Bonding type dust suppressant for road dust and preparation method of bonding type dust suppressant

A technology of dust suppressant and binder, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of poor wetting performance of bonded dust suppressant, achieve low cost, reduce loss, and promote the formation of micelles The effect formed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

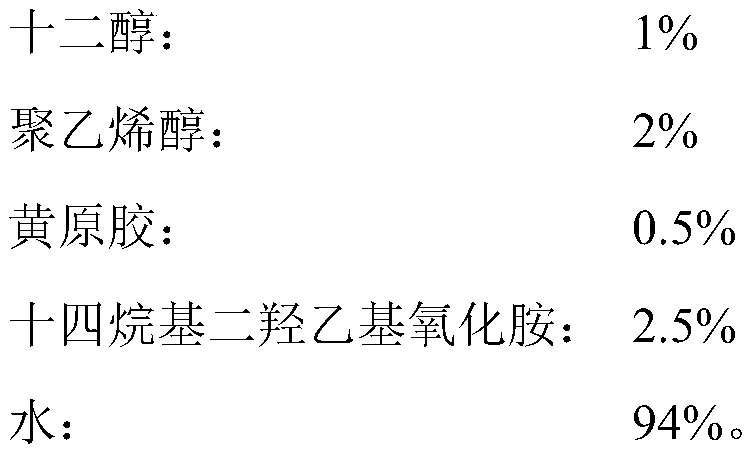

[0030] A bonded dust suppressant for roads in open-pit mines, comprising the following components by weight:

[0031]

[0032] Preparation method: (1) Divide the water into two parts A and B, heat part A to 70°C, and heat part B to 40°C, wherein A is 376g and B is 564g; (2) tetradecyl dihydroxyethyl Add 25g of amine oxide and 5g of xanthan gum in order to dissolve in A, and stir at 50rpm / min for 50min to obtain aqueous solution a; (3) Put 20g of polyvinyl alcohol into part B, and then add 10g of dodecyl alcohol, and mix it at 50rpm / min Stir for 30 minutes to obtain the aqueous solution b; (4) mix the aqueous solutions a and b evenly, and cool to room temperature to obtain the finished product.

[0033] The dust suppressant is diluted 5 times by volume, and the spraying amount is 1.2L / m 2 .

Embodiment 2

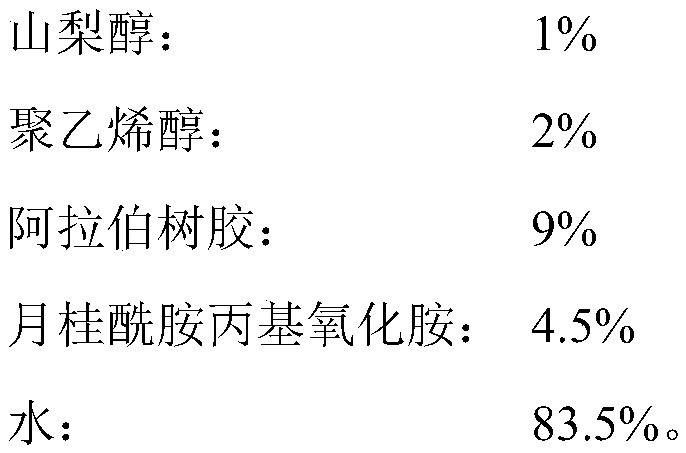

[0035] A bonded dust suppressant for roads in open-pit mines, comprising the following components by weight:

[0036]

[0037] Preparation method: (1) Divide the water into two parts A and B, heat part A to 80°C, and heat part B to 50°C, wherein A is 334g, and B is 501g; (2) lauramide propylamine oxide 10g, Add 90g of gum arabic to A in order to dissolve, stir at 50rpm / min for 50min to obtain aqueous solution a; (3) put 20g of polyvinyl alcohol into part B, then add 10g of sorbitol, and stir at 50rpm / min for 30min to obtain aqueous solution b ; (4) Mix the aqueous solutions a and b evenly, and cool to room temperature to obtain the finished product.

[0038] The dust suppressant is diluted 5 times by volume, and the spraying amount is 1.2L / m 2 .

Embodiment 3

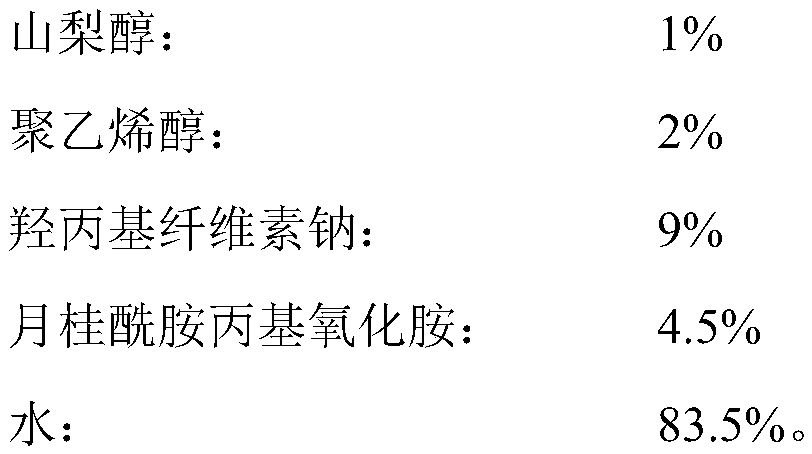

[0048] A bonded dust suppressant for roads in open-pit mines, comprising the following components by weight:

[0049]

[0050] Preparation method: (1) Divide the water into two parts A and B, heat part A to 80°C, and heat part B to 50°C, wherein A is 292g and B is 585g; (2) lauramide propyl hydroxysulfobeet Add 26g of alkali and 52g of locust bean gum in order to dissolve in A, and stir at 100rpm / min for 30min to obtain aqueous solution a; (3) Put 40g of polyvinyl alcohol into part B, then add 5g of sorbitol, and stir at 100rpm / min for 15min , to obtain the aqueous solution b; (4) mix the aqueous solutions a and b uniformly, and cool to room temperature to obtain the finished product.

[0051] The dust suppressant is diluted 5 times by volume, and the spraying amount is 1.2L / m 2 .

[0052] The beneficial effects of the road dust suppressant of the present invention will be described below through test examples.

[0053] According to the method in the Chinese Environmenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com