Hydrophobically-associating polyacrylamide fracturing fluid thickener, preparation method and applications thereof

A polyacrylamide, hydrophobic association technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of insufficient temperature resistance, instability, incomplete gel breaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

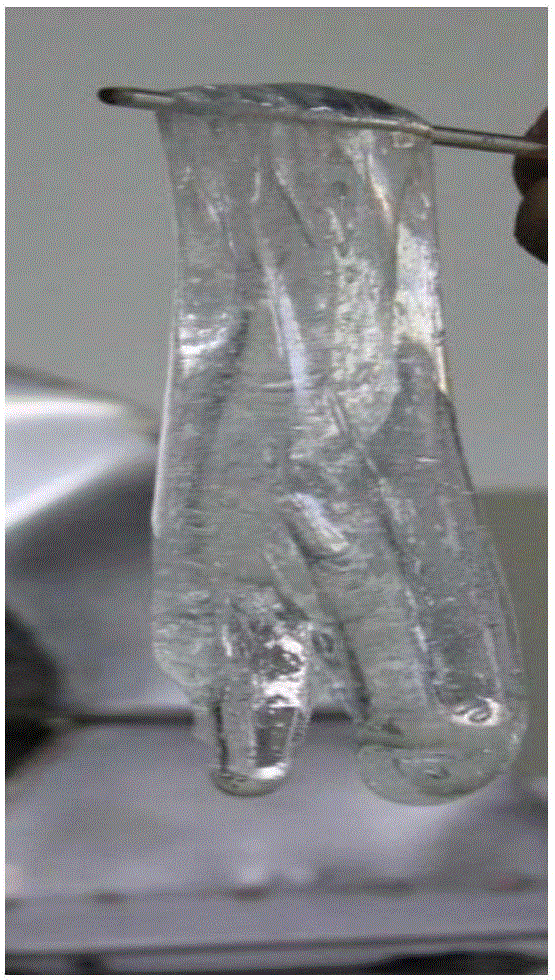

Image

Examples

Embodiment 1

[0041]Dissolve 46g of acrylamide monomer, 32g of AMPS, 1g of sodium acrylamide octadecylsulfonate, and 0.1g of sodium formate in 150g of water to make a mixed aqueous solution, adjust the pH value between 7-12, add it to the reaction kettle, and pass Nitrogen deoxygenation, stirring at the same time, water bath temperature control at 15-25 ℃, continuous nitrogen deoxygenation 30min. Dissolve 0.002g of potassium persulfate, 0.0012g of sodium bisulfite, and 0.0008g of azobisisobutyl ether hydrochloride in 2g of water respectively, and add them dropwise into the reactor, and continue to blow nitrogen and stir. After the viscosity of the polymerization reaction system increases significantly, stop feeding nitrogen after the polymerization reaction starts, and the temperature of the water bath gradually increases with the temperature of the reaction system. When the temperature of the reaction system rises to the highest temperature, control the external circulation temperature of t...

Embodiment 2

[0044] Dissolve 62g of acrylamide monomer, 16g of dimethyl diallyl ammonium chloride, 0.8g of sodium octadecyl acrylamide, 0.004g of dimethylaminoethyl methacrylate, and 0.1g of sodium formate in 150g of water , to prepare a mixed aqueous solution, adjust the pH value between 7-12, add it to the reaction kettle, pass nitrogen gas to remove oxygen, and stir at the same time, control the temperature of the water bath at 15-25 ° C, and continue to pass nitrogen gas to remove oxygen for 30 minutes. Dissolve 0.002g of potassium persulfate, 0.0012g of sodium bisulfite, and 0.0008g of azobisisobutyl ether hydrochloride in 2g of water respectively, and add them dropwise into the reactor, and continue to blow nitrogen and stir. After the viscosity of the polymerization reaction system increases significantly, stop feeding nitrogen after the polymerization reaction starts, and the temperature of the water bath gradually increases with the temperature of the reaction system. When the temp...

Embodiment 3

[0047] Dissolve 54g of acrylamide monomer, 24g of AMPS, 0.01g of vinylpyrrolidone, 0.8g of sodium acrylamide hexadecylsulfonate, 0.1g of sodium formate, and 0.006g of dimethylaminoethyl methacrylate in 150g of water, and prepare a mixture Aqueous solution, adjust the pH value between 7-12, add it to the reaction kettle, pass nitrogen gas to deoxygenate, stir at the same time, control the temperature of the water bath at 15-25 °C, and continue to pass nitrogen gas to deoxygenate for 30 minutes. Dissolve 0.004g of potassium persulfate, 0.0016g of sodium bisulfite, 0.002g of tetramethylethylenediamine, and 0.0008g of azobisisobutyl ether hydrochloride in 2g of water, drop them into the reaction kettle, and continue to blow nitrogen and stir. After the viscosity of the polymerization reaction system increases significantly, stop feeding nitrogen after the polymerization reaction starts, and the temperature of the water bath gradually increases with the temperature of the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com