Amine-free waterproof emulsion, preparing method thereof and waterproof coating containing amine-free waterproof emulsion

A technology of waterproof emulsion and emulsifier, applied in the direction of coating, can solve problems such as unenvironmental protection, and achieve the effect of ensuring stability, improving tensile strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

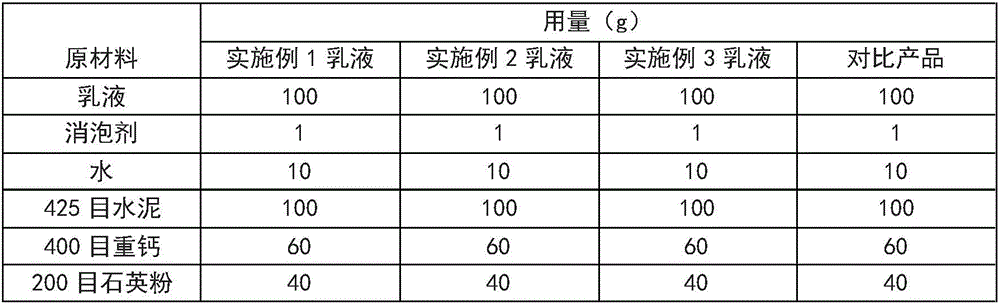

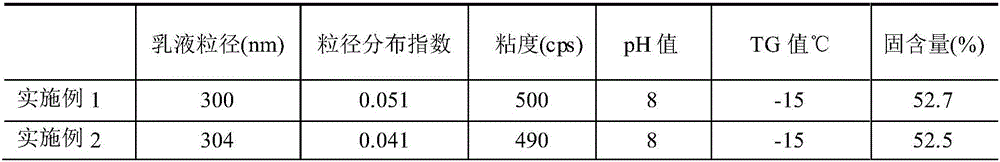

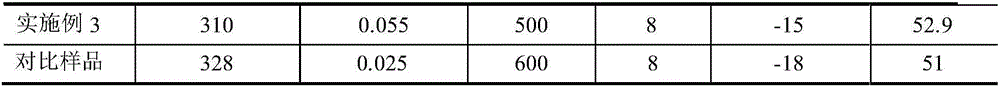

Examples

Embodiment 1

[0029] Amine-free waterproof emulsion, in parts by weight, includes the following components: 43.18 parts of deionized water, 0.07 parts of sodium bicarbonate, 0.1 part of isomeric tridecanol polyoxyethylene ether TO-8, unsaturated allyl alkyl 0.9 parts of ammonium sulfate SR-10, 0.2 parts of potassium persulfate, 0.2 parts of vinyltriethoxysilane, 0.4 parts of SIPOMER PAM100, 37 parts of butyl acrylate, 13.5 parts of styrene, 0.3 parts of allyloxy hydroxysulfonate sodium 2.4 parts of hydroxyethyl acrylate, 1 part of butyl methacrylate, 0.1 part of dodecyl mercaptan, 0.1 part of defoamer, 0.1 part of preservative, and 0.45 part of liquid caustic soda.

Embodiment 2

[0031] Amine-free waterproof emulsion, in parts by weight, includes the following components: 43.18 parts of deionized water, 0.07 parts of sodium bicarbonate, 0.1 part of nonylphenol ethoxylate NE-10, unsaturated allyl alkyl ammonium sulfate 0.9 parts of SR-20, 0.2 parts of potassium persulfate, 0.2 parts of vinyltriethoxysilane, 0.4 parts of SIPOMER PAM100, 37 parts of butyl acrylate, 13.5 parts of styrene, 0.3 parts of allyloxy hydroxysulfonate sodium, 2.4 parts of hydroxyethyl acrylate, 1 part of butyl methacrylate, 0.1 part of dodecyl mercaptan, 0.1 part of defoamer, 0.1 part of preservative, and 0.45 part of liquid caustic soda.

Embodiment 3

[0033]Amine-free waterproof emulsion, in parts by weight, includes the following components: 43.18 parts of deionized water, 0.07 parts of sodium bicarbonate, 0.1 part of nonylphenol ethoxylate NE-10, unsaturated allyl alkyl ammonium sulfate 0.9 parts of SR-20, 0.2 parts of potassium persulfate, 0.2 parts of vinyltriethoxysilane, 0.4 parts of PAM, 37 parts of butyl acrylate, 13.6 parts of styrene, 0.3 parts of sodium allyloxyhydroxysulfonate, acrylic acid 2.4 parts of hydroxypropyl ester, 1 part of butyl methacrylate, 0.1 part of dodecyl mercaptan, 0.1 part of defoamer, 0.1 part of preservative, and 0.45 part of liquid caustic soda.

[0034] The above-mentioned amine-free waterproof emulsion can be prepared by a traditional or existing preparation process, and a more optimized preparation process adopts the method of the present invention, as follows:

[0035] A. Raw material preparation: divide the reactive emulsifier into the first reactive emulsifier and the second reactive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com