Working fluid composition for refrigerator, refrigeration oil, and method for producing same

一种工作流体、冷冻机油的技术,应用在润滑组合物、化学仪器和方法、石油工业等方向,能够解决温室效应强等问题,达到吸附性高、减少填充量、电绝缘性及稳定性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

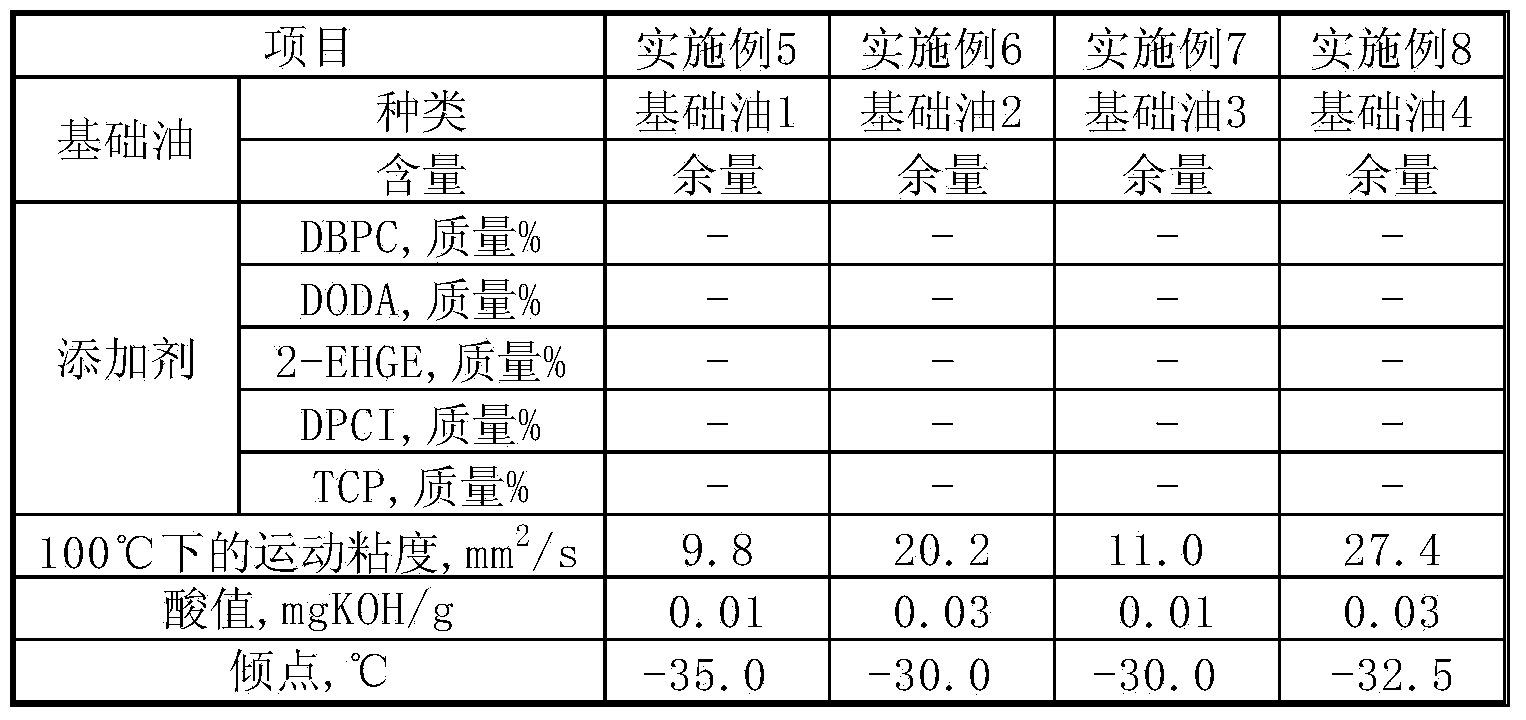

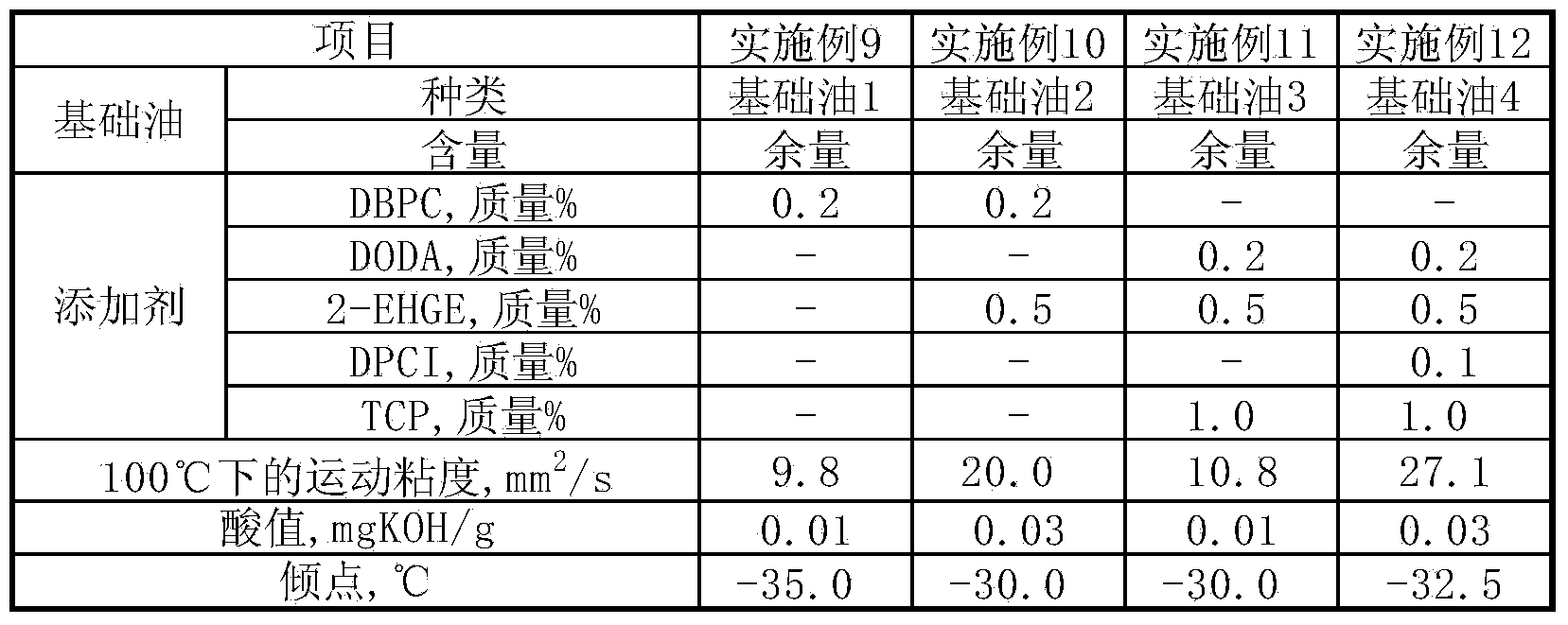

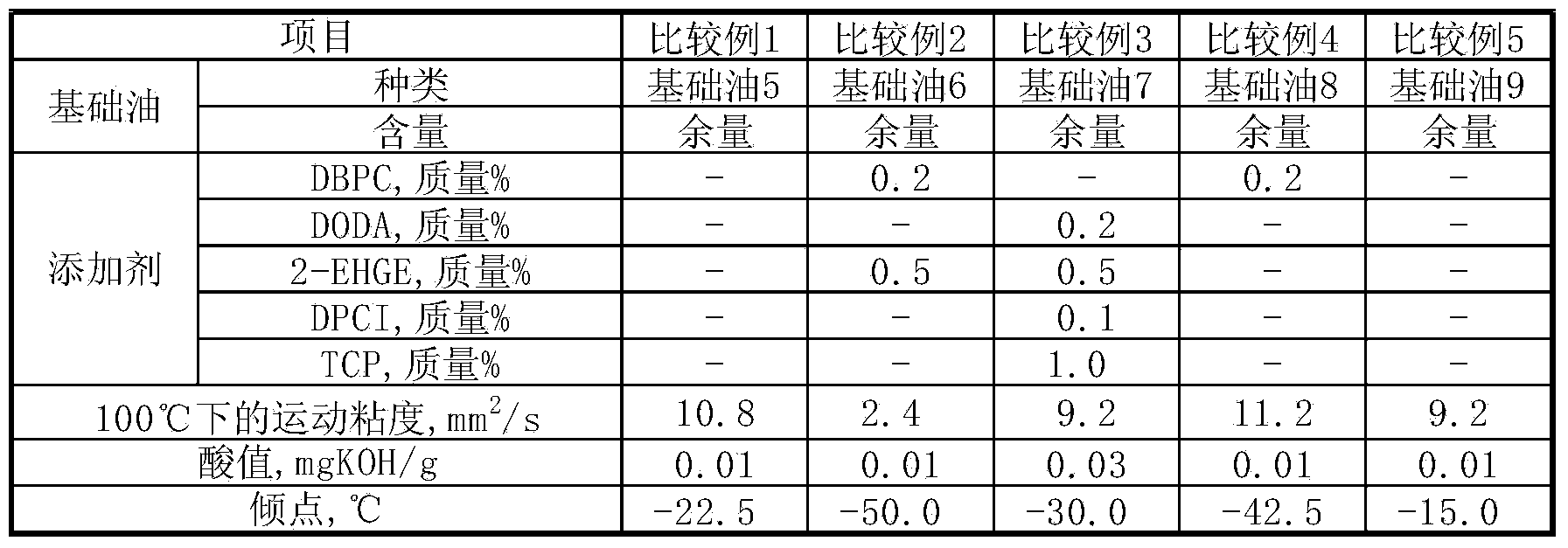

[0041] [First embodiment: Refrigeration machine oil and its manufacturing method]

[0042] The refrigerating machine oil according to the first embodiment of the present invention has a kinematic viscosity at 100° C. of 2 to 50 mm 2 / s, used together with hydrocarbon refrigerants with 2 to 4 carbons, which contain ester intermediates obtained by reacting neopentyl polyols with dibasic acids and further use monohydric alcohols with 1 to 20 carbons or 2 to 20 carbons The complex esters obtained by esterification of fatty acids with an acid value of 0.5 mg KOH / g or less are used as base oils. In addition, the refrigerating machine oil of this embodiment is used together with a hydrocarbon refrigerant containing 