Rubber modified asphalt waterproof coating material, preparation method and uses thereof

A technology of asphalt waterproof coating and rubber modification, which is applied in asphalt coatings, chemical instruments and methods, roofs using flexible materials, etc. Achieve the effect of ensuring storage stability, reducing high temperature viscosity, and reducing the difficulty of emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

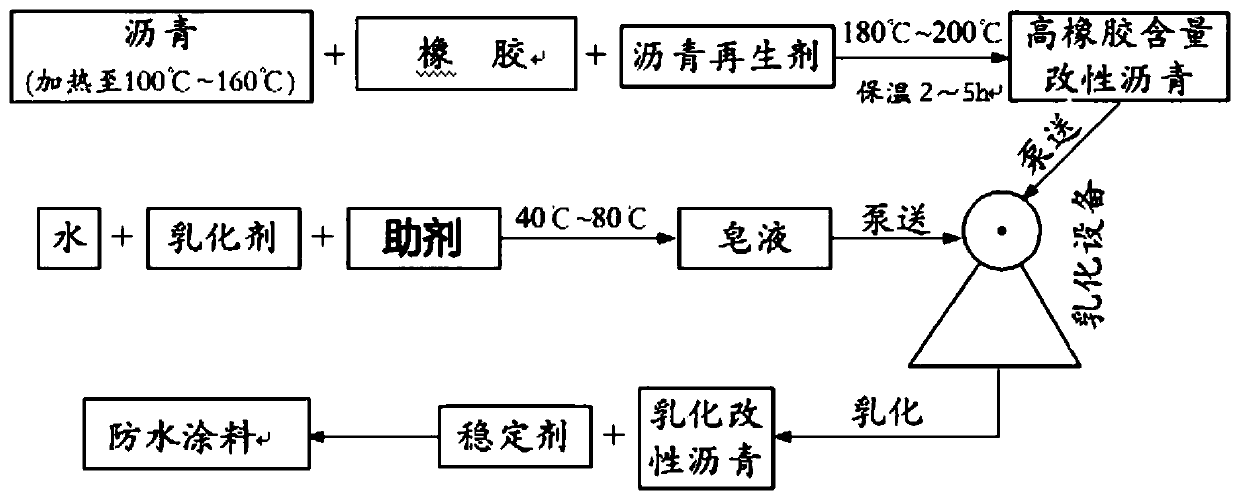

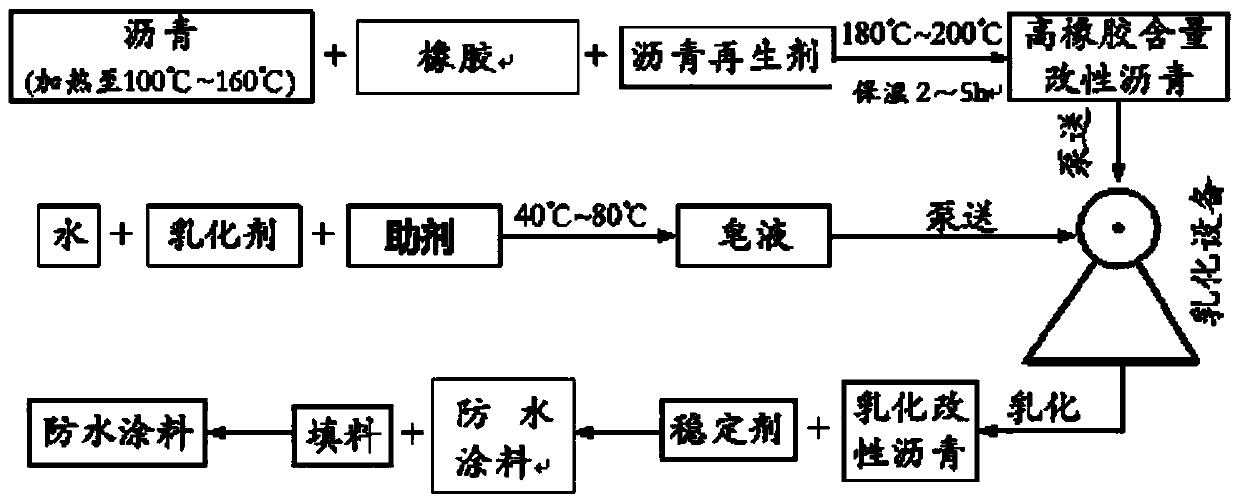

[0045] figure 1 For the preparation process of the waterproof coating without adding fillers, the specific preparation process is as follows:

[0046] One: Preparation of high rubber content modified asphalt;

[0047] First, heat the asphalt to 100°C-160°C, then add rubber and asphalt regenerant, heat up, and modify at a constant temperature within the range of 180°C-200°C for 2-5 hours to obtain modified asphalt;

[0048] Two: Soap preparation;

[0049] Mix and stir water and emulsifier evenly, raise the temperature to 40°C-80°C to make soap liquid, and adjust the pH value to 9-13;

[0050] Three: Preparation of emulsified modified asphalt;

[0051] The prepared modified asphalt and soap liquid are pumped to the emulsification equipment at the same time, and emulsified by the emulsification equipment to obtain emulsified modified asphalt;

[0052] Four: add stabilizer;

[0053] Add a stabilizer to the prepared emulsified modified asphalt, adjust the pH value, and stir ev...

