts by weight of ethanol aqueous solution (mixed with 30 parts by weight of deionized water and 470 parts by weight of absolute ethanol), heat up to 60°C, stir thoroughly for 30 minutes, and then add 1300 parts by weight of aminosilane coupling agent Ethanol solution (14 parts by weight of aminosilane coupling agent KH550 dispersed in 1286 parts by weight of absolute ethanol), after heating up to 78°C, heat-preserved and refluxed for 12 hours, cooled to room temperature, left to stand, and centrifuged to separate the precipitate with absolute ethanol After washing once, wash twice with acetone, and finally dry in vacuum at 50° C. for 10 h, and then it is ready.

[0062] Preparation method reference example 2 of aminosilane modified graphene oxide

[0063] Add 1.5 parts by weight of graphene oxide to 600 parts by weight of methanol aq...

Embodiment 1~3

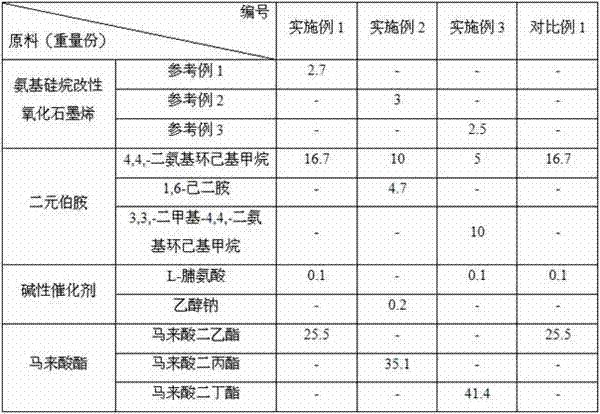

[0067] Polyaspartic acid ester resin embodiment 1~3 raw material components and proportioning ratio are shown in Table 1:

[0068] Table 1 Raw material components and proportions of polyaspartic acid ester resin examples 1-3

[0069]

[0070] Note: "-" in the table means not added.

Embodiment 1

[0072] According to Table 1, the raw material components and proportions in Example 1, mix and stir aminosilane-modified graphene oxide, binary primary amine and basic catalyst, and after heating up to 60°C, add maleic acid ester dropwise for 30 minutes After the dropwise addition, continue to raise the temperature to 100°C, and keep it warm for 11 hours. The conversion rate of the amine value measured by JIS K7327 method is 97.00%. Stop heating and cool to room temperature to obtain polyaspartic acid ester resin 1.

[0073] After testing, the obtained polyaspartic acid ester resin 1 was centrifuged at a high speed of 4000 r / min for 30 min, and no black precipitate was precipitated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com