2 to 4 carbon atoms, which contains a neopentyl polyol, a dibasic acid, and a monohydric alcohol selected from 1 to 20 carbon atoms and Consisting of at least one type of fatty acid with 2 to 20 carbon atoms, an acid value of 0.5 mg KOH / g or less, and a kinematic viscosity...

no. 2 Embodiment approach

[0075] [Second Embodiment: Working Fluid Composition for Refrigerators]

[0076] The working fluid composition for refrigerators according to the second embodiment of the present invention has a kinematic viscosity at 100° C. of 2 to 50 mm 2 / s refrigerating machine oil and hydrocarbon refrigerants with 2 to 4 carbon atoms, the refrigerating machine oil contains ester intermediates obtained by reacting neopentyl polyols with dibasic acids and further utilizes monohydric alcohols selected from 1 to 20 carbon atoms and A complex ester obtained by esterifying at least one of fatty acids (monovalent chain carboxylic acids) having 2 to 20 carbon atoms and having an acid value of 0.5 mg KOH / g or less is used as a base oil. In addition, another aspect of the working fluid composition for refrigerating machines of the present embodiment is a working fluid composition for refrigerating machines, which contains a refrigerating machine oil and a hydrocarbon refrigerant having 2 to 4 carb...

Embodiment 1

[0081] [Example 1: Manufacture of complex ester A]

[0082] 104 g (1.0 mol) of neopentyl glycol (NPG) was reacted with 219 g (1.5 mol) of adipic acid (AA) at 220° C. for 3 hours to obtain an ester intermediate. 156 g (1.2 mol) of 2-ethylhexanol was added to this ester intermediate, and it was made to react at 220 degreeC for 2 hours, and the carboxyl group which remained in the ester intermediate was esterified. After the reaction finishes, remove the remaining 2-ethylhexanol in the reaction mixture, and then utilize adsorption treatment (clay treatment) to remove trace impurities to obtain the target complex ester (neopentyl glycol, adipic acid and 2-ethylhexyl complex esters of alcohols, hereinafter referred to as "complex esters A").

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com