One coat paint prepared by organic and inorganic compound emulsion and preparation method thereof

A compound type, emulsion technology, applied in the direction of coating, etc., can solve the problems affecting the appearance of the wall surface, wall surface efflorescence, leak primer, etc., and achieve good thermal stability, good film-forming property, and good adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

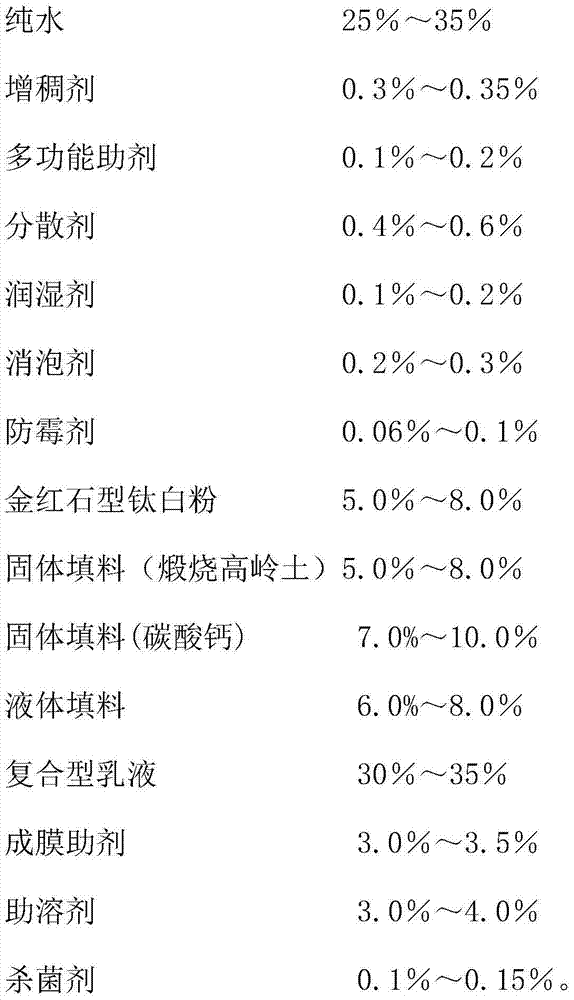

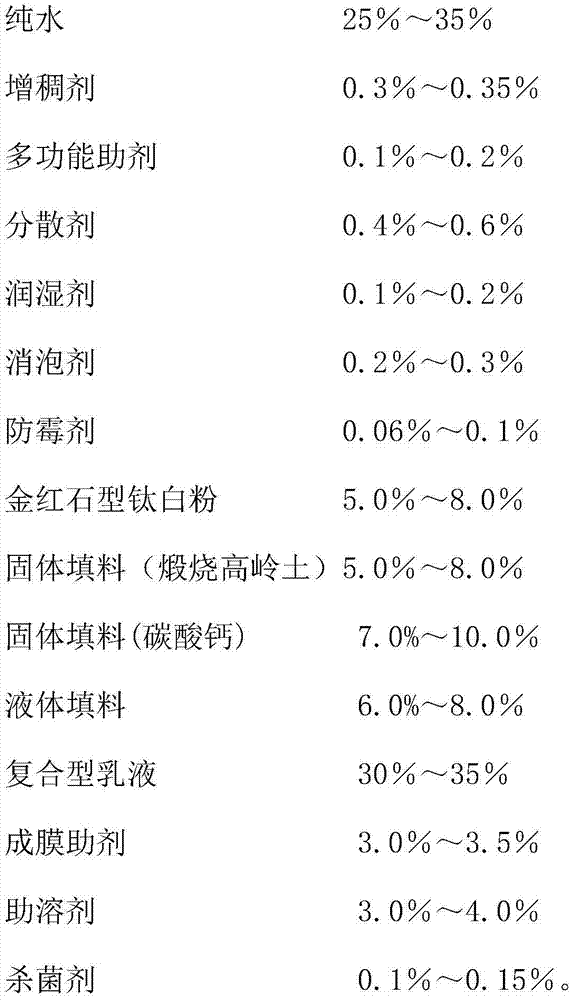

[0035] Preparation steps of the product of the present invention (the following are weight percentages):

[0036] A) Add 29.85% pure water to the reaction kettle, add 0.32% hydroxyethyl cellulose (such as: 250HBR) and 0.15% multifunctional additives (such as: organic amine AMP-95) while stirring,

[0037] B) After the cellulose is completely dissolved, add 0.4% dispersant (such as ammonium polycarboxylate GA40), 0.1% wetting agent (such as: nonylphenol polyoxyethylene ether), 0.15% defoamer ( Such as: mineral oil CF1988) and 0.06% antifungal agent (such as: n-octylisothiazolinone antifungal agent ROCIMA TM 363), after stirring and dispersing at room temperature for 15 minutes,

[0038] C) Add 5.0% titanium dioxide (such as: rutile titanium dioxide 902), 8.0% filler (such as: 2500 mesh calcined kaolin) and 9.0% filler (such as: 1000 mesh calcium carbonate), high-speed stirring for 20 minutes fineness After passing (≤60um),

[0039] D) Then add 8.0% liquid filler (such as: po...

Embodiment 2

[0050] Preparation steps of the product of the present invention (the following are weight percentages):

[0051] A) Add 27.85% pure water to the reaction kettle, add 0.3% hydroxyethyl cellulose (such as: 250HBR) and 0.1% multifunctional additives (such as: organic amine AMP-95) while stirring,

[0052] B) After the cellulose is completely dissolved, add 0.6% dispersant (such as: ammonium polycarboxylate 5027), 0.1% wetting agent (such as: nonylphenol polyoxyethylene ether), 0.15% defoamer ( Such as: mineral oil WO2380) and 0.1% antifungal agent (such as: n-octylisothiazolinone antifungal agent ROCIMA TM 363), after stirring and dispersing at room temperature for 15 minutes,

[0053] C) Add 8.0% titanium dioxide (such as: rutile titanium dioxide 902), 5.0% filler (such as: 2500 mesh calcined kaolin) and 8.0% filler (such as: 1000 mesh calcium carbonate), high-speed stirring for 20 minutes fineness After passing (≤60um),

[0054] D) Then add 7.0% liquid filler (such as: poly...

Embodiment 3

[0060] Preparation steps of the product of the present invention (the following are weight percentages):

[0061] A) Add 33.12% pure water to the reaction kettle, add 0.35% hydroxyethyl cellulose (such as: 250HBR) and 0.2% multifunctional additives (such as: organic amine AMP-95) while stirring,

[0062] B) After the cellulose is completely dissolved, add 0.5% dispersant (such as: polycarboxylate ammonium salt GA40), 0.15% wetting agent (such as: nonylphenol polyoxyethylene ether), 0.2% defoamer ( Such as: mineral oil CF1988) and 0.08% antifungal agent (such as: n-octylisothiazolinone antifungal agent ROCIMA TM 363), after stirring and dispersing at room temperature for 15 minutes,

[0063] C) Add 7.0% titanium dioxide (such as: rutile titanium dioxide 902), 6.0% filler (such as: 2500 mesh calcined kaolin) and 10.0% filler (such as: 1000 mesh calcium carbonate), high-speed stirring for 20 minutes After passing (≤60um),

[0064] D) Then add 6.0% liquid filler (such as: polys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com