Embodiment 1

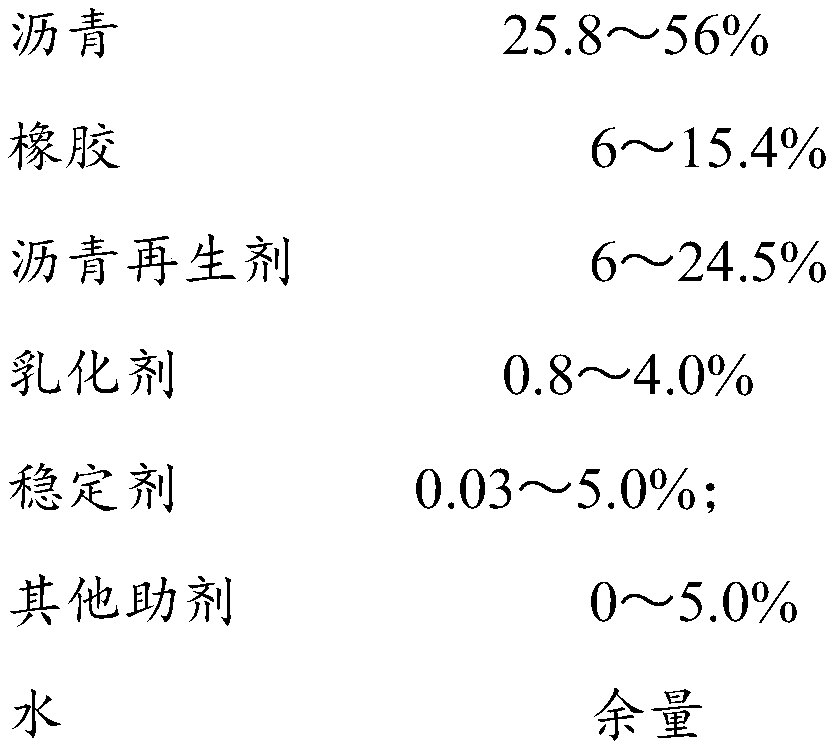

[0088] A rubber-modified asphalt waterproof paint, comprising the following components in weight percentage:

[0089] Petroleum Bitumen No. 110: 33%

[0090] SBS Rubber: 14%

[0091] Asphalt regenerant: 18%

[0092] Water: 30.7%

[0093] Emulsifier: 3%

[0094] Hydroxyethylcellulose: 1%

[0095] Acid: 0.3%.

[0096] Its preparation process is as follows:

[0097] One: Preparation of high rubber content modified asphalt;

[0098] First heat the asphalt to 100°C, then add rubber and asphalt regenerant, heat up, and modify at a constant temperature within the range of 200°C for 3 hours to obtain modified asphalt;

[0099] Two: Soap preparation;

[0100] Mix and stir water, emulsifier, and thickener evenly, raise the temperature to 80°C, adjust the pH value between 9-13, and prepare soap liquid;

[0101] Three: Preparation of emulsified modified asphalt;

[0102] The prepared modified asphalt and soap liquid are pumped to the emulsification equipment at the same time, an...

Embodiment 2

[0134] A rubber-modified asphalt waterproof paint, comprising the following components in weight percentage:

[0135] Petroleum Bitumen No. 90: 40%

[0136] SIS Rubber: 14%

[0137] Asphalt regenerant: 10%

[0138] Water: 30.5%

[0139] Emulsifier: 2.5%

[0140] Carboxymethylcellulose: 1.5%

[0141] Acid: 1.5%.

[0142] The preparation method is the same as in Example 1.

[0143] According to the method requirements of GB / T 16777-2008 "Experimental Methods of Building Waterproof Coatings", the product is tested. Test results of the prepared product: the solid content of the prepared waterproof coating is 67%; the water absorption rate of the waterproof coating after drying is 6.3%, the heat resistance is 90°C, the low temperature is -22°C (2h without cracks), and the bonding strength 0.58MPa, the stress relaxation is 10.2% (and does not separate from the bonding surface), the crack bridging ability is 1.5mm, and the seam deformation ability is 6500 cycles without damage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| brittleness temperature | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com